a dispensing column

A technology of pipe injection and pipe string, applied in the field of oil and gas field exploitation, can solve the problems of high construction cost, inability to trip the pipe string without killing the well, and achieve the advantages of reducing the construction cost, avoiding the killing operation, and avoiding the loss of formation water injection energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

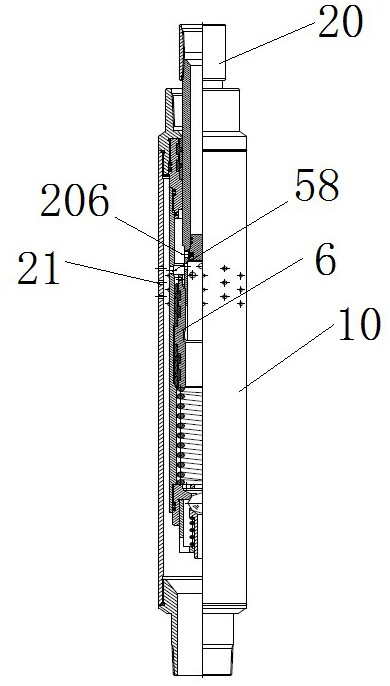

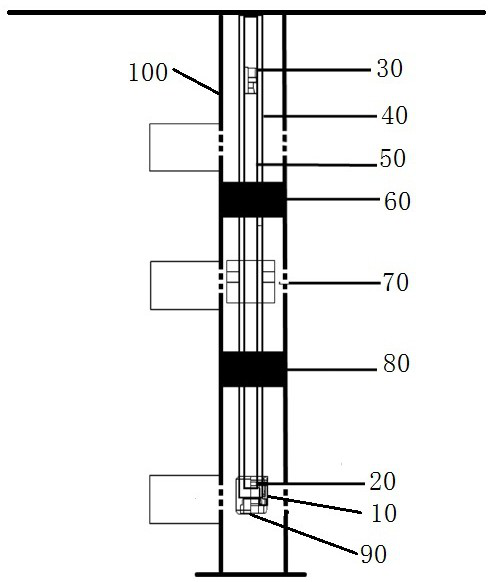

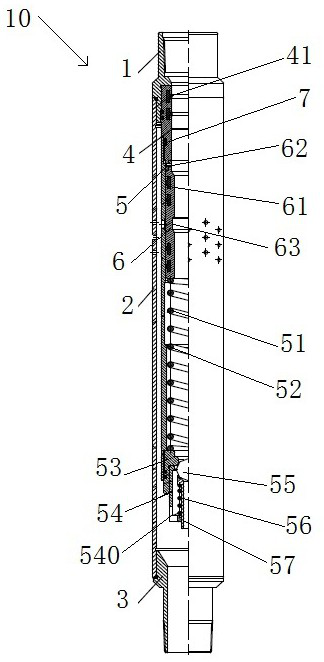

[0034] A specific embodiment of the dispensing column of the present invention, such as Figure 1 to Figure 8 As shown, a distributing pipe string includes an outer pipe and an inner pipe located inside the outer pipe, and an annular cavity for injecting water into the upper formation is formed between the inner pipe and the outer pipe, wherein the outer pipe includes sequentially arranged from top to bottom The large pipe string 40, the first packer 60, the one-way valve 70, the second packer 80, the downhole switch 10 and the plug 90, the inner pipe includes the preset mandrel 30 arranged in sequence from top to bottom, the small pipe The column 50 and the intubation tube 20, the bottom water injection channel and the movable spool 6 are provided on the downhole switch 10, and the driving part 203 is provided on the intubation tube 20, and the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com