Recyclable impact-resistant multi-stage yielding device and method

A technology of impact resistance and ejection device, which is used in earth-moving drilling, installation of bolts, mining equipment, etc., can solve problems such as roof caving, bolt breakage, inability to consume deformation energy, etc., and achieve the effect of strong bearing capacity and danger prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

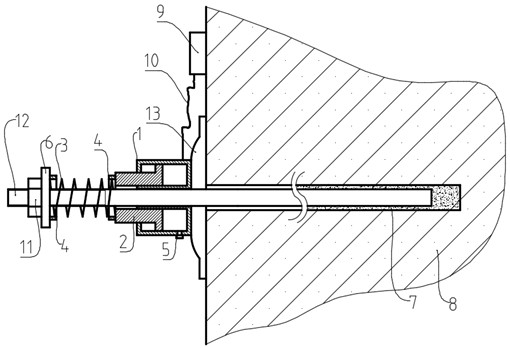

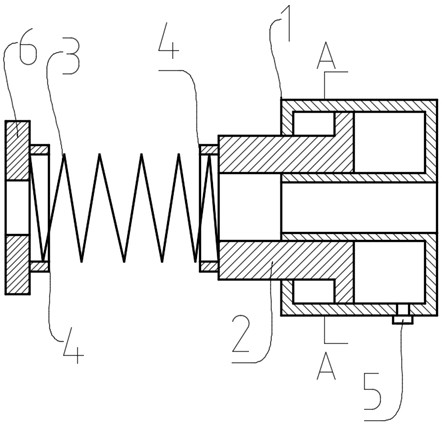

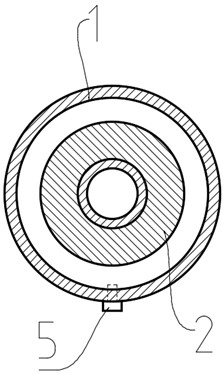

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] see Figure 1-3 As shown, an embodiment of a recyclable impact-resistant multi-stage pressure relief device includes: a slow-release resistance-increasing component, the slow-release resistance-increasing part includes a tray 13, and a through hole is opened in the center of the tray 13, and the tray 13 The diameter of the central circular hole is slightly larger than the diameter of the anchor rod 12, which is convenient for the anchor rod 12 to pass through. The tray 13 is connected with a cylinder 1, the cross section of the cylinder 1 is a ring structure, the cylinder 1 is provided with a pressure relief valve 5, the cylinder 1 is filled with compressible gas as a resistance increasing medium, and the cylinder 1 is provided with a piston 2, The compressible gas is used to provide resistance when the anchor rod 12 slides away from the drilling hole during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com