Inter-shaft permanent magnet coupling mechanism

A permanent magnet coupling, shaft-to-shaft technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

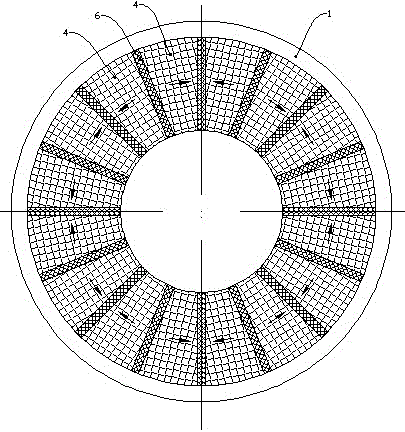

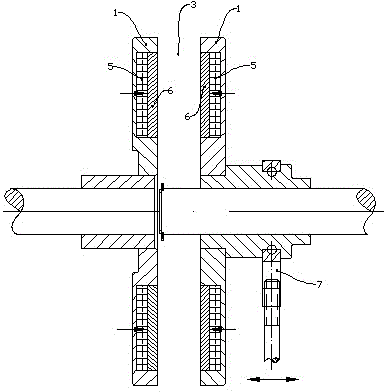

[0012] As shown in the figure, the inter-shaft permanent magnet coupling mechanism of the present invention includes two permanent magnet rotors 1 coaxially arranged, and permanent magnets are respectively distributed on the two permanent magnet rotors 1; the two permanent magnet rotors 1 are discs The structure and the front end faces are opposite to form an air gap 3; the permanent magnet on the permanent magnet rotor includes a main magnet 4 and an auxiliary magnet 5; a plurality of main magnets 4 are distributed along the circumference on the end face of the permanent magnet rotor, between adjacent main magnets A magnetic conductor 6 made of magnetic permeable material is placed, and an auxiliary magnet 5 is arranged on the side of each magnetic conductor 6 away from the air gap; ) is located in the circumferential direction of the permanent magnet rotor 1, and the magnetic pole directions of adjacent main magnets face or face each other; the magnetic pole direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com