Robust fuzzy control method for hydraulic loop based on uncertain discrete model

An uncertain, discrete model technology, applied in the field of strip rolling, can solve the problems of hydraulic looper robust fuzzy, unable to eliminate the steady-state error of system parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

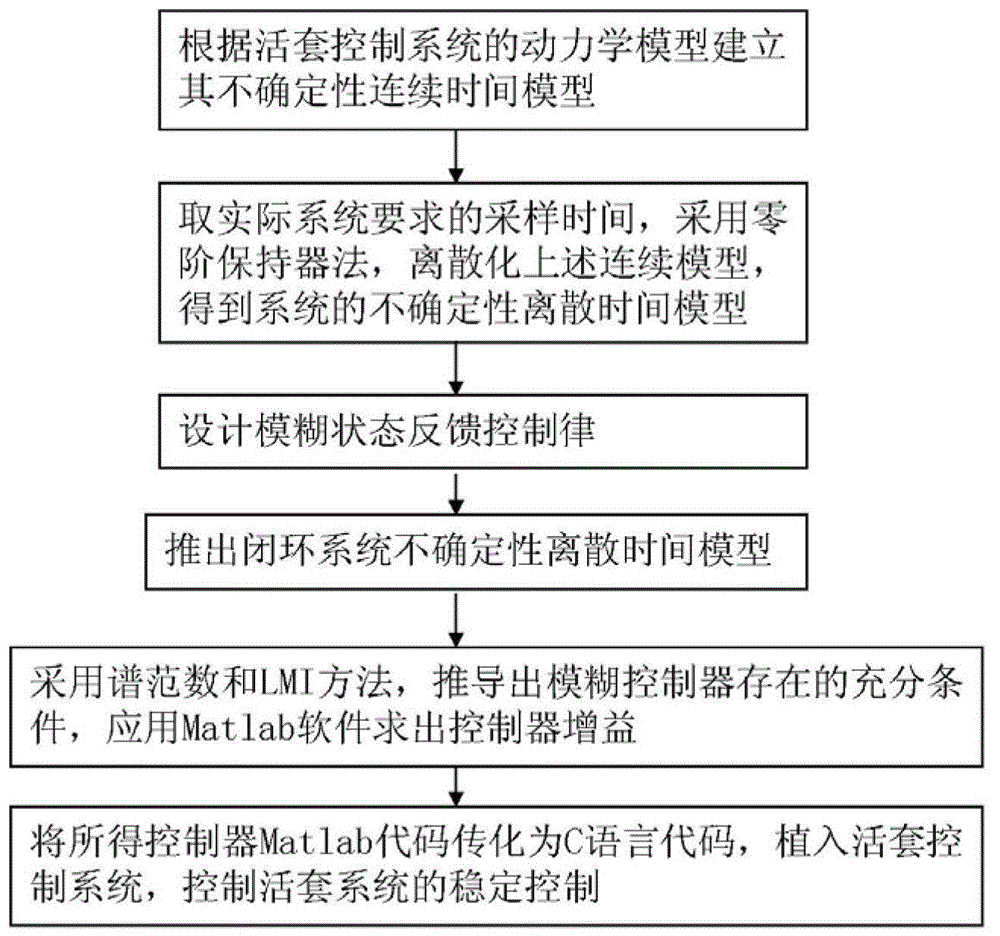

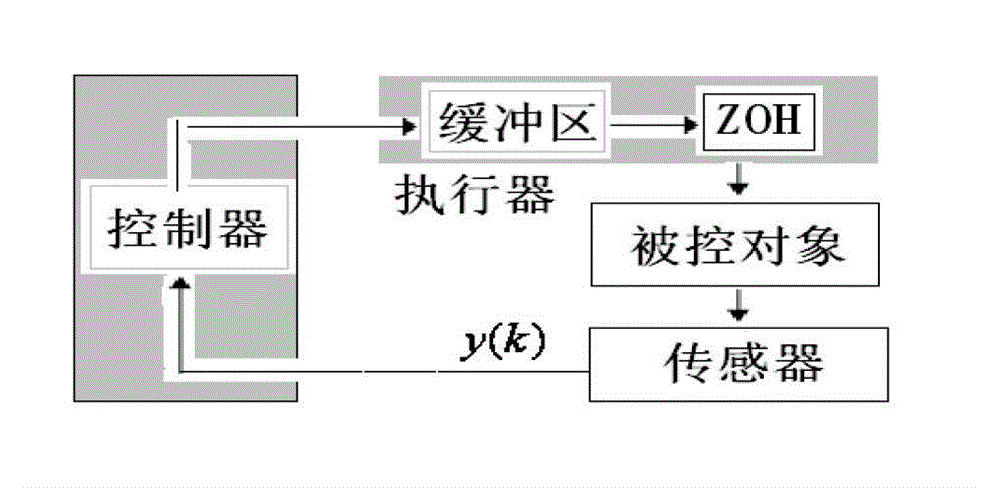

[0053] Adopt the present invention to control the looper control system below, in conjunction with Fig. 1 and figure 2 Illustrate implementation method of the present invention, concrete process is as follows:

[0054] Step 1: According to the existing looper dynamic equation, establish a continuous-time model of the looper control system.

[0055] The actual strip hot rolling hydraulic looper control system generally has irregular frequency spectrum disturbance and system parameter uncertainty, and it is difficult to establish an accurate mathematical model. However, most of the existing controller design methods do not consider the parameter uncertainty, so they cannot directly It is applied to the production site or the control precision is low.

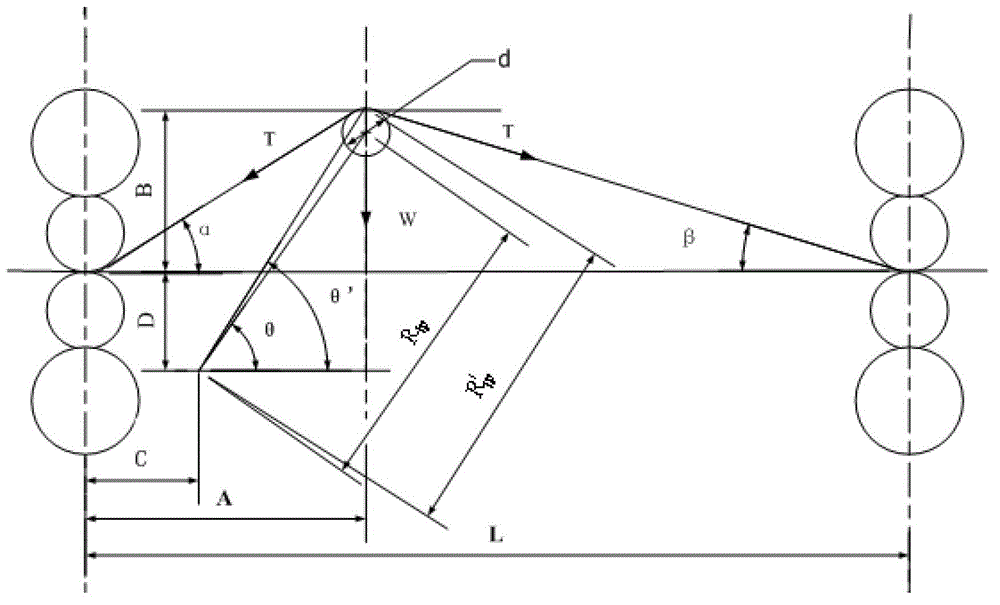

[0056] The force analysis diagram of the looper device during strip rolling is as follows image 3 As shown, according to the existing looper dynamics equation, the uncertainty continuous time model of the looper control system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com