Secondary cooling nozzle of billet continuous casting machine and arrangement method thereof

A billet continuous casting and nozzle technology, which is applied in the field of metallurgy and continuous casting, can solve problems such as uneven billet shell temperature, affecting the secondary cooling effect, water and air pipe leakage, etc., achieve small surface temperature fluctuations, improve cooling uniformity, crystallization fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

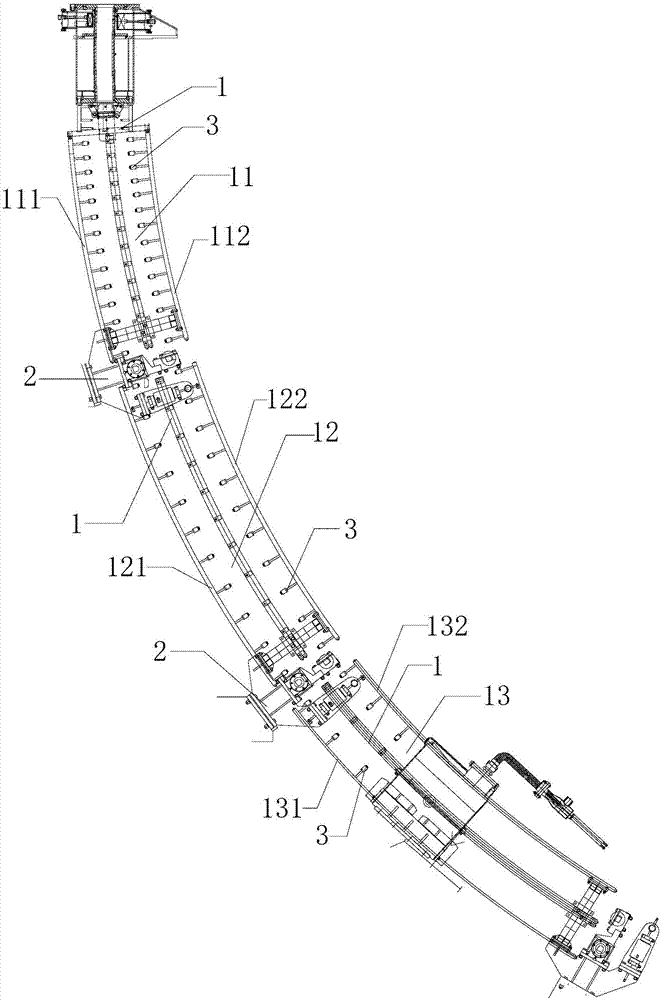

[0019] This embodiment provides a secondary cooling nozzle of a billet continuous casting machine, which includes a foot roll 1 and a connecting valve 2. The secondary cooling nozzle of a billet continuous casting machine is designed in an arc shape as a whole. The foot roll 1 includes a first foot roll section 11, a second The second foot roll section 12 and the third foot roll section 12, the first foot roll section 11 and the second foot roll section 12 and the second foot roll section 12 and the third foot roll section 13 are separated and connected by a connecting valve 2, The first foot roller section 11, the second foot roller section 12 and the third foot roller section 13 are all composed of three rows of left end foot roller, middle end foot roller and right end foot roller arranged in parallel. The left end foot roller of the first foot roller section 11 111 and the right end foot roller 112 are relatively provided with 12 nozzles 3, the left end foot roller 121 of t...

Embodiment 2

[0026]This embodiment provides a secondary cooling nozzle of a billet continuous casting machine, which includes a foot roll 1 and a connecting valve 2. The secondary cooling nozzle of a billet continuous casting machine is designed in an arc shape as a whole. The foot roll 1 includes a first foot roll section 11, a second The second foot roll section 12 and the third foot roll section 12, the first foot roll section 11 and the second foot roll section 12 and the second foot roll section 12 and the third foot roll section 13 are separated and connected by a connecting valve 2, The first foot roller section 11, the second foot roller section 12 and the third foot roller section 13 are all composed of three rows of left end foot roller, middle end foot roller and right end foot roller arranged in parallel. The left end foot roller of the first foot roller section 11 111 and the right end foot roller 112 are relatively provided with 12 nozzles 3, the left end foot roller 121 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com