Shearing device for testing soil strength

A shearing device and strength technology, applied in the direction of using a stable shearing force to test the strength of materials, can solve problems such as incomplete matching, and achieve the effect of ensuring authenticity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Next, a specific implementation process of the present invention will be described in detail by way of example, which will also clearly show the features and advantages of the present invention.

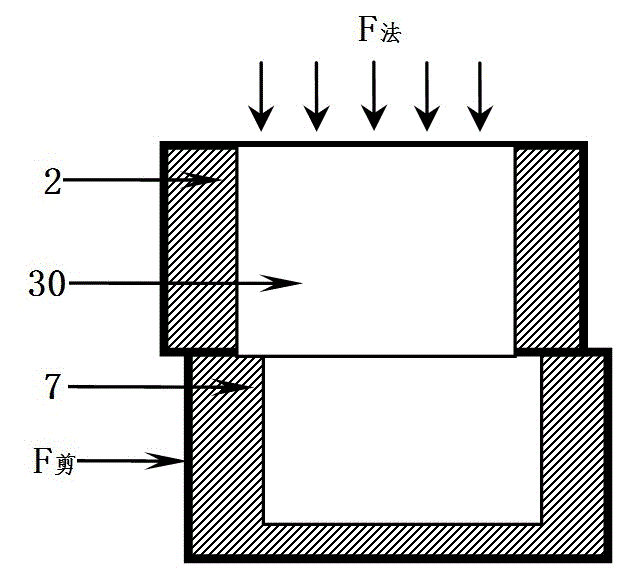

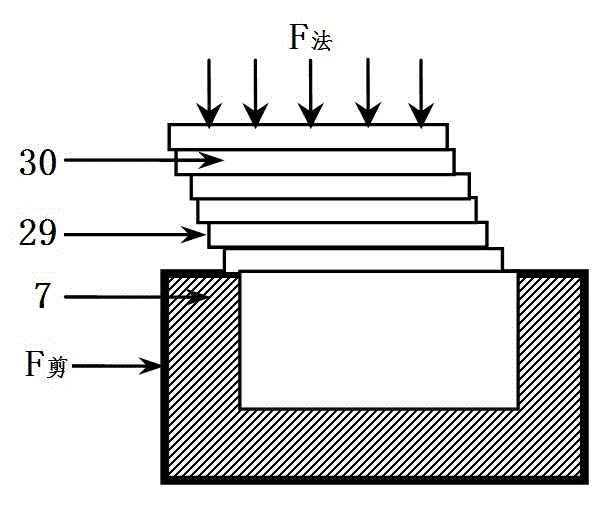

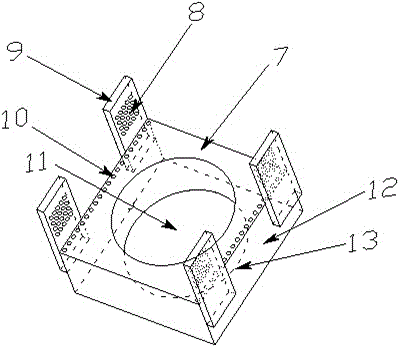

[0047] A shear device for testing the strength of soil, such as Figure 9 As shown, it is mainly composed of an upper shear box 2, a lower shear box 7, and shear sliding parts 14, 19, 22, 25. The upper shear box 2 is connected with the reaction force support 1 as a whole, as Figure 4 As shown, the middle packing cylinder of the upper shear box 2 is cylindrical and penetrates from top to bottom, that is, the bottom surface 5 of the upper shear box and the bottom contour line 6 of the packing cylinder of the upper shear box are on the same plane. Steel balls are embedded inside the spherical hole 4 to reduce friction. The upper shear box is except that the packing cylinder 3 is a cylindrical hole, and all the other parts are entities, which can be made of stainless steel or ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com