Dummy bar head special for chamfered mold for continuous casting slabs

A technology of chamfering mold and dummy head is applied in the field of steelmaking and continuous casting, which can solve the problems of redesign and the inability of the dummy head to meet the requirements for the use of chamfering mold, and achieve easy replacement and avoid corner longitudinal crack defects. , Design reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

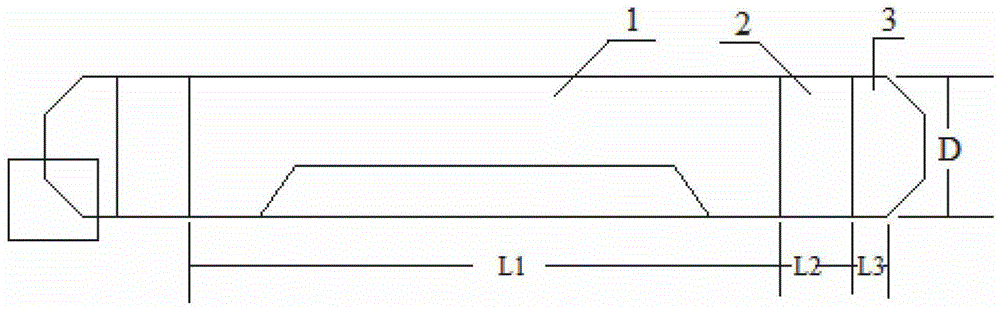

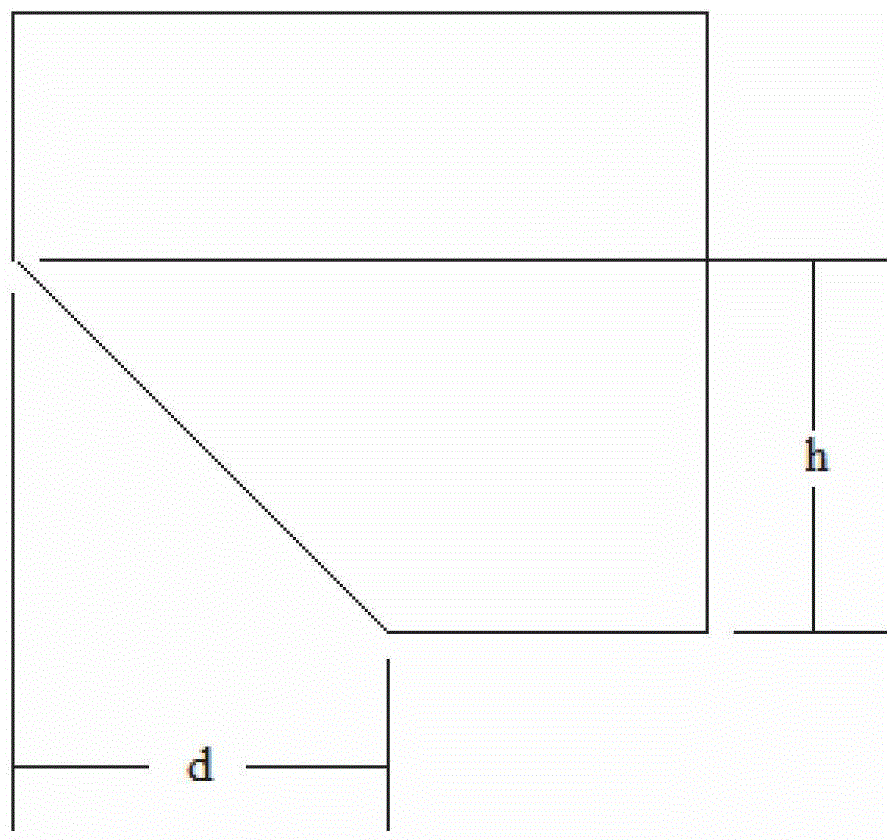

[0017] The present invention comprises a head section 1, a gasket 2, and a chamfering piece 3; the width of the gasket 2 is adjustable, and the chamfering of the chamfering piece 3 corresponds to the chamfering of the crystallizer.

[0018] A steel factory used a chamfering crystallizer when casting a 250mm×1800mm continuous casting slab on a continuous casting machine, and used the special dummy head in the present invention. The size of the head section was 250mm×1400mm, and the size of the gasket was 250mm×350mm. The size of the chamfering piece is 250mm×50mm, and the size of the chamfering position is 30mm×40mm. The surface quality of the cast continuous casting slab is excellent, and the casting process is stable.

[0019] A steel factory used a chamfering crystallizer when casting a 250mm×2400mm continuous casting slab on a continuous casting machine, and used the special dummy head in the present invention. The size of the head section was 250mm×1950mm, and the size of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com