Manufacture method for standardized fire fighting pipe fitting

A production method and technology for fire protection pipes, which are applied in the directions of pipes/pipe joints/pipe fittings, through components, sleeves/socket connections, etc., can solve the problems of low installation efficiency, long construction period and high cost, and ensure product quality and save money. time, and the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

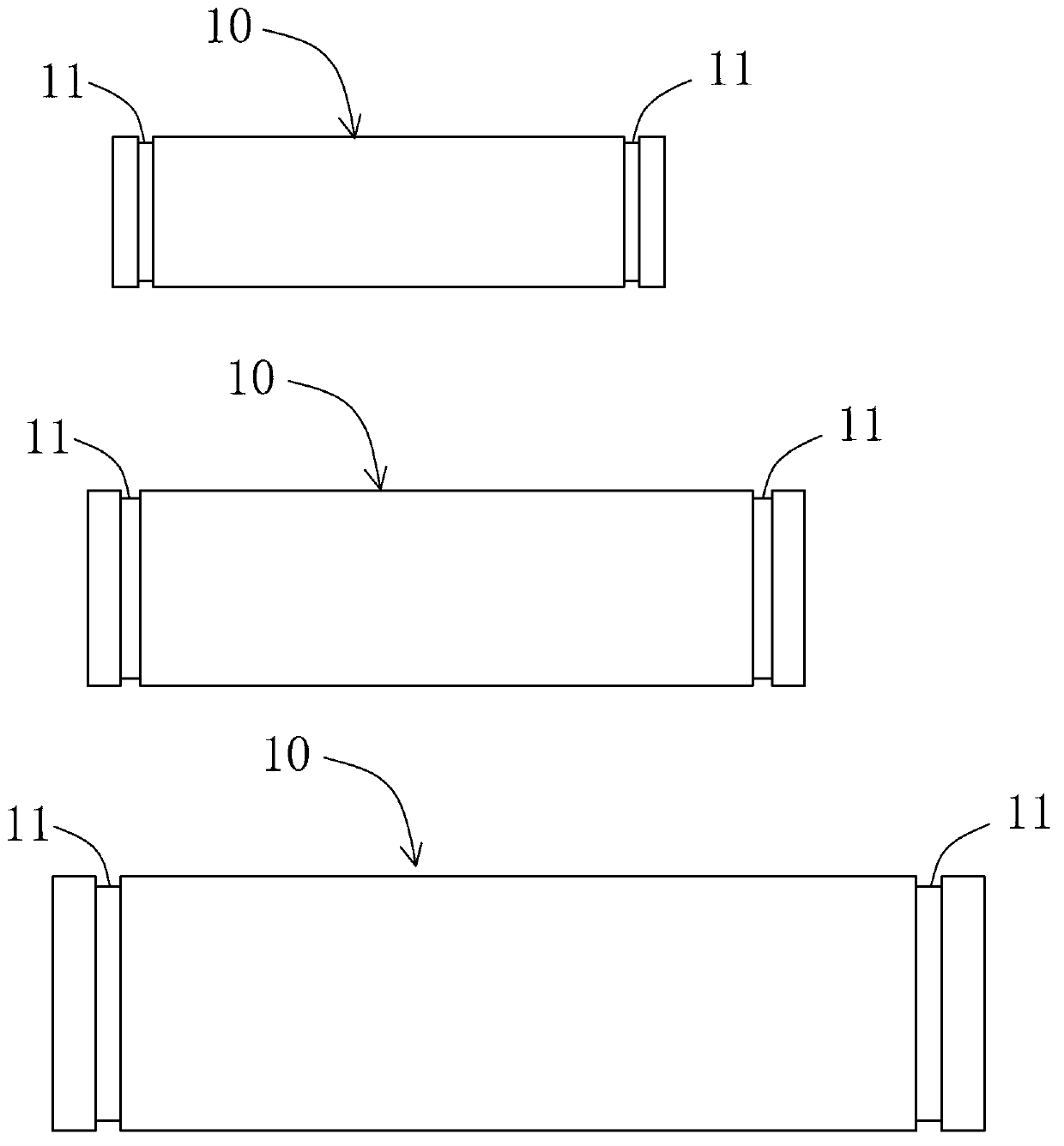

