Oil well plugging device

A plugging device and oil well technology, applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as difficulty in opening wells, easy absorption of wellbore by killing fluid, and cold damage to oil layers, etc., to avoid Killing operation, improving the effect of steam huff and puff, and improving the effect of steam heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

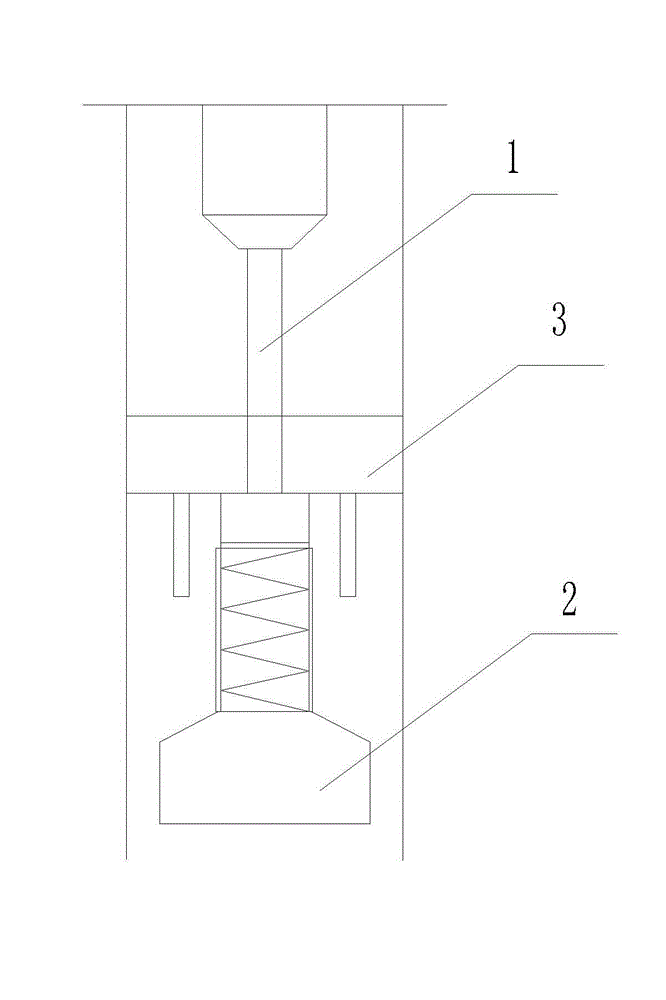

[0011] An oil well plugging device, a pipe string is arranged inside the casing, a switch connection device 1 and a connecting rod 3 are arranged in turn above the pipe string, the connecting rod 3 is movable inside the switch connection device 1, and the lower part of the connecting rod 3 passes through the spring 2 is connected with the pipe column, and the lower part of the switch connection device 1 is open, and its cross-sectional area is larger than that of the spring column 2.

[0012] Under normal conditions, the spring column 2 is in the released state, and the connecting rod 3 seals the spring column 2 on the switch connection device 1, which can effectively prevent the well fluid from gushing. When gas injection is required, the gas pours in from the upper connecting rod 3 , the spring column 2 is tightened under the action of atmospheric pressure, and the gas flows from the switch connection device 1 into the well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com