Float process apparatus and method related to melting furnace with two production lines

A float process and production line technology, applied in the field of float glass production process equipment, can solve the problems of unsaturated furnace, poor homogenization, large area, etc., and achieve the effect of meeting the cooling intensity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

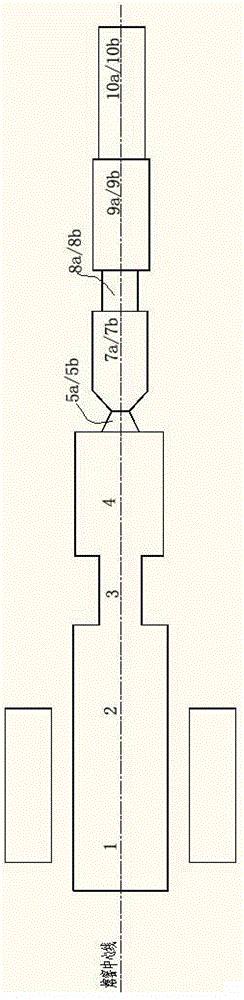

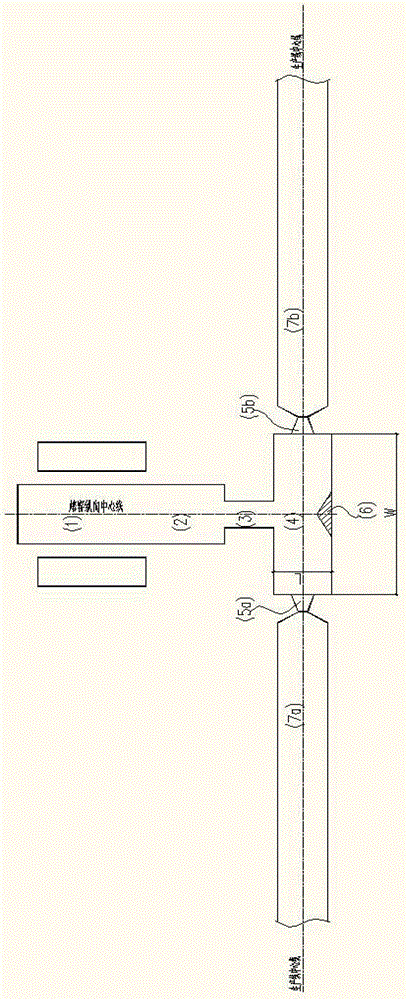

[0024] Float glass production equipment with two production lines: melting furnace, first runner 5a, second runner 5b, first tin bath 7a, second tin bath 7b, first transition roll table 8a, second transition roll table 8b , the first annealing kiln 9a, the second annealing kiln 9b, the first cold end cutting device 10a and the second cold end cutting device 10b. The first runner 5a, the first tin bath 7a, the first transition roller table 8a, the first annealing kiln 9a, and the first cold end cutting device 10a constitute the first production line, while the second runner 5b, the second tin bath 7b, The second transition roller table 8b, the second annealing kiln 9b, and the second cold end cutting device 10b constitute the second production line. The interior of the melting furnace used is composed of a melting zone 1, a refining zone 2 of the melting furnace, a neck 3 and a cooling part 4 of the melting furnace.

[0025] The connection relationship between each device is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com