Double-support type steel straightener and quickly-replaceable roller set thereof

A straightening machine and double support technology, applied in the field of steel rolling machinery, can solve the problems affecting the normal production rhythm of enterprises, affecting the development of the national economy, and the existence of potential safety hazards, so as to reduce processing and manufacturing costs and operating costs, light weight of equipment, and products good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

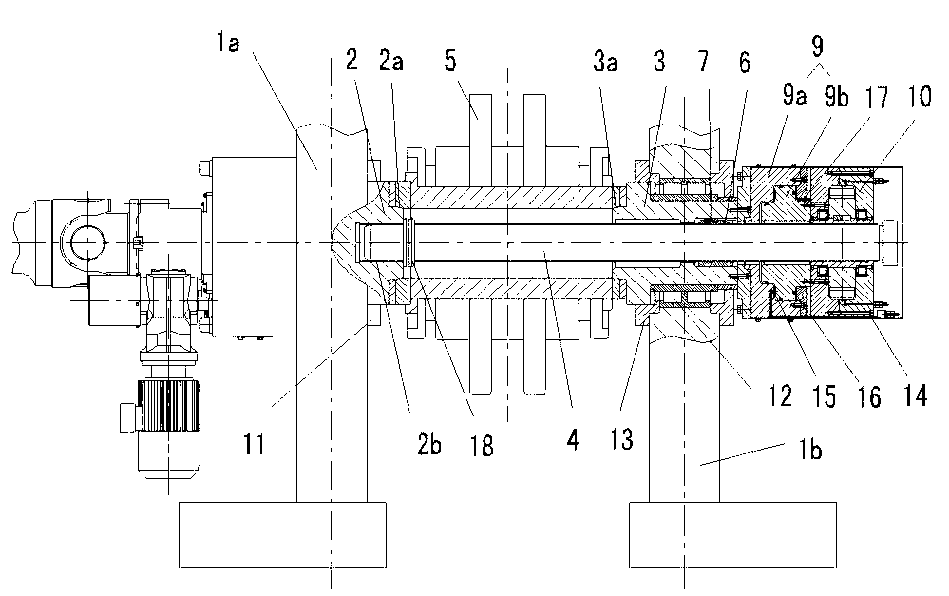

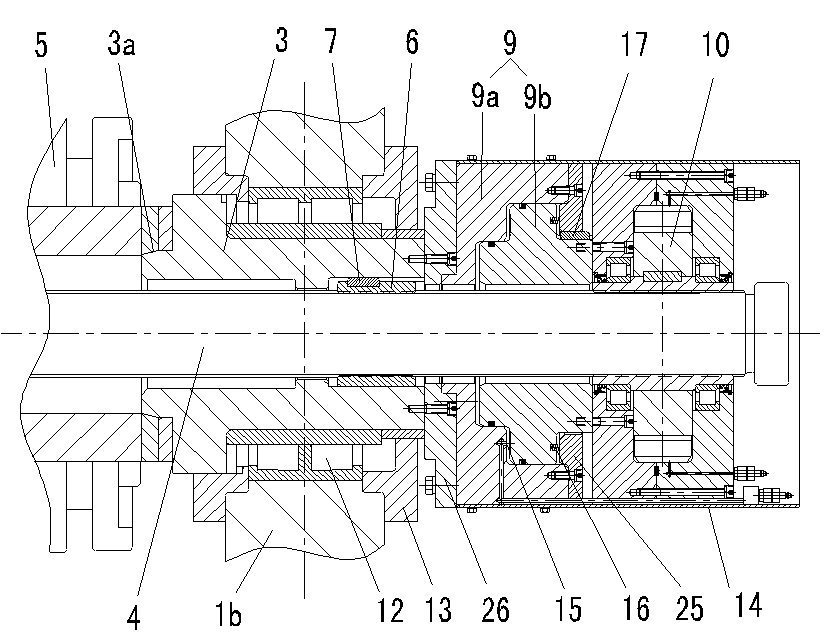

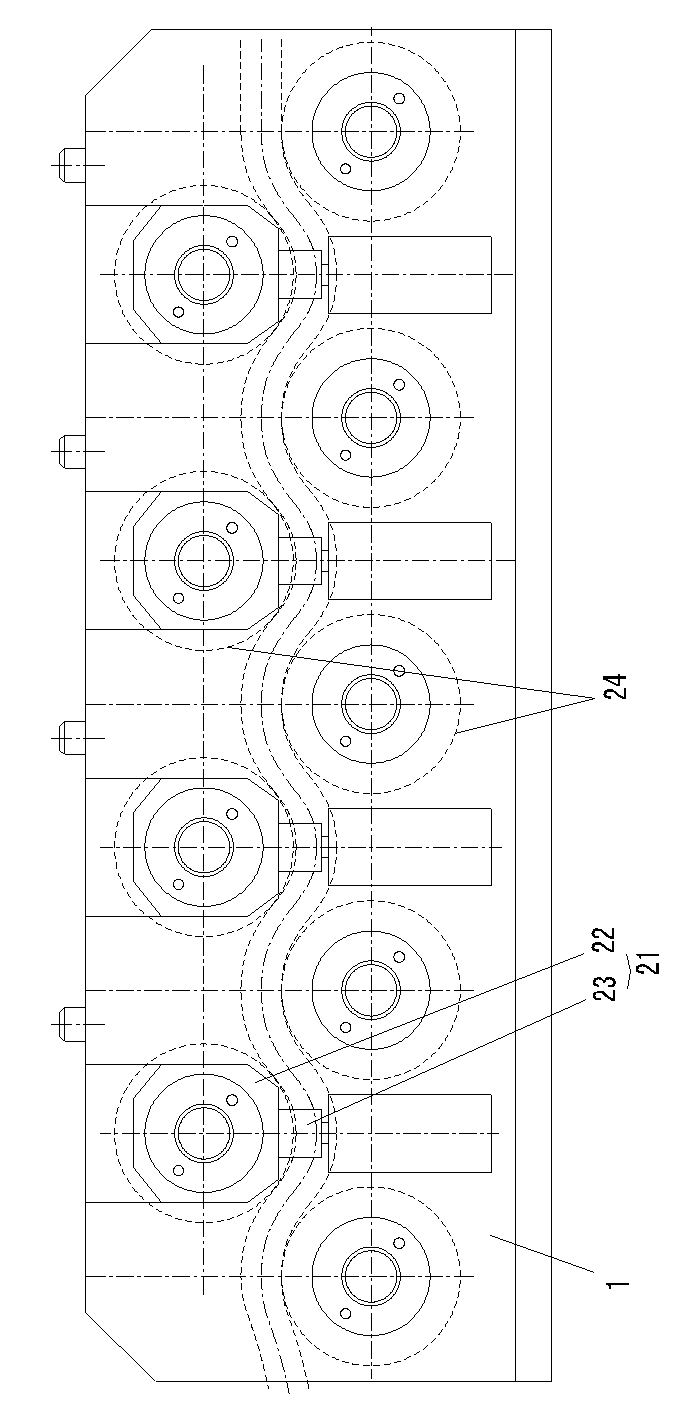

[0046] Such as figure 1As shown in the figure, it is a structural schematic diagram of an embodiment of the double-supported steel straightening machine of the present invention for quickly replacing the roller set. The quick-change roller set of the double-supported steel straightening machine in this embodiment includes a transmission shaft 2 , a driven shaft 3 , a straightening roller 5 , a locking mechanism 8 and an axial adjustment device 20 . The transmission shaft 2 is mounted on the transmission side frame 1a of the straightener with rotation fit, and the driven shaft 3 is mounted on the operation side frame 1b of the straightener with rotation fit, and the opposite end of the transmission shaft 2 and the driven shaft 3 is provided with a The guide structure for clamping and straightening roller 5. The two sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com