Saw bow free from dismounting and displacing and saw blade connecting gripping heads thereof

A disassembly-free and indexing technology is applied in the field of saw bows, which can solve the problems of cumbersome operation and low efficiency, and achieve the effect of convenient use, avoiding disassembly and assembly, and realizing small-angle adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

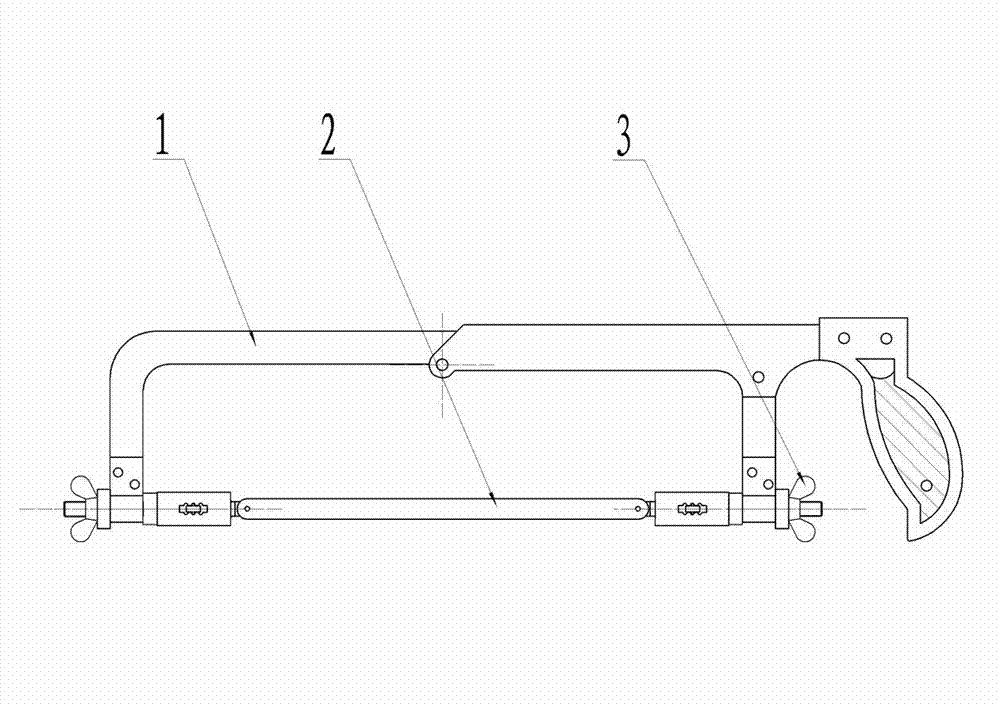

[0029] Embodiments of the present invention exempt from disassembly indexing saw bow: as Figure 1-13 As shown, including the bow frame 1, the left and right ends of the bow frame 1 are respectively equipped with saw blade connecting chucks, and the two saw blade connecting chucks are arranged axially opposite each other. On the saw blade hook pin 8 of head inner end.

