Labyrinth sealing structure and mounting method thereof

A labyrinth seal and labyrinth seal technology, applied in non-variable volume pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve the installation method and installation space limitations, and the sealing effect cannot reach the maximum Good, inconvenient design of filter element compressor, etc., to achieve the effect of good rotor dynamics, simple structure, convenient and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

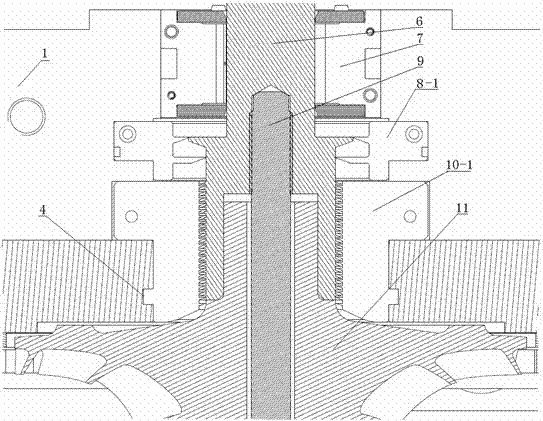

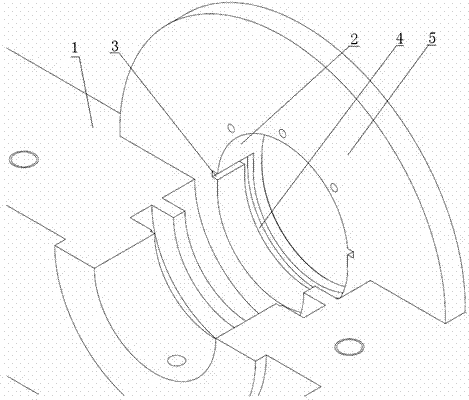

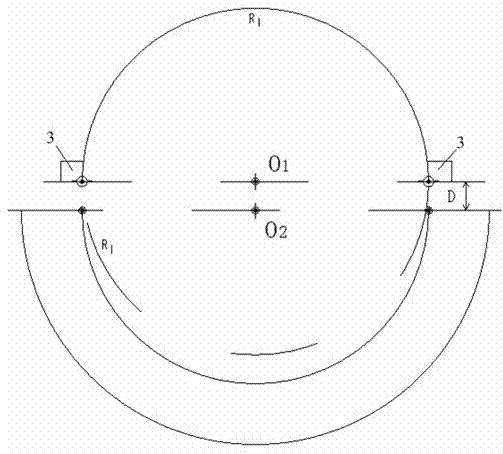

[0029] Such as figure 1 , figure 2 and image 3 As shown, the embodiment of the present invention provides a labyrinth seal structure, including a seal installation hole 2 and a shaft 6 on the gearbox 1, a seal body 10 is arranged in the seal installation hole 2, and the seal body 10 and the shaft 6 form a labyrinth Sealing, an upper oil seal 8-2 and a lower oil seal 8-1 are arranged outside the shaft 6, a pull rod 9 is connected between the shaft 6 and the impeller 11, and a bearing 7 is installed outside the shaft 6. The sealing installation hole 2 is composed of an upper part and a lower part, and the center of the upper section is O 1 and the lower section center O 2 There is a certain distance D between them. The seal instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com