Rotary self-lock pull head

A self-locking and slider technology, applied in the field of zippers, can solve problems such as fragility, unstable safety protection, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

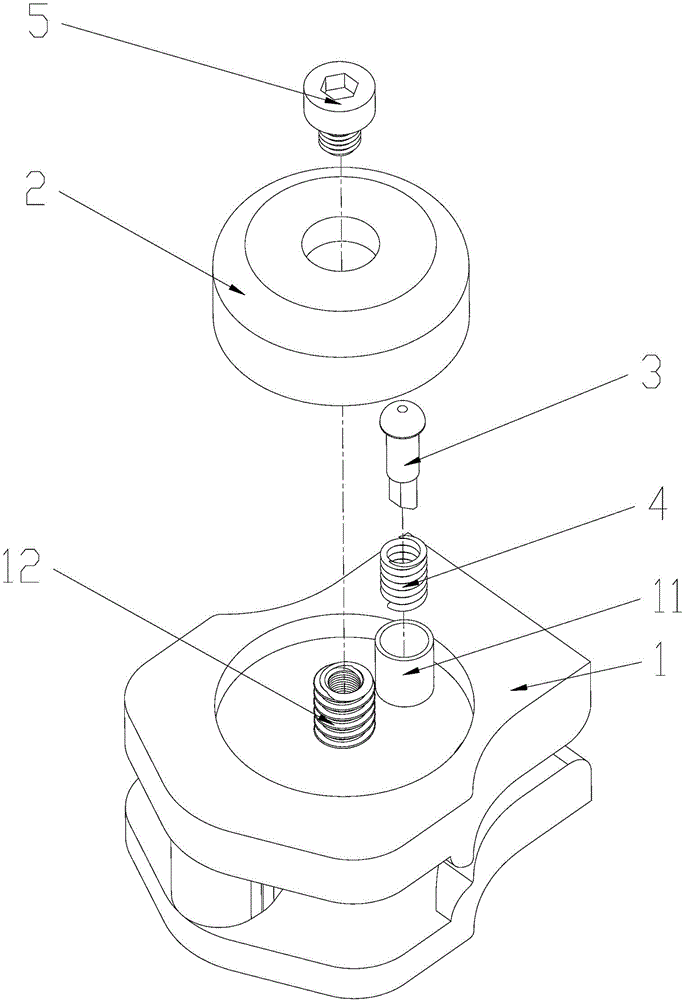

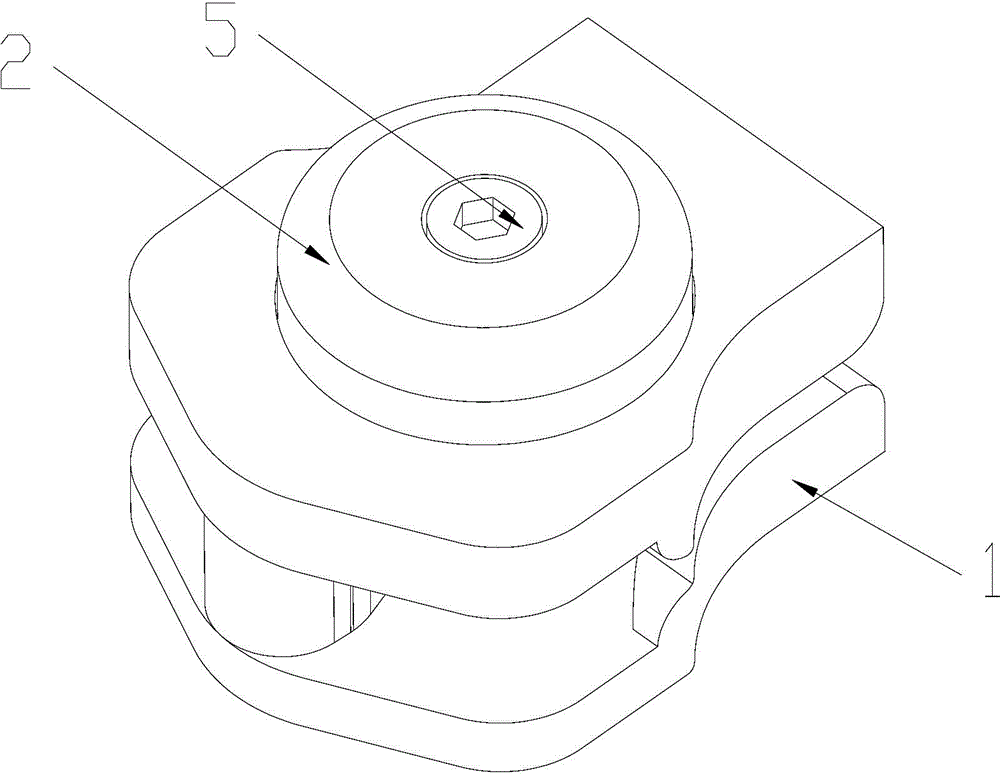

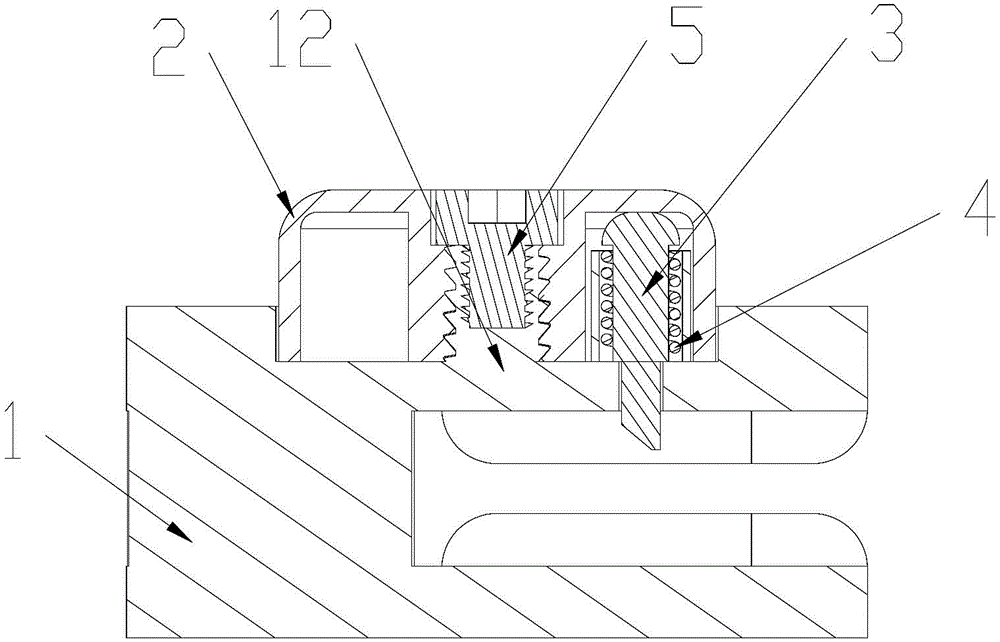

[0027] Example one, such as Figure 1-3 The fixed part shown is a bolt 5 which passes through the through hole on the cap 2 and is directly screwed on the threaded post 12. The abducted bolt head presses the step surface on the through hole of the cap 2 so that the rotating cap cannot be screwed out, so as to lock the cap 2 on the slider body 1.

Embodiment 2

[0028] Example two, such as Figure 7 As shown, the fixing member may also be a rivet 5 which passes through the through hole on the cap 2 and is directly embedded in the threaded column 12. The abducted rivet head presses the step surface on the through hole of the cap 2 so that the rotating cap cannot be screwed out, so as to lock the cap 2 on the slider body 1.

[0029] 2. Directly fixed by threaded column:

Embodiment 3

[0030] Example three, such as Figure 4-6 As shown, the present invention can also directly form a rivet head 121 that restricts the cap 2 from coming out on the top of the threaded post 12 of the upper cap 2 by screwing. The abducted rivet head buckles the step surface on the through hole of the cap 2 so that the rotating cap cannot be unscrewed to lock the cap 2 on the slider body 1.

[0031] Because the spring 4 is squeezed by the upright horse hook 3, there is always an upward force. Combined with the working principle of the thread, the rotating cap 2 rotates upwards or downwards to move the upright horse hook 3 up and down to realize unlocking and self-locking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com