Negative pressure square cabin clinical check module

A technology of clinical testing and negative pressure formula, which is applied in the field of negative pressure shelter clinical testing modules, can solve the problems of not having negative pressure function, not having the function of infectious disease inspection and treatment, and not having the function of stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

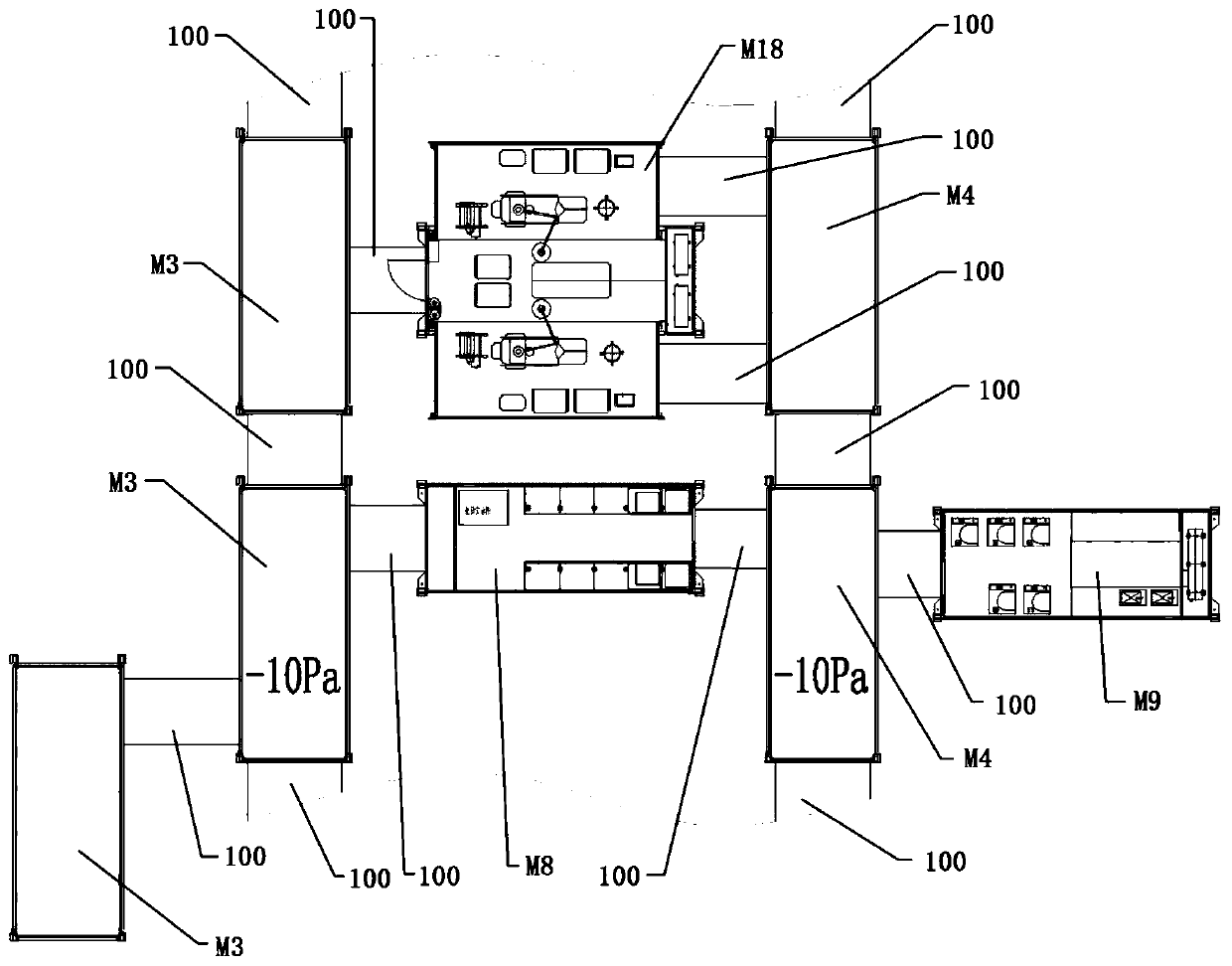

[0033] refer to Figure 1 to Figure 10 As shown, a negative pressure shelter clinical testing module includes a clinical testing unit M8, a disinfection and sterilization unit M9, and an operating unit M18. The improvement is that both the clinical testing unit M8 and the operating unit M18 pass through The channel device 100 is connected to the medical channel unit M3, and the other side is connected to the patient channel unit M4 through the channel device 100, and the other side of the patient channel unit M4 is connected to the disinfection and sterilization unit M9 through the channel device 100, The medical access unit M3 and the patient access unit M4 are connected through the channel device 100, and the negative pressure cabin body 2 is connected to the sides of the clinical examination unit M8, disinfection and sterilization unit M9 and operation unit M18; The air supply filtration efficiency of the negative pressure cabin 2 is ≥99.9%@0.3μm, the exhaust air filtration...

