Die replacing vehicle

A mold replacement and mold technology, applied in household appliances, other household appliances, household components, etc., can solve the problems of danger and high labor intensity, and achieve the effects of convenient operation, reduced labor intensity, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

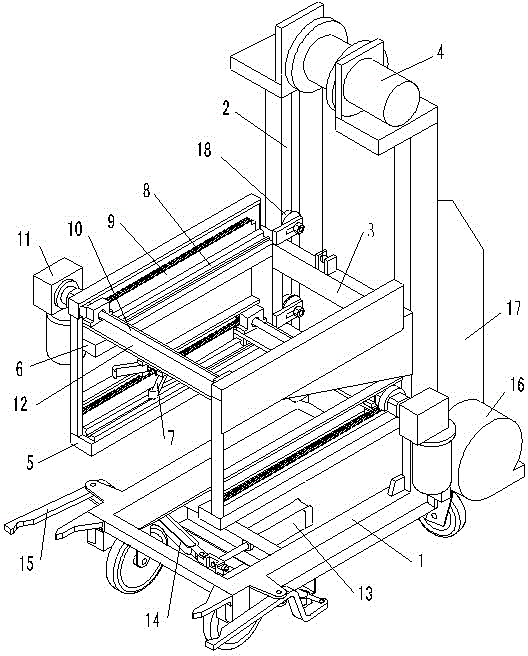

[0013] As shown in the drawings, the mold replacement vehicle of the present invention includes a vehicle frame 1, a lifting seat 2, a lifting device and a positioning device. Vehicle frame 1 is welded by section bar such as channel steel angle steel, and its bottom is equipped with traveling wheel, specifically bottom front end is equipped with directional wheel, and rear end is equipped with universal wheel. The rear portion of vehicle frame 1 is provided with lifting guide rail 2, and the top of lifting guide rail 2 is equipped with lifting device, and lifting device adopts electric winch 4. Lifting seat 3 is welded and processed by channel steel profiles, and its side is provided with lifting guide wheel 18, which is installed on lifting guide rail 2 through lifting guide wheel 18, and is connected with electric hoist 4 through a wire rope, and is driven by electric hoist 4 to lift Seat 3 can move up and down along lifting guide rail 2. The lifting guide wheel 18 adopts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com