MEMS bistable optical switch and method of use thereof

一种光学开关、双稳态的技术,应用在MEMS光学开关领域,能够解决镜尺寸深度小、制造成本高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following Detailed Description describes the current best contemplated mode of carrying out the teachings. The description should not be read in a limiting sense, but is presented merely as an illustration of the general principles of these teachings, since the scope of these teachings is best defined by the appended claims.

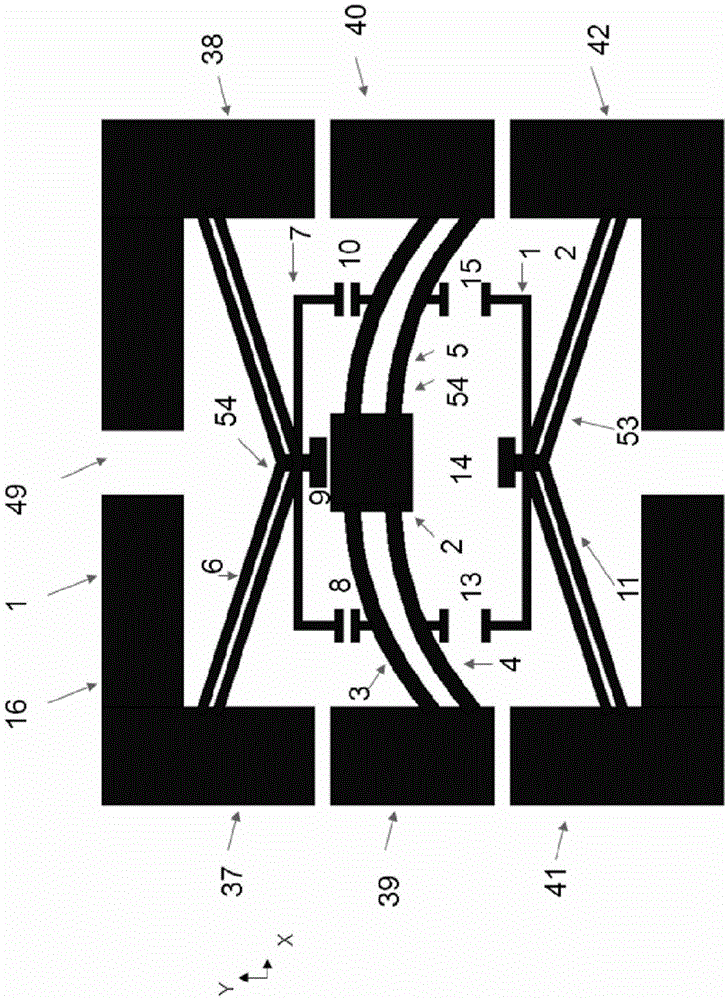

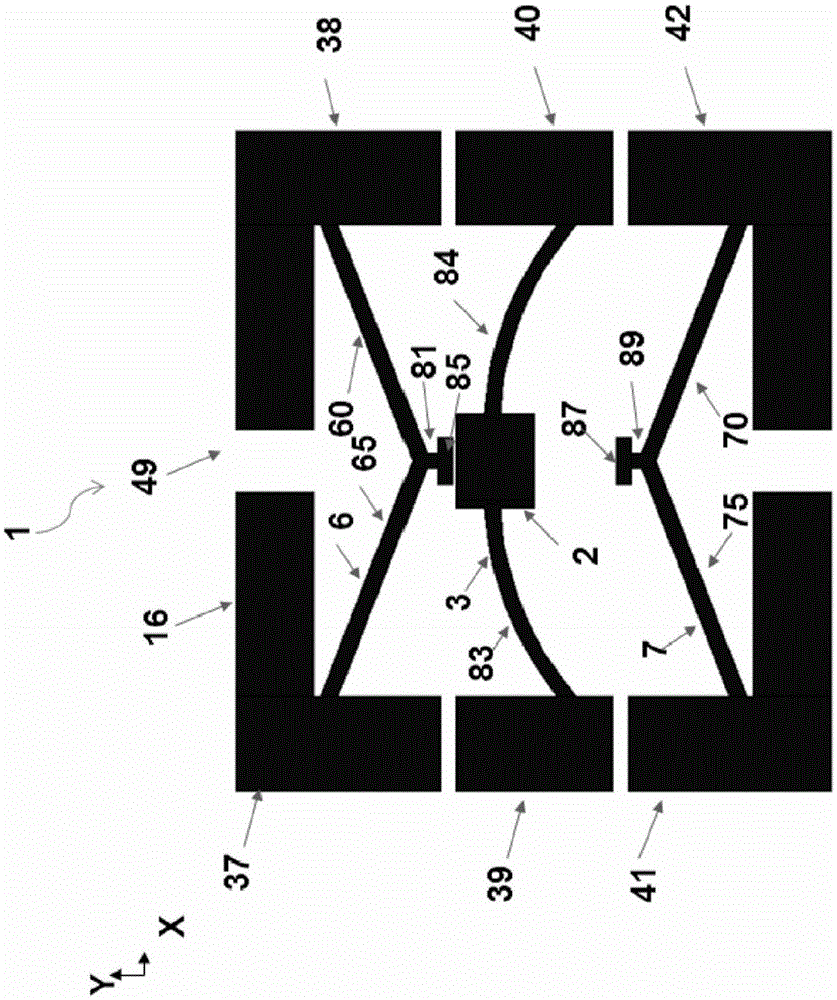

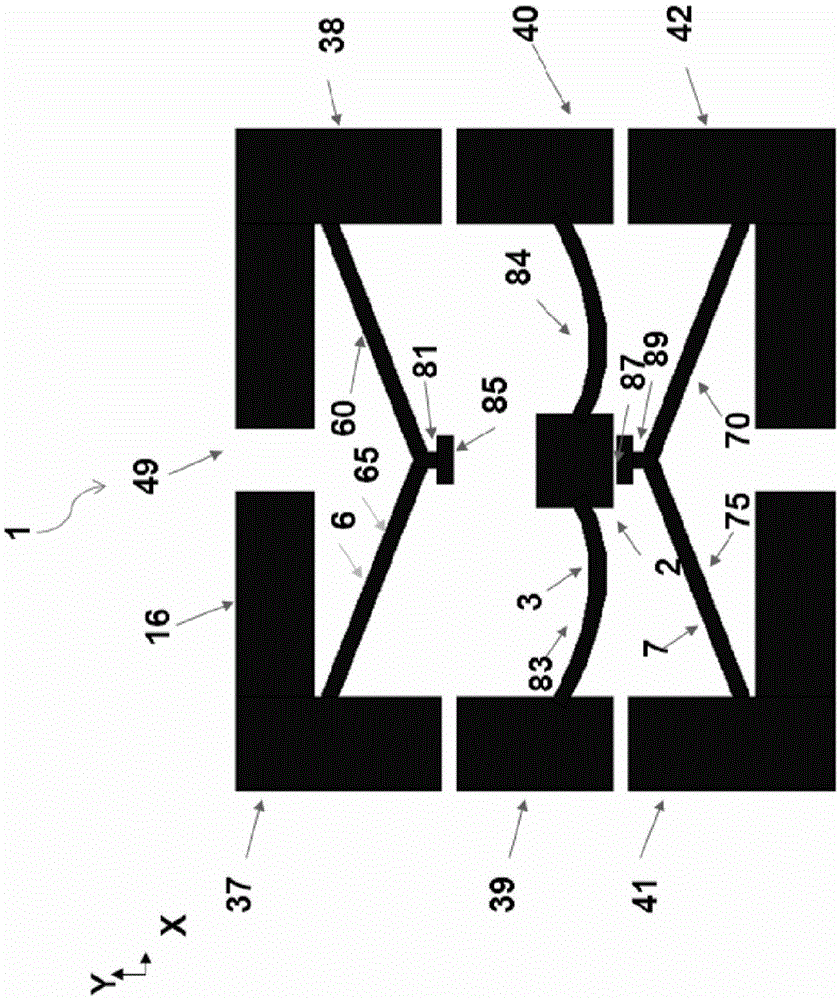

[0016] In one embodiment, the present teachings overcome the above problems by providing an optical switch that uses one or more elements of a microelectromechanical systems (MEMS) device aligned with one or more fiber optic collimators to direct light beams from one or more input ports to one or more output ports. In that embodiment, the MEMS chip has an in-plane optical reflective component (such as but not limited to a mirror) and two electrothermal actuator components suspended on a self-latching bistable mechanism. The actuator drives the bistable mechanism from its first stable position to its second stable position and from its second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com