Straight push type steel dam

A direct-push, steel dam technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems that hinder the application and promotion of steel dam gates, high requirements and difficulties in construction and installation, and high manufacturing costs of steel dam gates. To achieve the effect of reasonable force, simplified structure, safe and reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

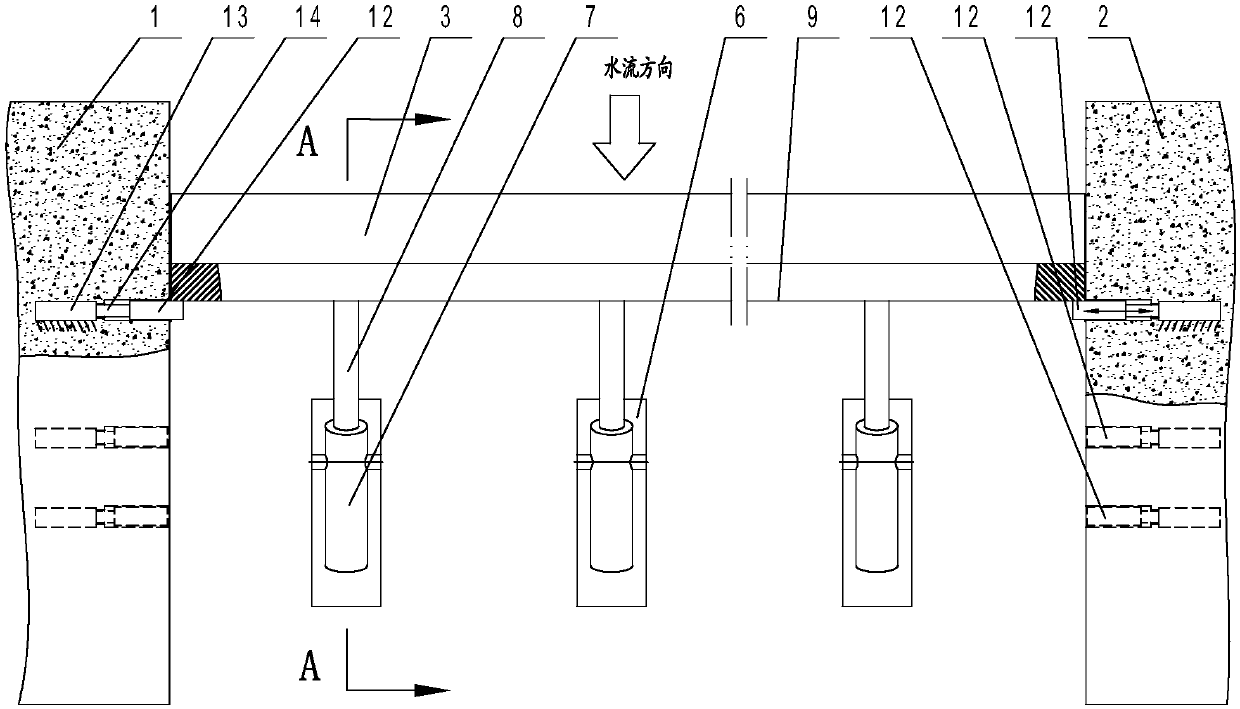

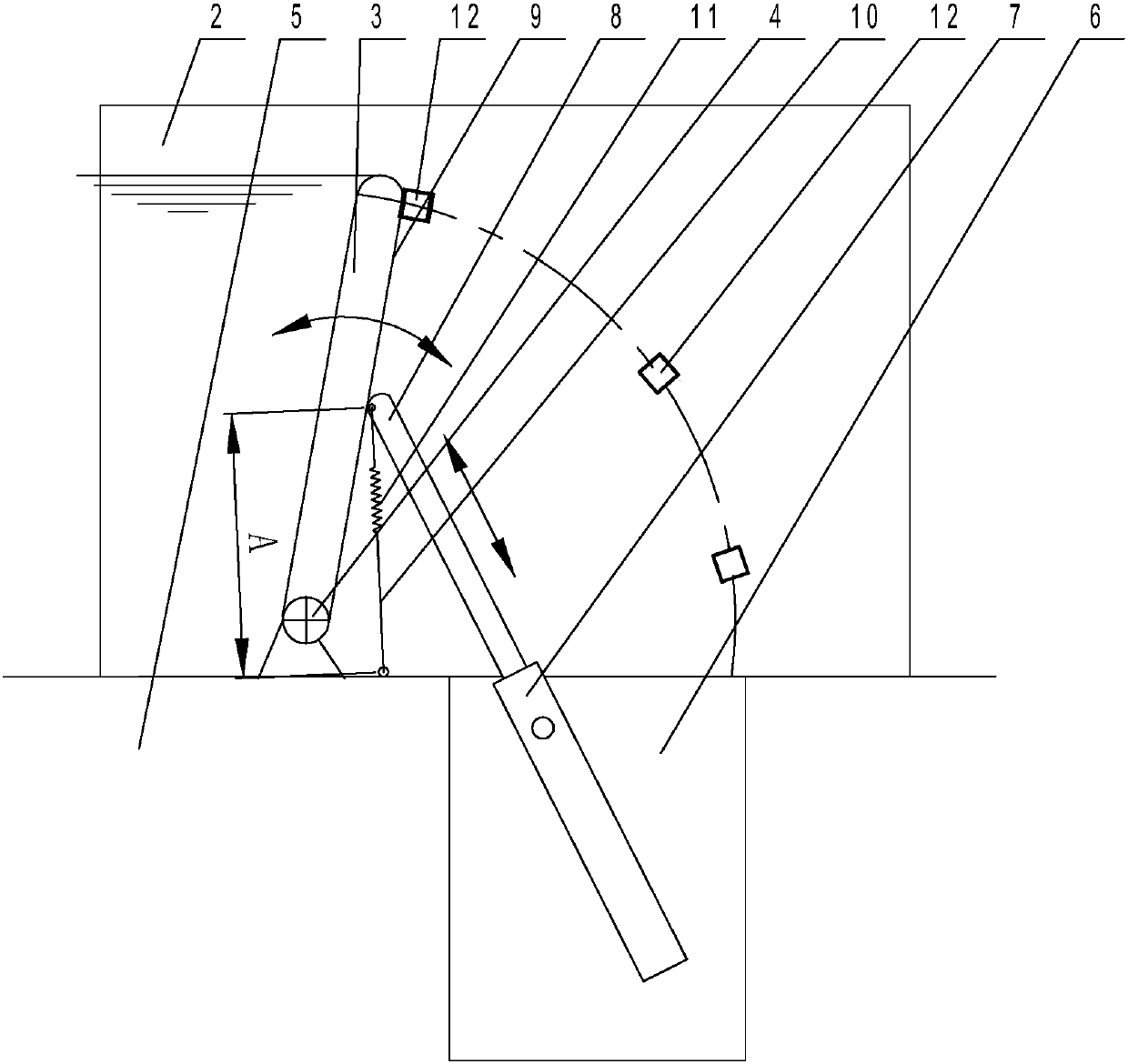

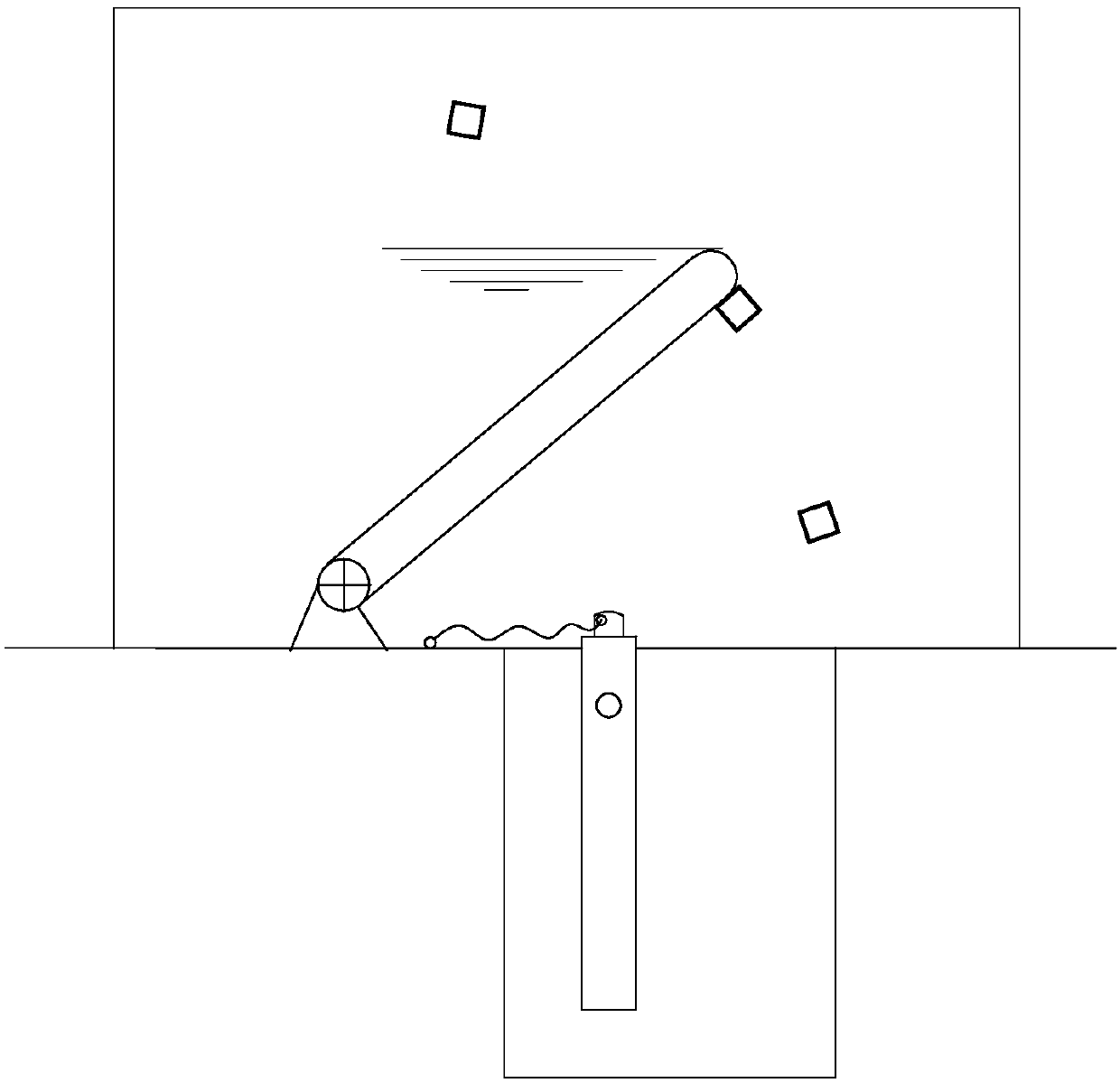

[0023] figure 1 , figure 2 It is a schematic diagram of a direct-push steel dam structure. It can be seen from the figure that it includes a steel dam door leaf 3 installed between the left wall 1 and the right side wall 2, and the bottom of the steel dam door leaf 3 is connected with the dam body 5 through the bottom horizontal shaft 4, and the steel dam door The leaf 3 swings around the bottom horizontal axis 4, and when the steel dam door leaf 3 swings up, it can block water, and when it swings down, it can discharge water. On the dam body 5 on the back surface of the steel dam door leaf 3, a plurality of pits 6 are formed in rows, and a lifting cylinder 7 is installed in the pit 6, and the front end of the piston rod 8 in the lifting cylinder 7 withstands the steel dam door leaf 3 The back 9 of the steel dam door leaf 3 is pushed up or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com