pole core

A technology of magnetic pole core and magnetic pole, applied in the direction of magnetic circuit shape/style/structure, etc., can solve the problems of easily damaged magnetic pole coil, difficult stacking of pole shoes, and high manufacturing cost, so as to improve motor performance, improve product quality, and reduce tooling effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

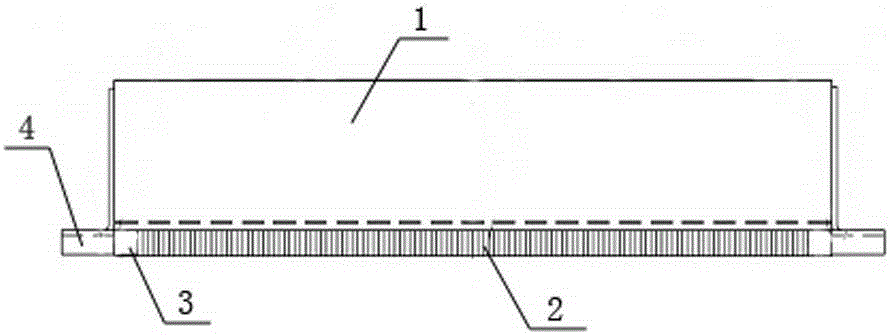

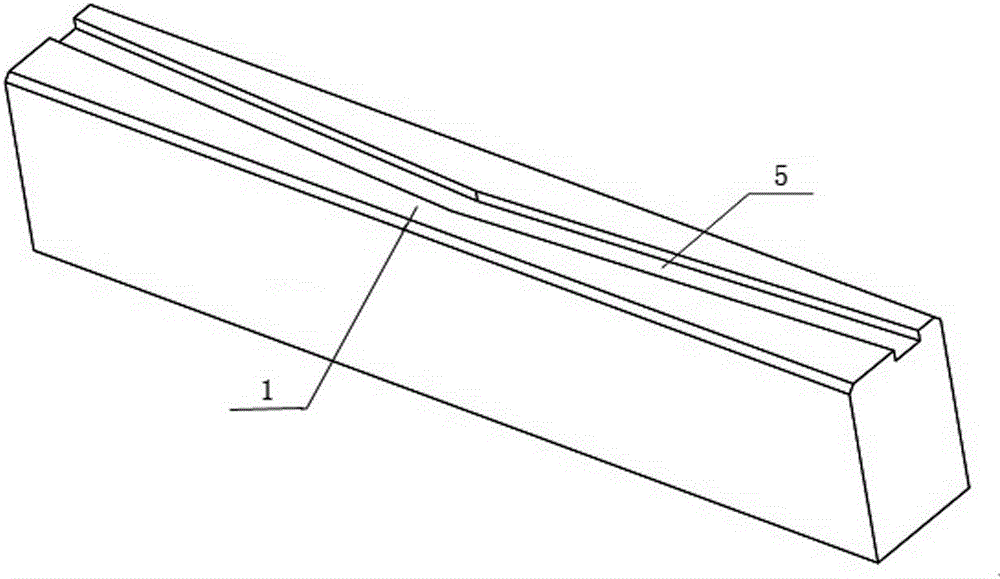

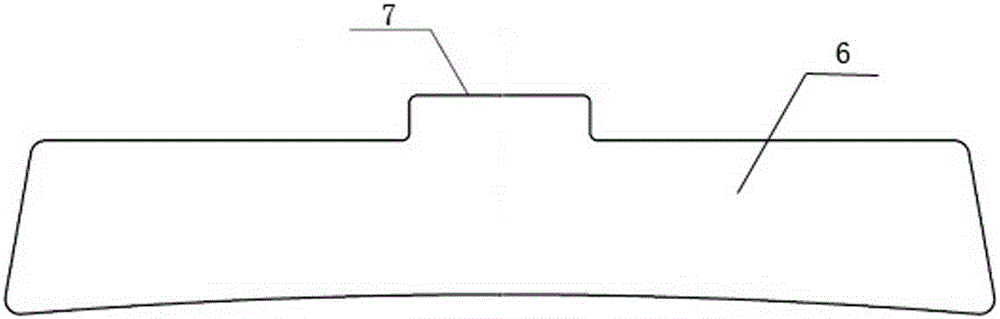

[0022] The magnetic pole core includes a magnetic pole body 1, on which is welded a pole piece 2 formed by stacking a pole piece punching piece 6, and a positioning tab 7 extends on the edge of the pole piece punching piece 2 in contact with the magnetic pole body 1, The contact surface of the magnetic pole body 1 and the pole piece 2 is provided with a herringbone-shaped guide groove 5 along the length direction. The angle between the hypotenuse of the guide groove 5 and the transverse center axis of the surface where it is located is δ, and this angle δ is an electromagnetic design. In order to weaken the tooth harmonic potential, the pole piece should be inclined relative to the axis of the magnetic pole iron core when the pole piece is fixed on the magnetic pole pole. In the above-mentioned magnetic pole iron core, pole piece baffles 3 are stacked on both ends of the pole piece 2 , and the shape of the pole piece baffle 3 is the same as that of the pole piece punching piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com