Mold for stamping of thin material

A thin material and mold technology, applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc., can solve problems such as arching, easily damaged mold parts, and prone to errors, so as to avoid misdelivery and reduce machine tool costs , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

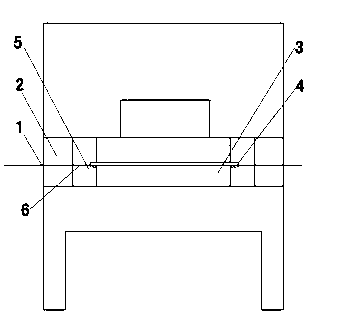

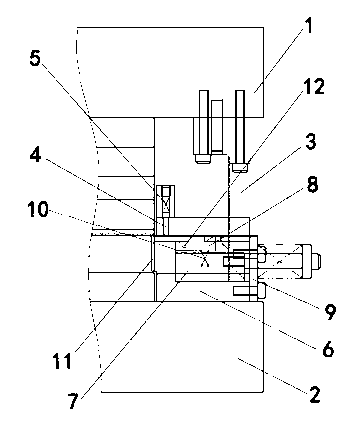

[0015] The invention discloses a mold for stamping thin materials, which comprises upper and lower molds and a material pulling mechanism. Small holes are evenly opened on both sides of the thin material. to combine figure 2 , image 3 As shown, the material pulling mechanism is arranged at the material outlet of the mold belt, and includes a material pulling base 6 , and the material pulling base 6 is fixed on the lower mold 2 through a slot 11 .

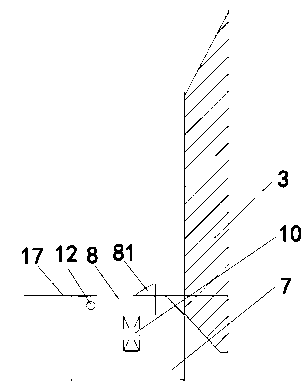

[0016] A linear track (not shown in the figure) is provided on the pulling material base 6, and a slider 7 is arranged for moving in the linear track, and a pulling block 8 and a spring 10 are fixed on the sliding block 7, and the pulling block 8 One end is fixed on the sliding block 7 through a positioning pin 12, the spring 10 is against the bottom of the other end of the pulling block 8, and the top end 81 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com