Embodiment 2

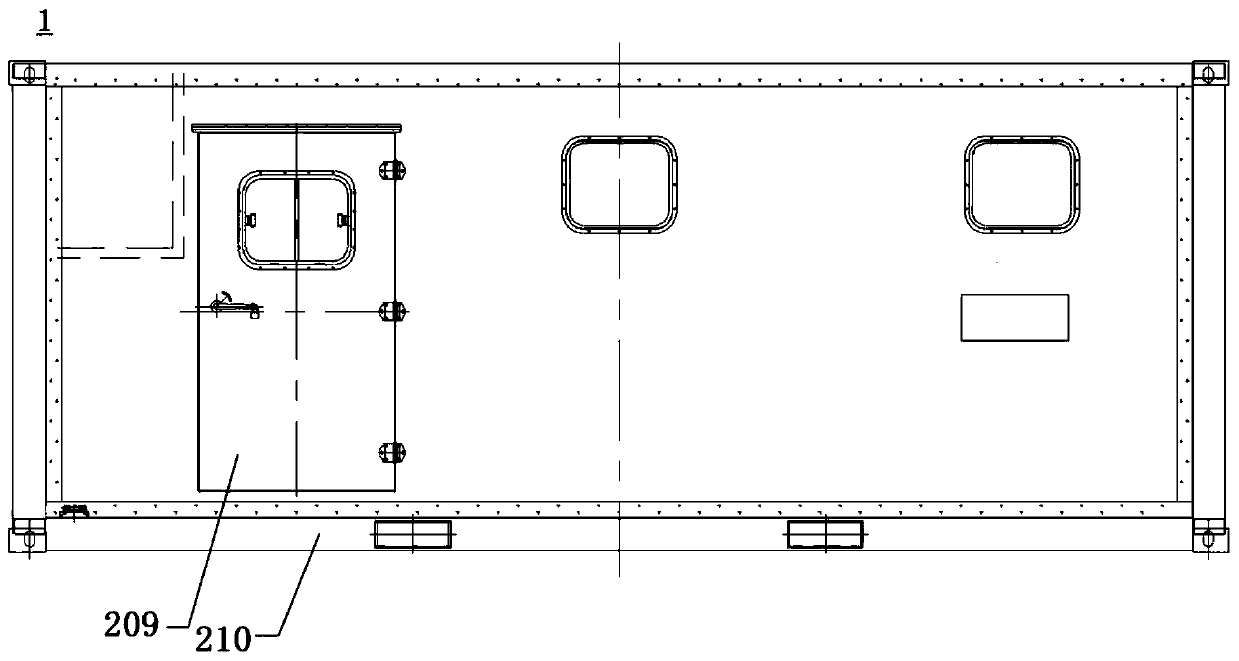

[0036] On the basis of embodiment 1, with reference to figure 2 , 3 As shown, at least one side of the shelter body 1 of the clinical inspection unit M8 is provided with a sealed hatch 209, and the sealed hatch 209 realizes the opening and sealing of the shelter body 1 through the door handle and the locking structure linked with the door handle. Close; the bottom of the shelter body 1 is provided with a chassis 210, and the clamping column located at the bottom of the shelter body 1 cooperates with the draw-in groove located at the top of the chassis 210 to realize the clamping and fixing of the shelter body 1 and the chassis 210.

[0037] Further, the side wall and / or the top wall of the shelter body 1 of the clinical testing unit M8 is provided with lighting windows.

[0038] Further, the airtight hatch 209 is also provided with a fire extinguisher and a monitoring display screen.

