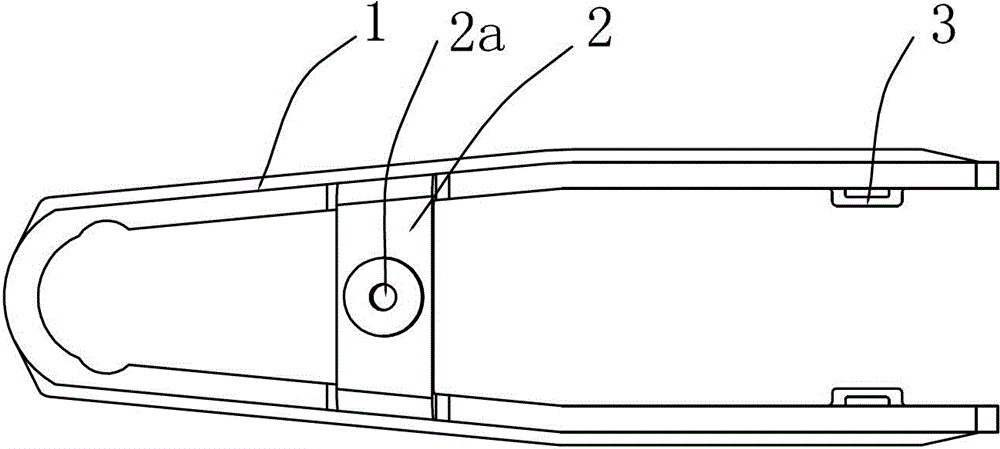

[0003] The name in the prior art is "motorcycle chain guard", and the Chinese utility model patent No. 20620112068.X discloses a motorcycle chain guard. The inside of the chain guard is provided with a corresponding mounting hole on the flat fork. Two rubber positioning bosses, the positioning boss is composed of a transition section and a spherical head, the transition section and the spherical head are integrally structured, the

diameter of the spherical head is slightly larger than the

diameter of the mounting hole of the flat fork, and the

diameter of the transition section is slightly smaller than the diameter of the mounting hole of the flat fork. Utilizing the self-elasticity of the rubber, the positioning boss on the guard card can be pressed into the mounting hole on the main body of the flat fork with a little force during installation, and a relatively large force is required to withdraw it. This utility model solves the problem of the chain The guard card is installed by screws, and the mounting screw is exposed outside the chain guard card, which has the disadvantages of contact and friction with the chain

However, by the disclosure of the invention attached image 3 , 4 It can be seen that the front end of the motorcycle chain guard is set on the flat fork, and the rear end is connected with the positioning hole on the flat fork through the positioning boss. This structure has the following shortcomings: one is that the front end of the motorcycle chain guard is set on the On the flat fork, after long-term use, there will be a gap between the motorcycle chain guard and the flat fork, so it will become loose and the positioning effect will be poor; the second is to use the rubber positioning boss to connect with the positioning hole on the flat fork for positioning. When the rubber is soft, reliable positioning cannot be achieved. At the same time, the rubber positioning boss is also easily damaged. When the rubber is hard, due to the

interference fit between the spherical head and the positioning hole,

assembly is difficult, and it is easily deformed and scrapped.

But this invention patent also has the following deficiencies: the one, because the front end arc of motorcycle chain guard card is enclosed within on the shaft sleeve outer circle of motorcycle flat fork, the cooperation of motorcycle chain guard card and flat fork will be difficult after long-term use There is a gap, so there will be looseness, especially the chain guard is made of elastic material, so the positioning effect is even worse; second, when the motorcycle chain guard is installed, the front end is set on the motorcycle flat fork, and the

tail passes through the set hanging hole Positioning after

hooking with the lugs on the horizontal tube, this positioning method only uses one point positioning, the reliability and stability of positioning are poor, and the motorcycle chain guard is also easy to deform

