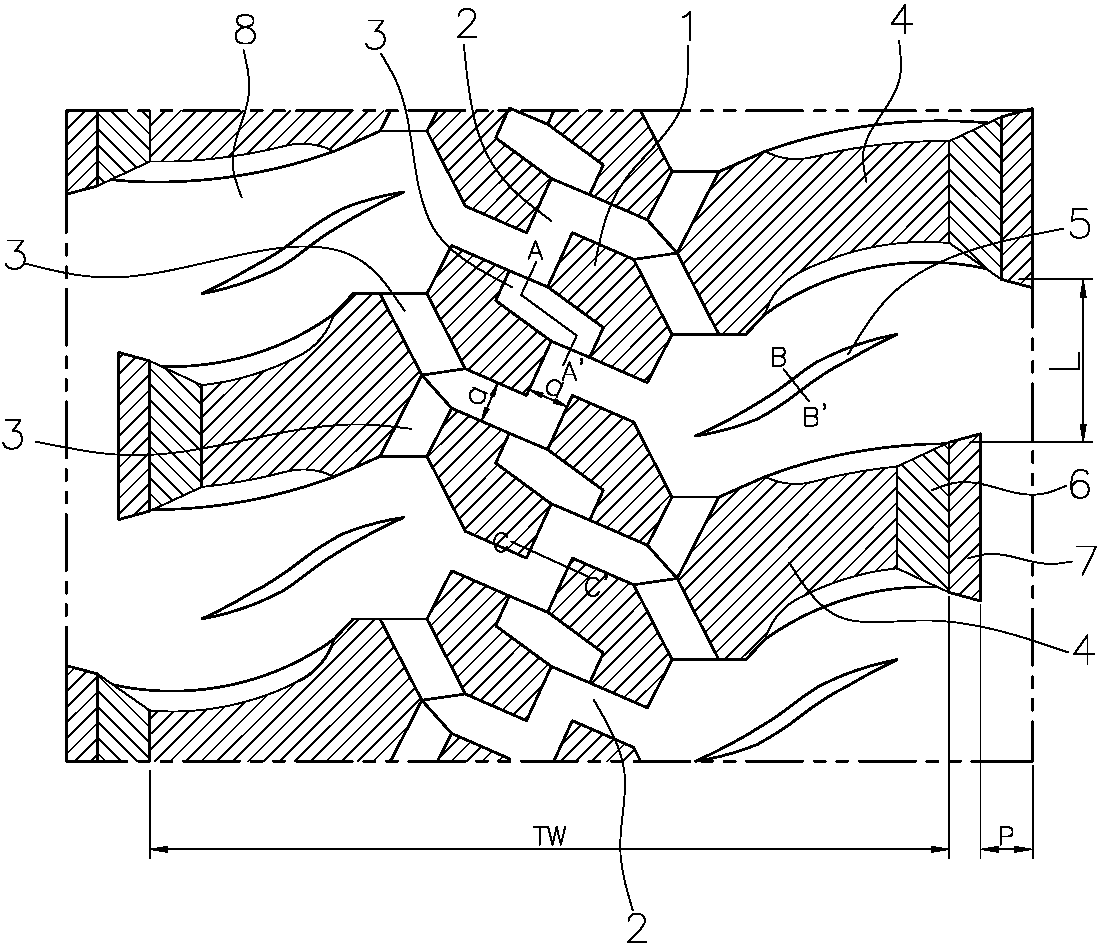

Cross-country tire tread pattern structure

A technology for tread patterns and off-road tires, applied in the field of off-road racing tires, can solve problems such as easy slippage, affect pattern drainage, mud discharge performance, reduce tread coverage, etc., and achieve the effect of improving fast turning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

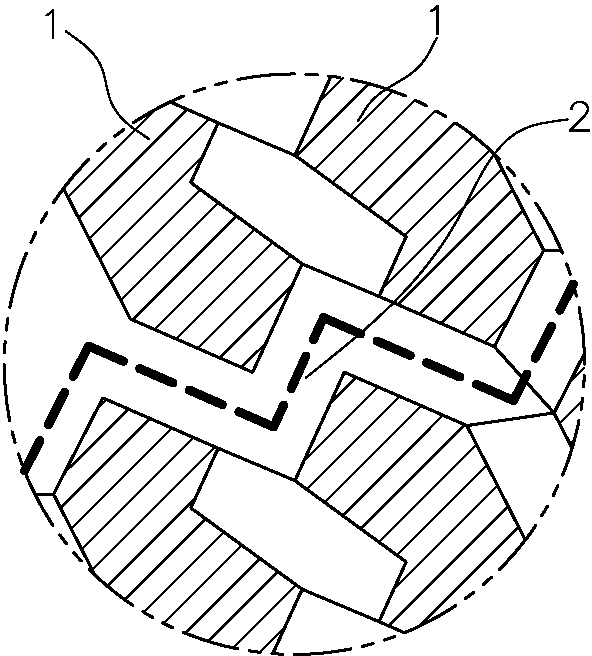

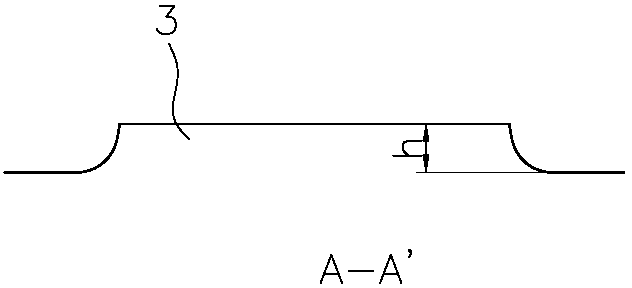

[0022] As shown in Figures 1 to 6B, the present invention discloses an off-road tire tread pattern structure, which consists of a plurality of pattern units distributed on the tire tread, and each pattern unit includes a central pattern block group distributed along the tire circumference and a Circumferentially distributed shoulder pattern block groups, two shoulder pattern blocks 4, one long and one short, are distributed at intervals in the circumferential direction of the shoulder, and each central pattern block 1 and shoulder pattern block 4 are connected by reinforcing ribs 3 to form Z-shaped pattern structure, at the bottom of each shoulder pattern groove 8, there are ribs 5 at the bottom of the groove along the transverse direction; both sides of the shoulder pattern block 4 are designed in a stepped shape, and the outer end surface is composed of an upper end surface 6 and a lower end surface 7 The two end surfaces overlap to form.

[0023] Each shoulder pattern block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com