A Secondary Cooling Nozzle Arrangement Method for Silicon Steel Slab Continuous Casting Production

A slab continuous casting and secondary cooling technology, applied in the field of metal casting, can solve the problems of high occurrence of corner cracks, inability to produce silicon steel, restricting the production of silicon steel, etc., to improve uniformity, eliminate corner cracks, and meet cooling strength requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

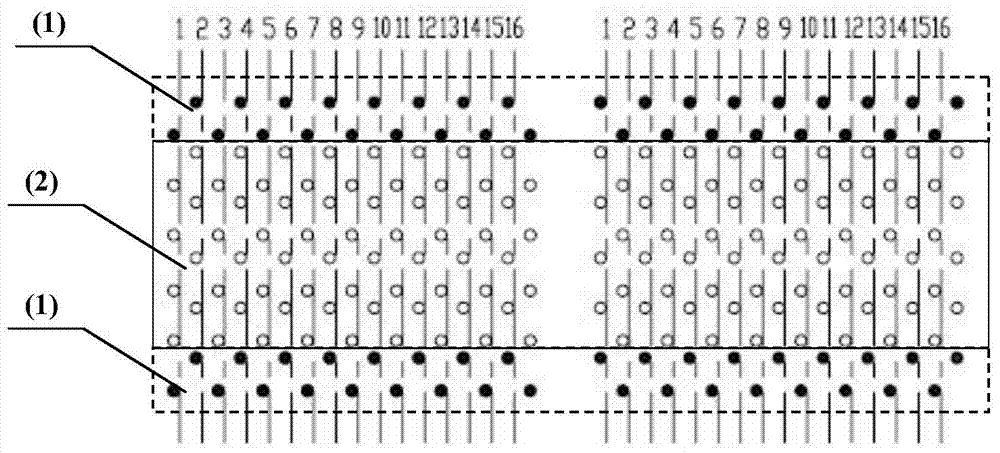

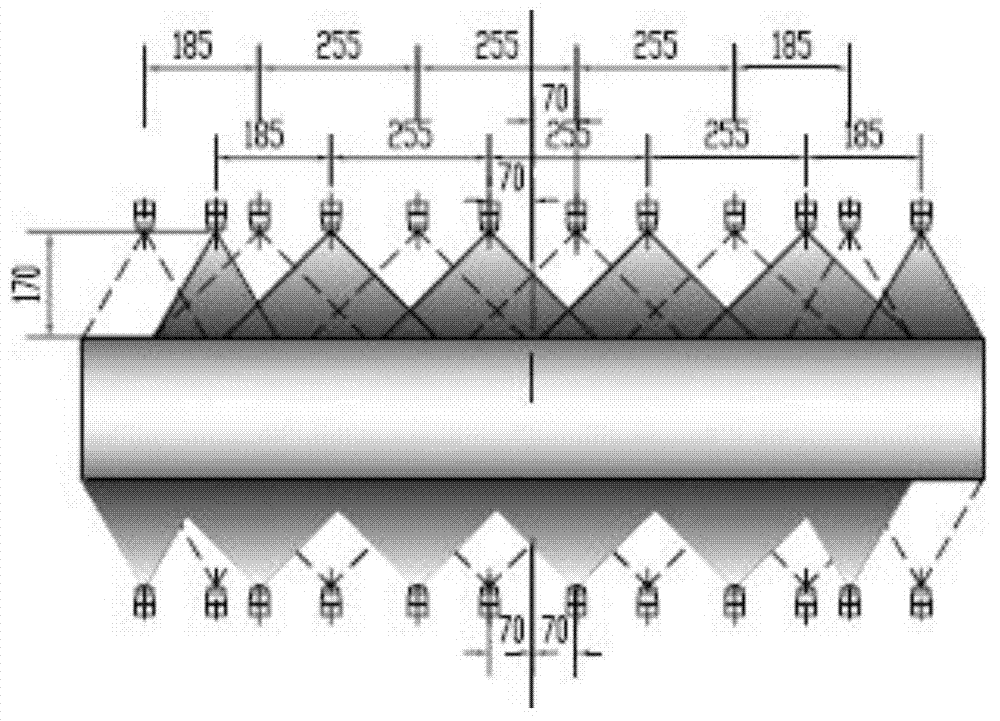

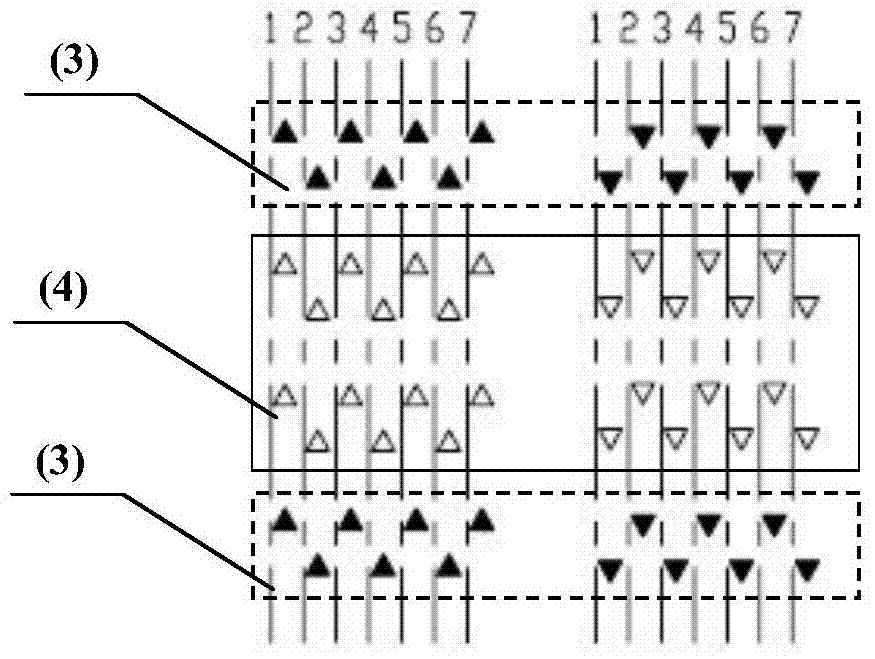

[0030] The method for arranging secondary cooling nozzles for continuous casting of silicon steel slabs proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0031] The invention provides a method for arranging secondary cooling nozzles produced by continuous casting of silicon steel slabs, comprising:

[0032] In the vertical bending section, six nozzles are set in the width direction of the inner arc and outer arc of each roll gap of the continuous casting machine to spray the continuous casting slab, among which, four nozzles are set in the middle, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com