Static iron core and motor vehicle electric horn provided with the static iron core

A technology of electric horns and static iron cores, which is applied in the direction of sound-generating instruments and instruments, can solve problems such as difficult implementation of technological means, and achieve the effects of reducing horn failures, simple installation and debugging, and reducing waterproof costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

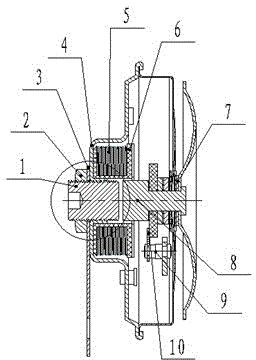

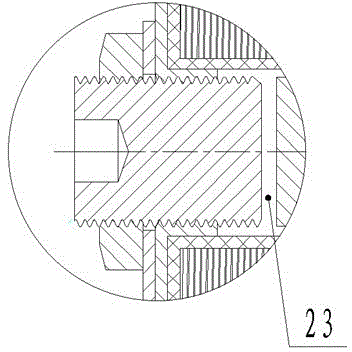

[0036] Below in conjunction with accompanying drawing, the present invention is further described: as Figure 5 , Image 6 As shown, a static iron core for a basin-type motor vehicle electric horn includes a thin part 15 and a thick part 16, and the thin part 15 is externally provided with an external thread 17 for connecting with the chassis, and the diameter of the thick part 16 is approximately Smaller than the diameter of the inner hole in the center of the bobbin.

[0037] A pot-type motor vehicle electric horn, comprising a chassis 4, a coil 5, a coil bobbin 6, a diaphragm 7, a moving armature 8, a contact intermittent mechanism 10 and a static iron core 13, and the coil bobbin 6 is installed on the chassis 4 In the inner cavity, one end of the static iron core 13 is placed in the central inner hole of the coil bobbin, and is in dynamic fit with the central inner hole of the coil bobbin 6 with a small gap, and the other end is screwed to the chassis 4, which One end of...

Embodiment 2

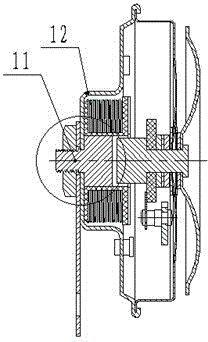

[0044] Such as Figure 7 , Figure 8 As shown, a static iron core for a snail-shaped motor vehicle electric horn includes a thin portion 15 and a thick portion 16, the thin portion 15 is externally provided with an external thread 17 for connecting with the chassis, and the diameter of the thick portion 16 is approximately Smaller than the diameter of the inner hole in the center of the bobbin.

[0045] A snail-shaped motor vehicle electric horn, comprising a chassis 4, a coil 5, a bobbin 6, a diaphragm 7, a moving armature 8, a contact intermittent mechanism 10 and a static iron core 13, and the bobbin 6 is installed on the chassis 4 In the inner cavity, one end of the static iron core 13 is placed in the central inner hole of the coil bobbin, and is in dynamic fit with the central inner hole of the coil bobbin 6 with a small gap, and the other end is screwed to the chassis 4, which One end of the inner hole placed in the center of the bobbin 6 has a larger diameter, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com