A power lowering type tower pumping unit

A tower pumping unit and power release technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of inconvenient unloading, inconvenient maintenance, and large reversing impact, and reduce production costs. , The effect of giving way is convenient and the friction force is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

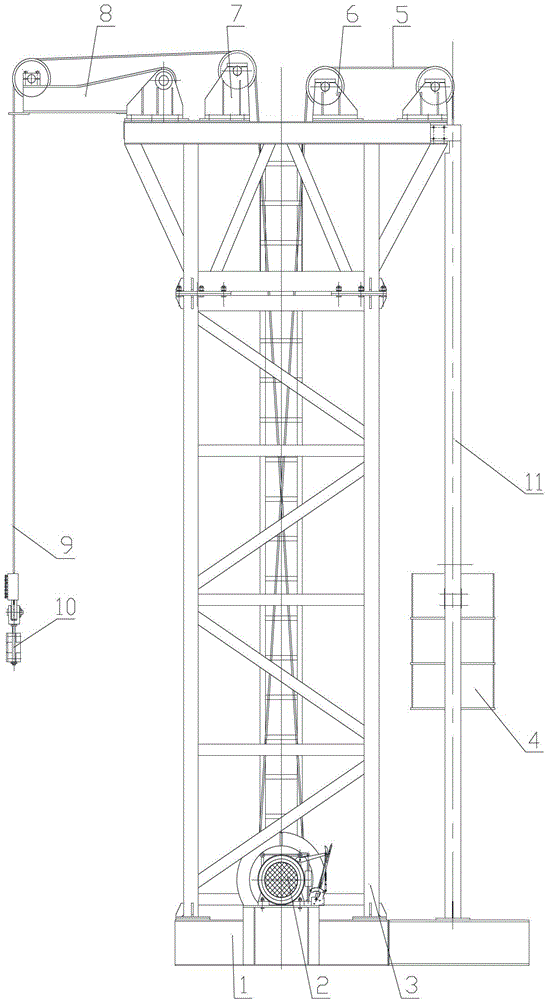

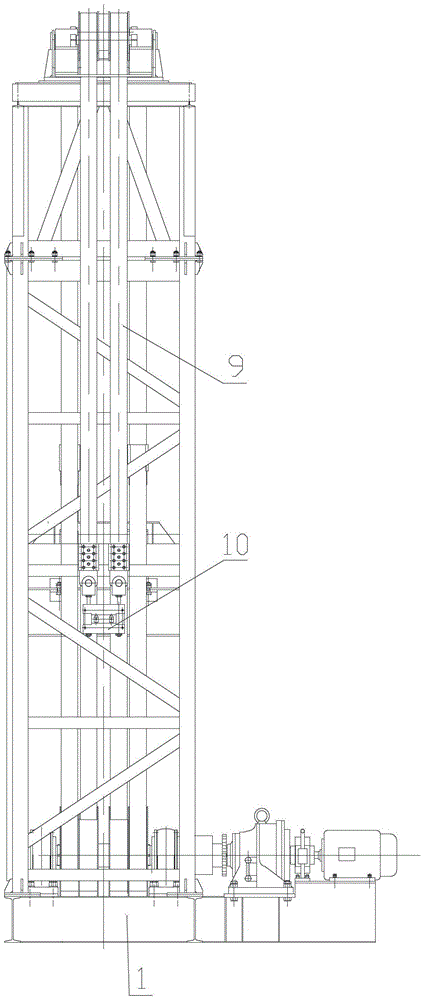

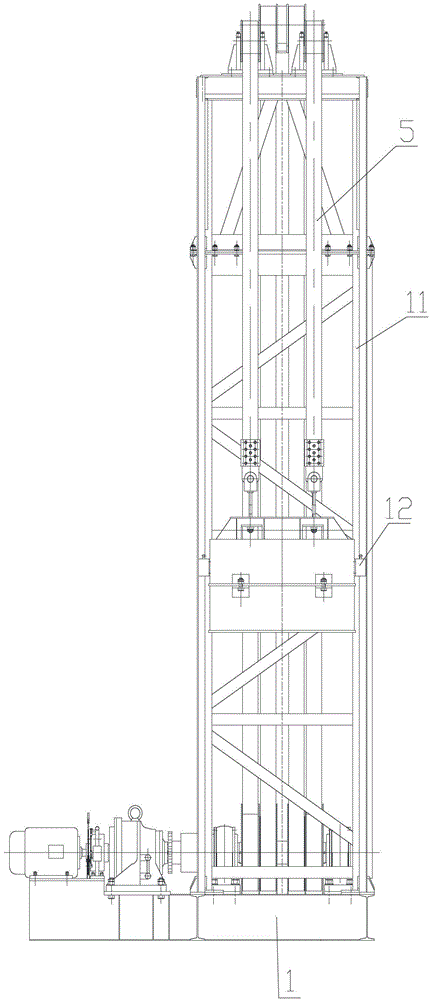

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0052] combine Figure 1-Figure 3 , The power lowering tower pumping unit of this preferred embodiment includes a base 1, a tower 3, a power system 2 connected to the base 1, a front sling traction system and a rear sling traction system. The tower 3 is a combined structure, which is connected by multiple tower sections, and the tower section can be increased or decreased according to site requirements to raise or lower the height of the tower; or the tower is set as an integral structure, and the frame is an integral In the structure, there is no need to disassemble and assemble, which simplifies the construction procedure and is suitable for low tower occasions.

[0053] Among them, such as Figure 4 , the power system 2 includes a sequentially connected motor 13, a planetary cycloid reducer 17 and a reel 21; the input end of the motor 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com