Embodiment 3

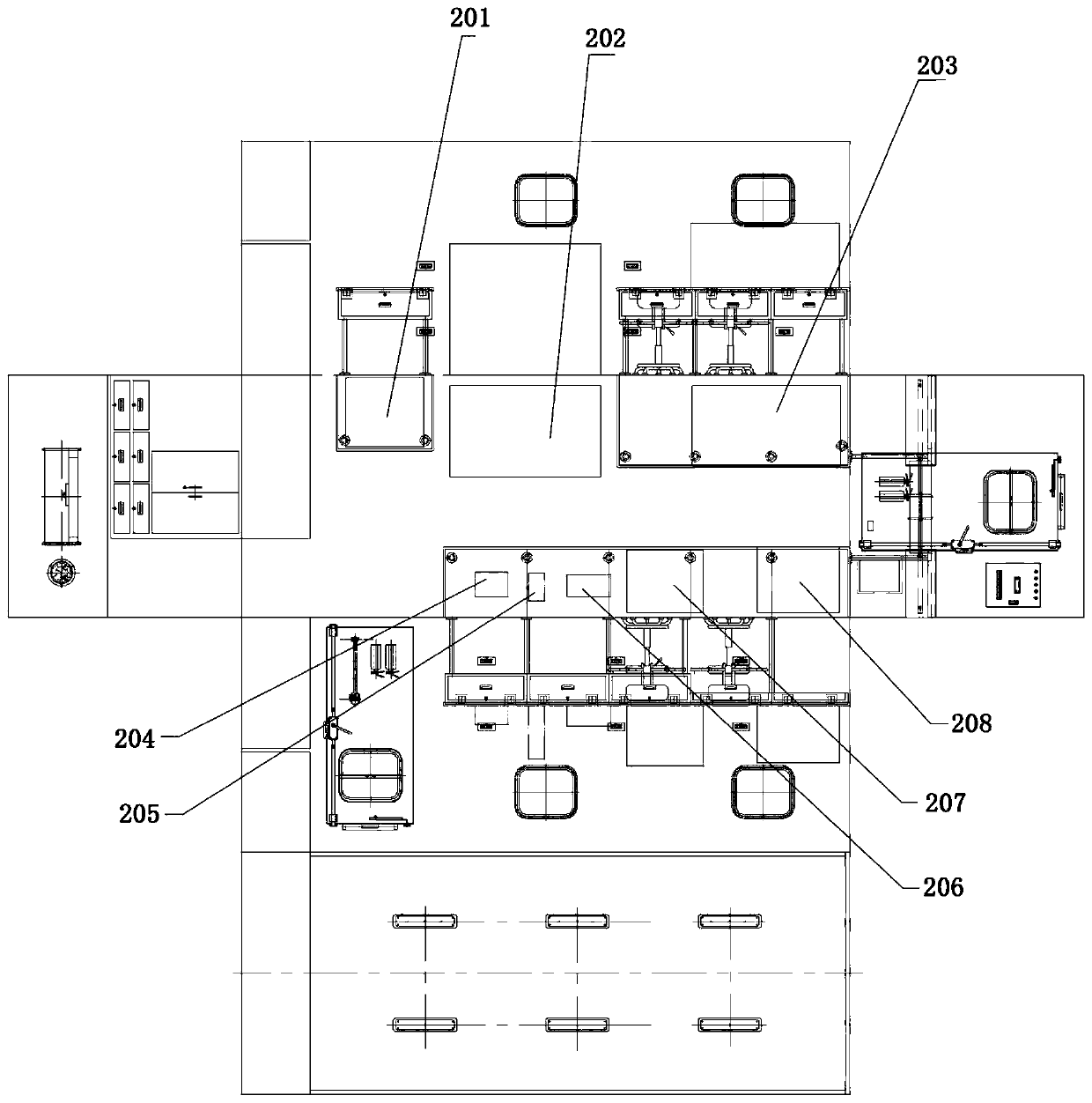

[0040] On the basis of embodiment 1 or 2, with reference to image 3 As shown, the cabin body 1 of the clinical testing unit M8 is equipped with a POCT module 201, a biochemical analyzer 202, an immune analyzer 203, a blood gas analyzer 204, a microscope module 205, a centrifuge 206, a blood cell analyzer 207, a urine liquid analyzer 208, the POCT module 201, biochemical analyzer 202, immune analyzer 203, blood gas analyzer 204, microscope module 205, centrifuge 206, blood cell analyzer 207, and urine analyzer 208 are arranged in two rows relative to each other Close to the position of the side wall of the shelter body 1.

[0041] In this embodiment, the shelter body 1 is equipped with POCT module 201, biochemical analyzer 202, immune analyzer 203, blood gas analyzer 204, microscope module 205, centrifuge 206, blood cell analyzer 207, urine analyzer 208 and other modules , instruments, according to the patient's condition diagnosis requirements, carry out clinical hematology,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com