Gib injection mold for joint part

A technology for parts and concave characters, which is applied in the field of molds for injection molding of concave characters on joint parts, can solve the problems of low processing efficiency, unstable concave characters, uneven definition of indent characters, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

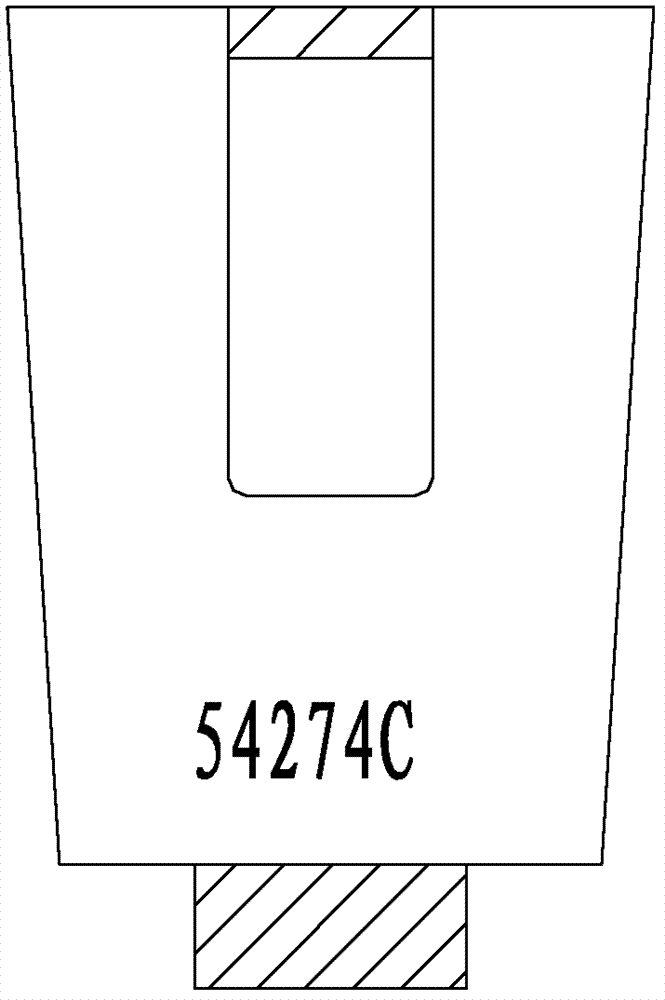

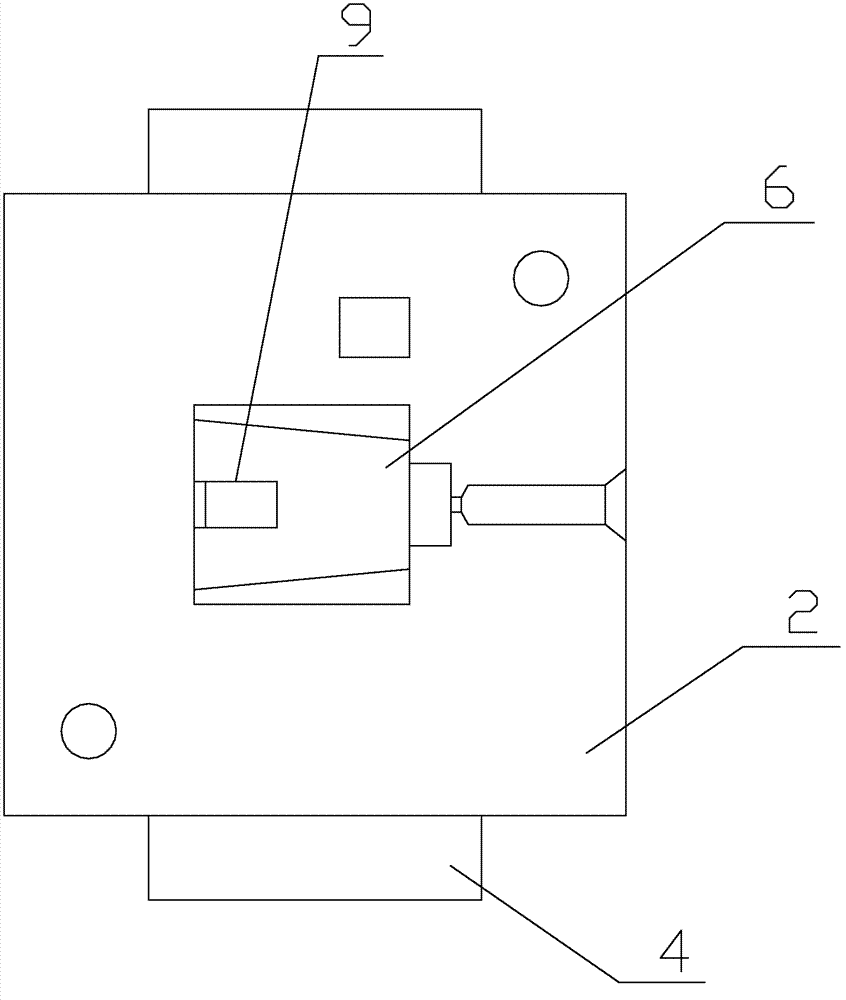

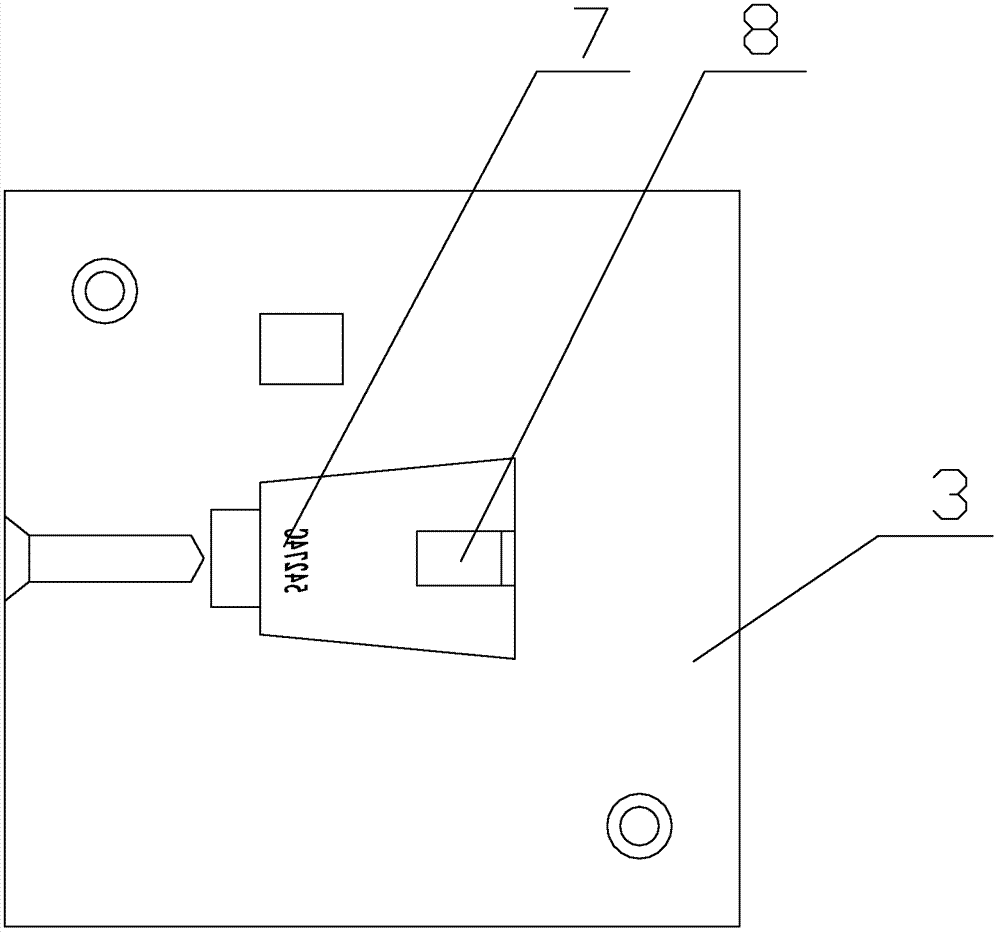

[0018] see Figure 2-4 As shown, a mold for the injection molding of concave characters on joint parts includes a movable template 2, a fixed template 3 that can closely cooperate with the movable template 2 to form a closed cavity, and a movable mold base 1 fixedly connected with the movable template 2 1. The taking module 4 that can be arranged up and down on the movable mold base 1, the upper end surface of the taking module 4 is fixedly connected with a die 6, and the movable template 2 is provided with a first groove corresponding to the die 6, The die 6 is matedly inserted into the bottom of the first groove, and the fixed template 3 is correspondingly provided with a second groove, so that the first groove, the second groove, and the die 6 are matched to form a mold that is compatible with the desired injection molding. The mold cavity with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap