Integrated heat dissipation structure for power electronic device and assembly method thereof

A technology of power electronic devices and heat dissipation structures, which is applied in the direction of circuit heating devices, electric solid state devices, semiconductor devices, etc., can solve the problems of complex assembly and high cost of heat dissipation structures, and achieve the effect of simple structure, less equipment investment, and less assembly parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

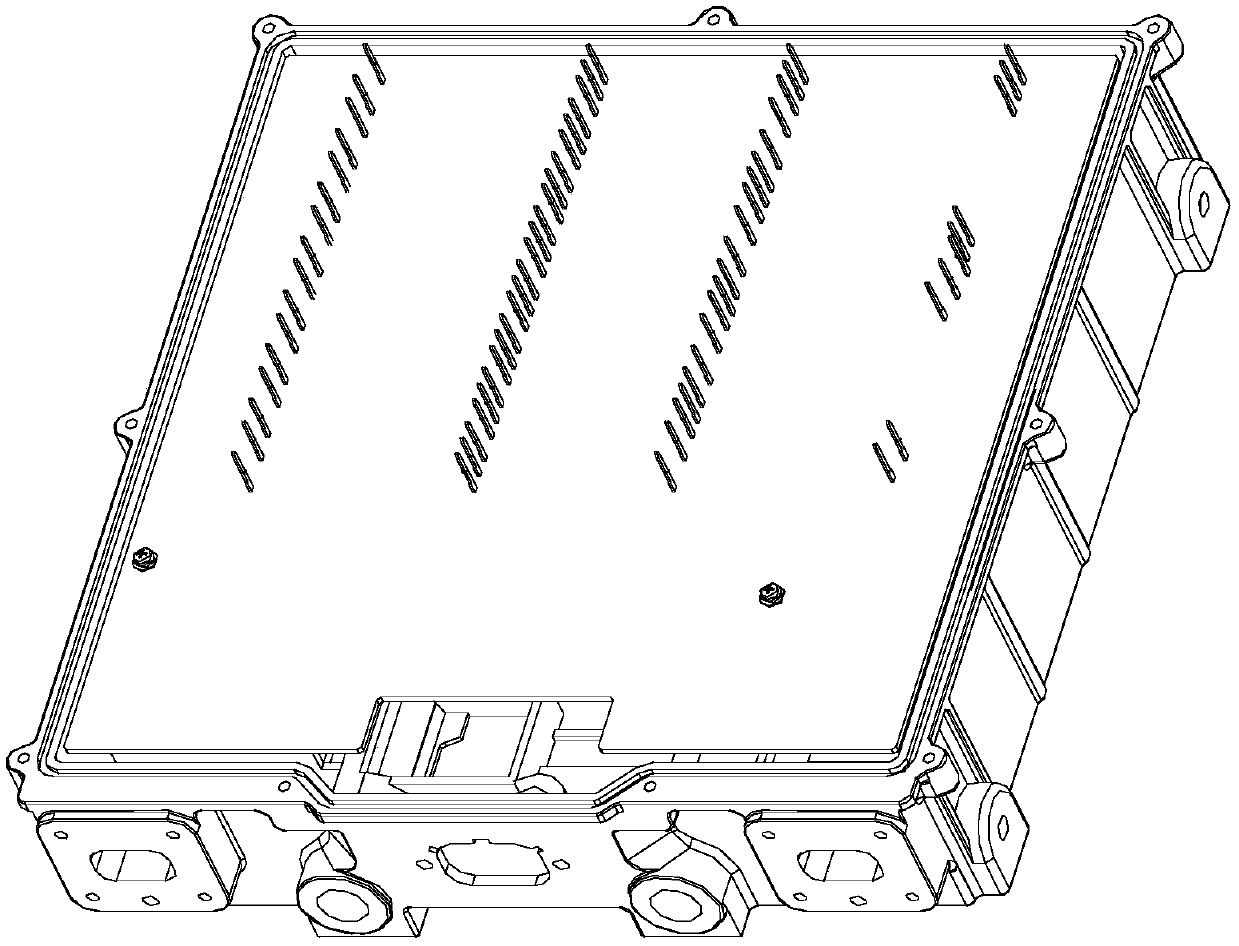

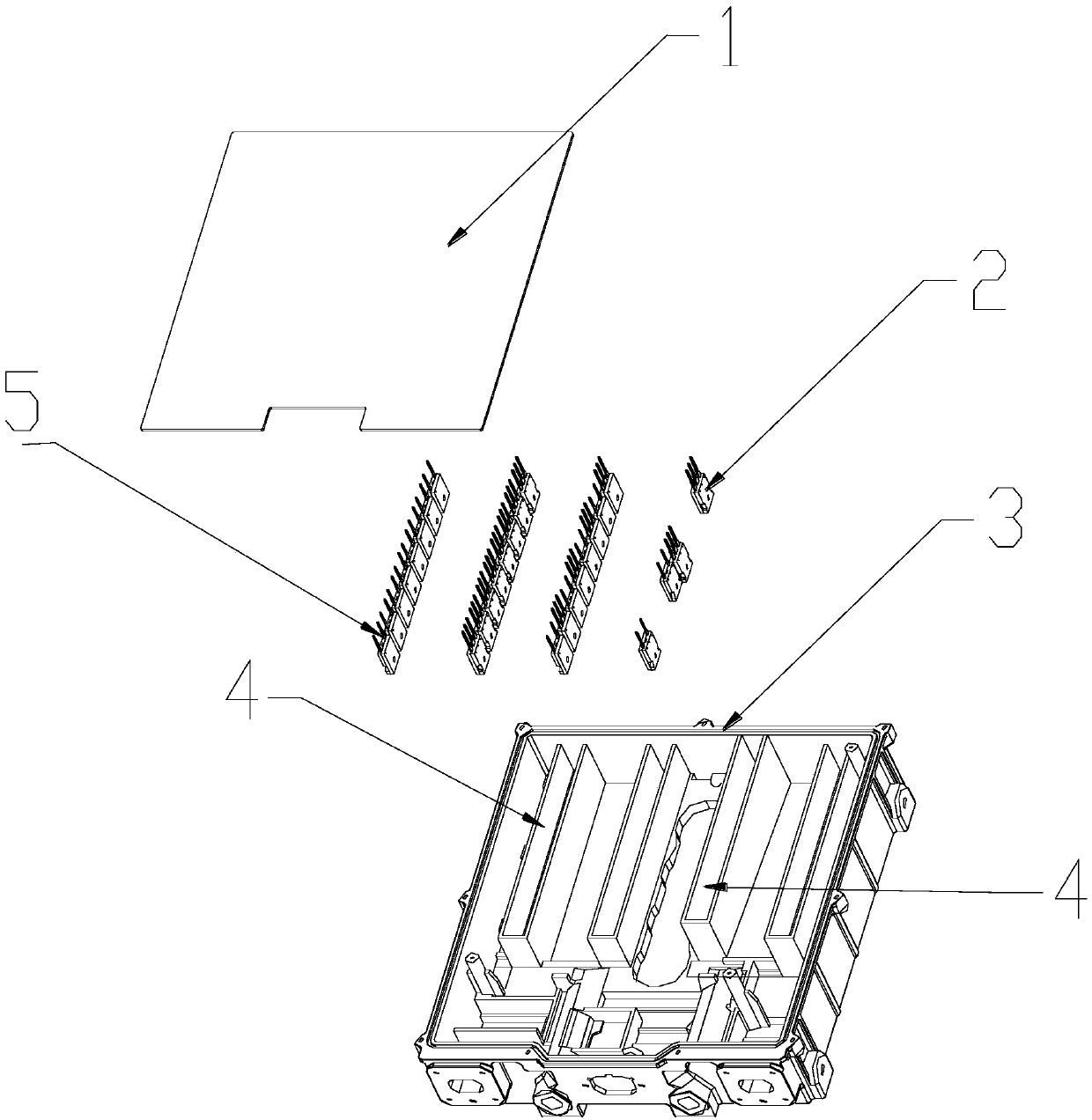

[0016] According to one or more embodiments, such as figure 1 and figure 2 As shown, the heat dissipation structure of an integrated power electronic device includes a circuit board to be assembled 1, a device MOSFET 2, a metal main shell 3, a high thermal conductivity insulating glue 4, and a device MOSFET 5.