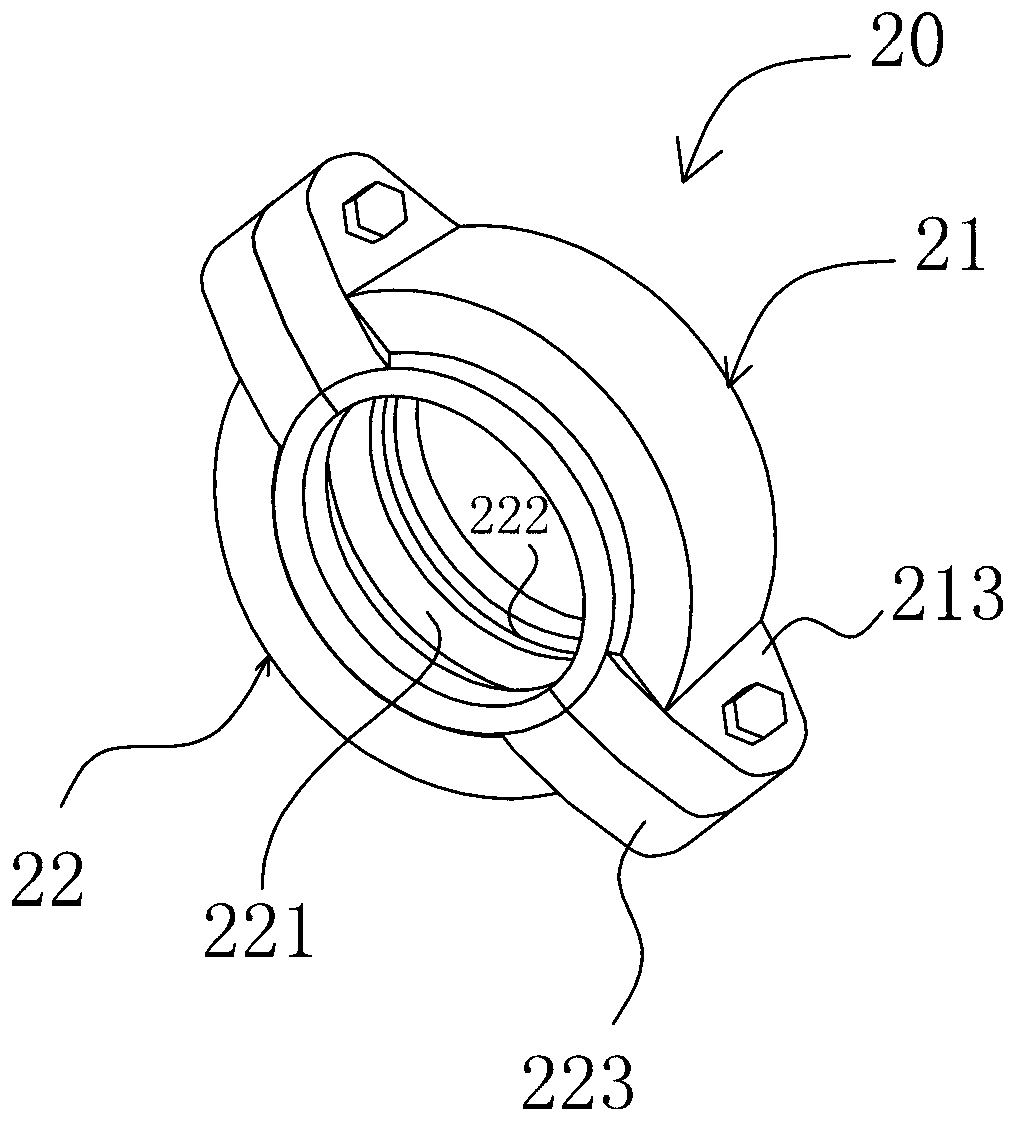

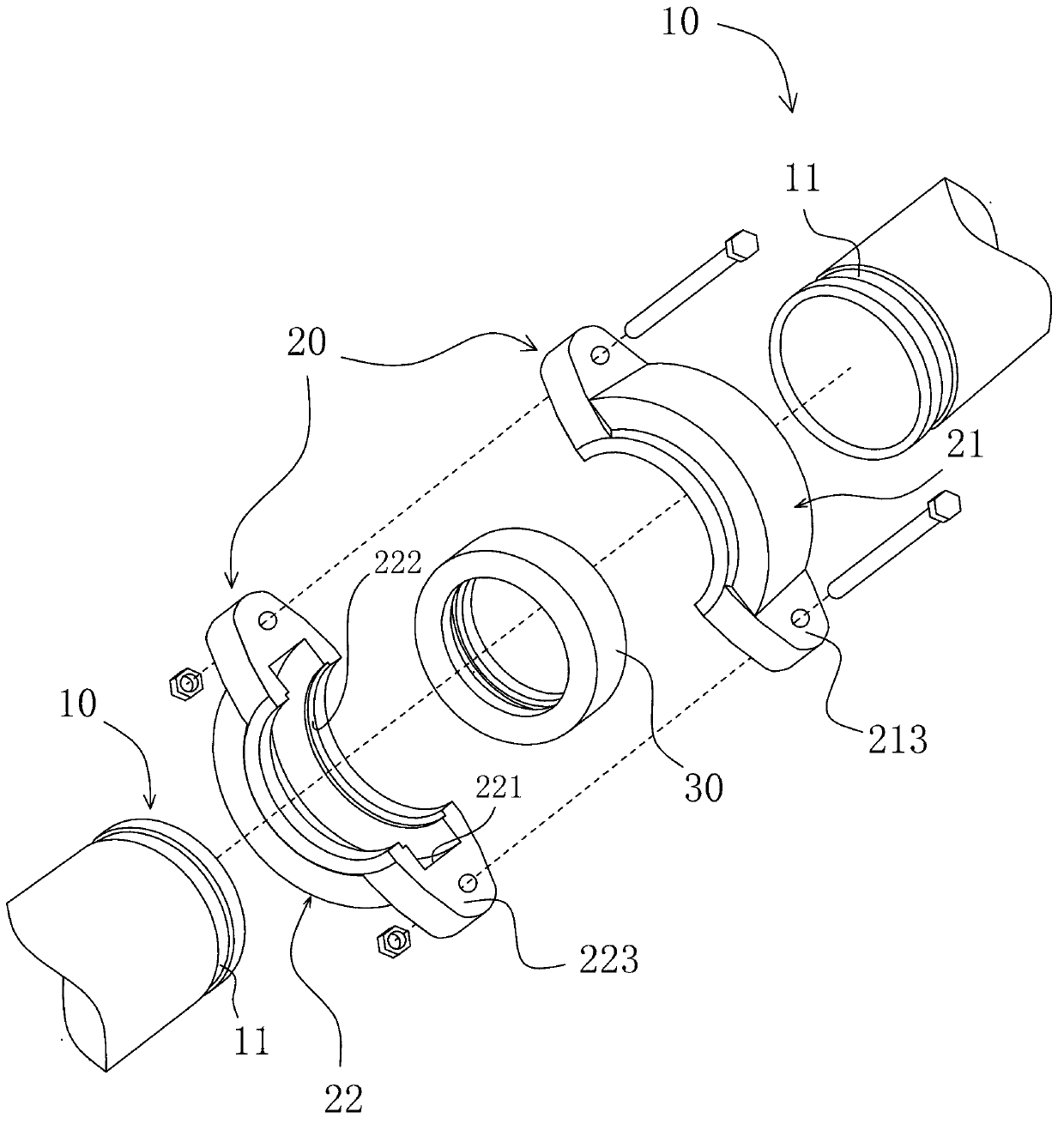

[0016] The manufacturing method of the fire-fighting pipe fittings of the present invention is a method for mass-producing fire-fighting pipe fittings of various specifications. The fire-fighting pipe fittings are pipe fittings connecting indoor fire hydrants and indoor water supply pipes. In different buildings, according to different floors, users, etc., the diameter and length of the fire-fighting pipe fittings are designed to be different. Therefore, it is necessary to produce fire-fighting pipe fittings of different specifications to meet actual needs.

[0017] In this embodiment, steel pipes of different diameters are taken, which can be seamless steel pipes or seamed steel pipes, and the steel pipes are cut into pipes of different sizes, for example, steel pipes of different diameters can be cut into pipes w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com