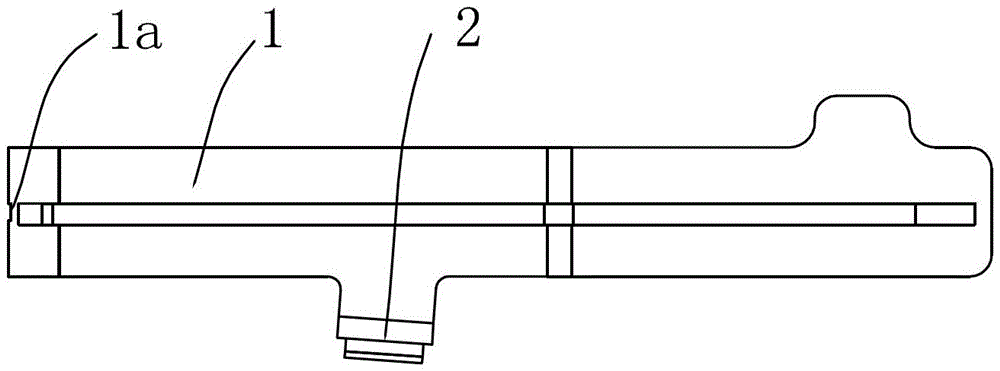

The Chinese invention patent named "Motorcycle Chain Guard and Flat Fork Combination" with patent number 209202069608 discloses a combination of motorcycle chain guard and flat fork. On the top, the rear end is fixed on the fork by bolts. The

disadvantage is that the chain guard is fixed by one-point positioning, and the front end is easy to loosen, thus slipping off the fork. At the same time, the reliability and stability of one-point positioning are poor. At the same time, the chain guard of the motorcycle is also easy to deform; further, the chain guard of the invention adopts the structural form of

tail bolt connection, and the chain guard needs to cross the flat fork horizontal tube to reach the support of the chain guard, so the length of the chain guard is relatively large , which increases the cost of using

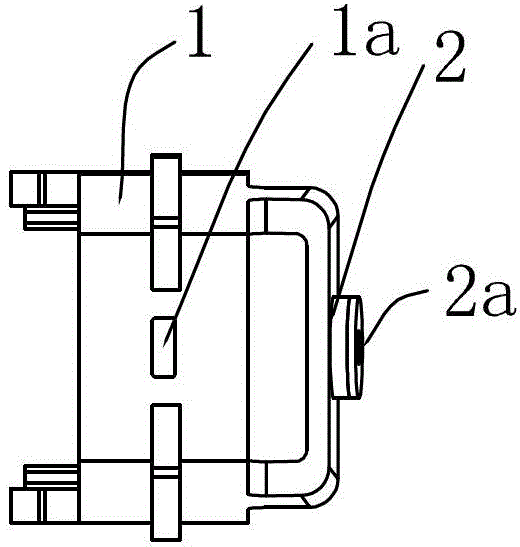

The Chinese invention patent named "Motorcycle Chain Guard and Rear Fork

Assembly" with the patent number of 209202069595 discloses a motorcycle chain guard and rear fork

assembly. On the top, the rear end is fixed with the rear fork by bolts, and the front is positioned by the bump and the tube of the rear fork. The disadvantages are: first, because the bump is

mushroom-shaped, and the diameter of the largest part of the bump head is slightly larger than the tube wall of the rear fork The diameter of the upper via hole, so the bump head and the via hole are an

interference fit, which is difficult to assemble and is easily deformed and scrapped; second, the invention adopts two-point positioning, and there is also the possibility that the front end is easy to loose, thereby slipping off the rear fork, and at the same time The reliability and stability of the two-point positioning are relatively poor; the third is that the chain guard of the invention adopts the structural form of

tail bolt connection, and the chain guard needs to cross the rear fork horizontal tube to reach the chain guard support, so the chain guard The length of the card is relatively large, which increases the cost of use

[0005] In summary, due to the deficiencies in the installation structure of the motorcycle chain guard in the prior art, there will be defects such as poor positioning, assembly deformation, and inability to cooperate well with the chain. Accurate, the guard card installation structure that can effectively shorten the length of the motorcycle chain guard card becomes necessary

Login to View More

Login to View More  Login to View More

Login to View More