Punching die for terminal block

A terminal block and plate punching technology, applied in the field of terminal block plate punching molds, can solve the problems of difficult operation, reduce production efficiency, increase labor intensity, etc., and achieve the effects of simple structure and assembly, reducing labor intensity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

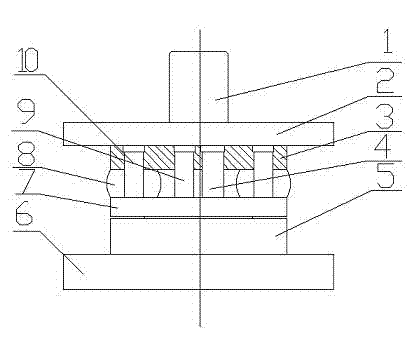

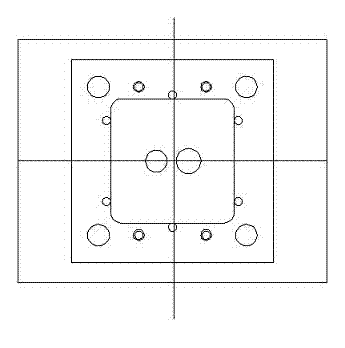

[0012] Such as figure 1 and figure 2 As shown, the punching die for the terminal seat board includes a die handle 1, an upper die 2, a fixed plate 3, a first punch 4, a die 5, a lower die 6, a stripping plate 7, a second punch 9 and a guide post 10. The mold handle 1 is installed on the upper template 2, the fixed plate 3 is installed on the bottom of the upper template 2, the die 5 is installed on the lower template 6, the stripping plate 7 is installed on the die 5, the first punch 4, the second Two punches 9 and guide posts 10 are installed between the upper formwork 2 and the discharge plate 7, there are 4 guide posts, 4 rubbers, and rubbers 8 are arranged on both sides of the guide post 10, a terminal seat plate of the present invention The punching die has simple and precise structural assembly, long service life, convenient operation and accurate positioning during use, thus reducing labor intensity and improving production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com