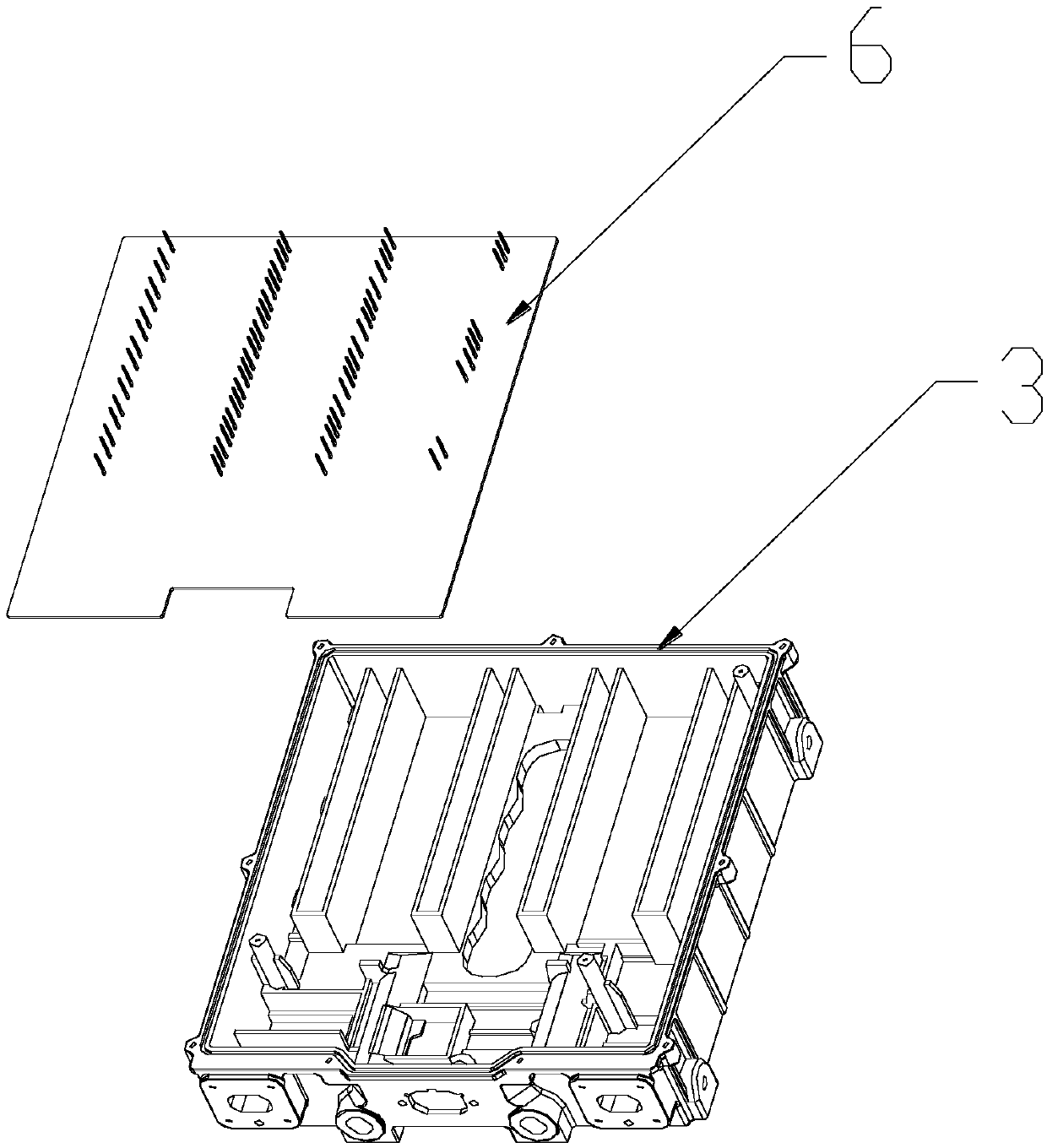

[0017] According to one or more embodiments, such as image 3 As shown, it is a schematic diagram of an assembly state of an integrated heat dissipation structure of a power electronic device. In the production process of the circuit board company, firstly, the components after welding the circuit board 1 and the device MOSFET 2 and device MOSFET 5 are shipped to the assembly factory; The coefficient insulating glue 4 is potted into the sealed cavity in the metal shell 3 after the dosage is determined. Then if image 3 As shown, the assembled circuit board assembly 6 is assembled with the metal main casing 3 . At this time, the sealed cavity of the metal main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com