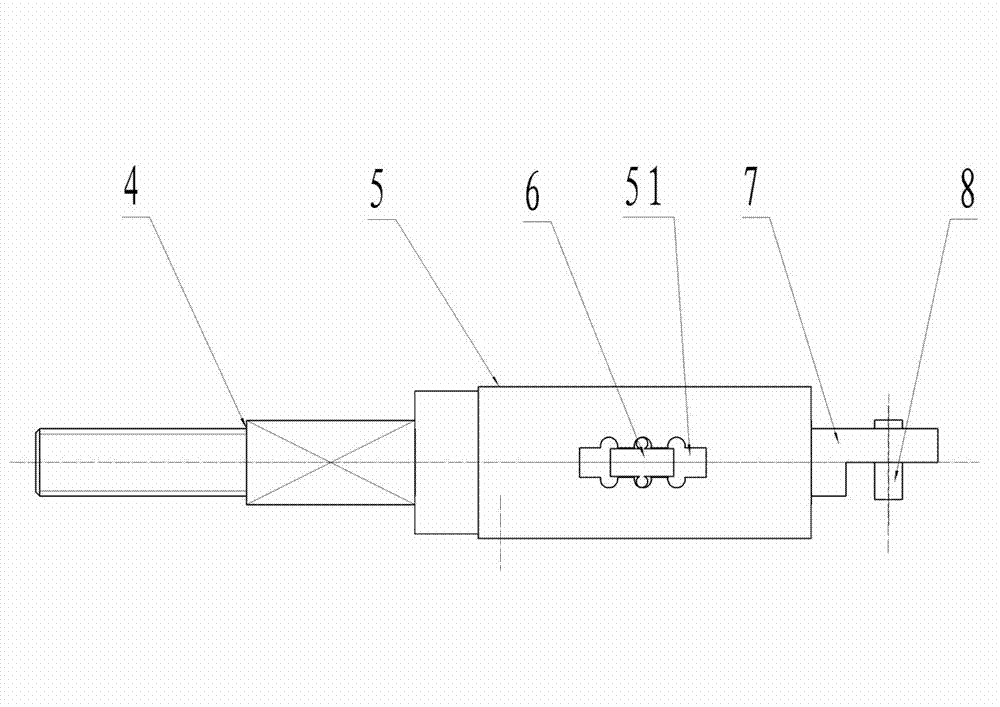

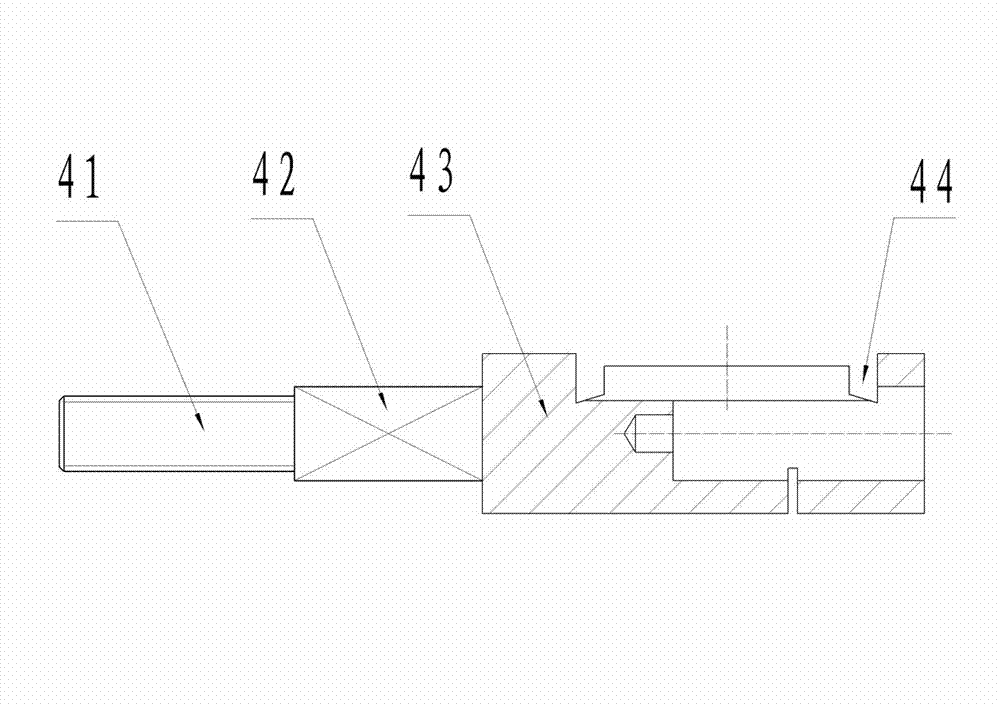

[0030] The saw blade connecting chuck is mainly composed of a chuck body 4, a mandrel 7 and a gear switch mechanism. The structure of chuck body 4 is as image 3 , Figure 4 As shown, it is composed of a screw rod 41, a square tenon 42 and a fixed cylinder 43 that are coaxially connected in sequence from the outside to the inside, wherein the square tenon 42 and the screw rod 41 form the installation section of the chuck body 4, and the square tenon 42 guides the insertion along the left and right directions. Installed on the corresponding end of the bow frame 1, the outer end of the screw rod 41 protrudes f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com