Side punching die

A punching and die technology, applied in the field of side punching die for lampshade, can solve the problems of inconvenient positioning, high labor intensity, low work efficiency, etc., so as to reduce production cost and labor intensity, and avoid inaccurate position of side holes. , Improve the effect of product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

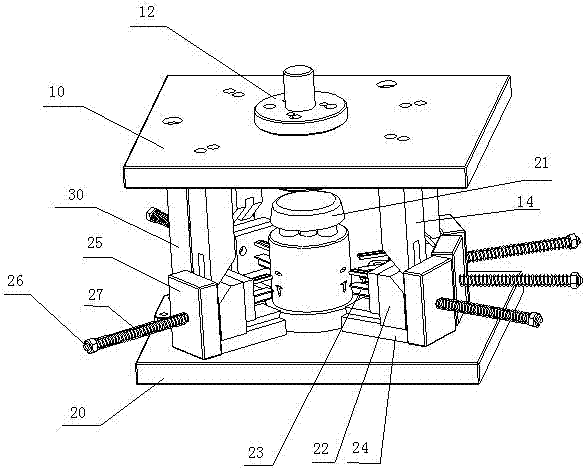

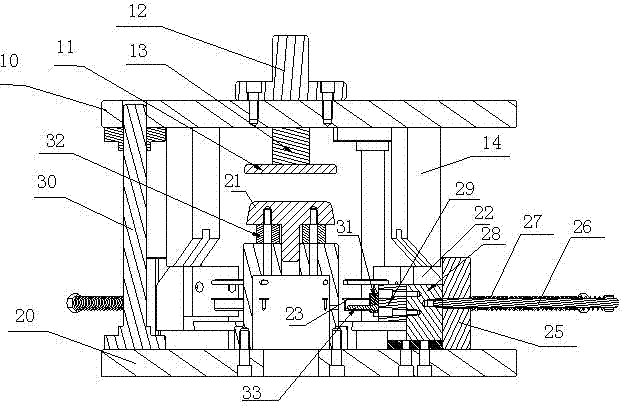

[0020] see figure 1 and figure 2 , the present embodiment is a side punching die for punching side holes on the side of the lampshade, which includes an upper template 10 and a lower template 20 and a guide post 30 connecting the upper and lower templates, on the upper surface of the upper template 10 Die Bing 12 is installed, and its lower surface is equipped with hold-down plate 11 by buffering part 13, and what this buffering part 13 has adopted is uric acid, plays buffering effect, and reaches to press the lampshade to be punched tightly. Five pusher columns 14 are evenly arranged around the upper template 10, which correspond to the five punching needle sliders 22 installed on the lower template 20, so that they can be evenly divided into f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com