Intelligent garbage classification device

A garbage classification and intelligent technology, applied in trash cans, garbage collection, garbage cleaning, etc., can solve the problems of random placement, errors, and cumbersome placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

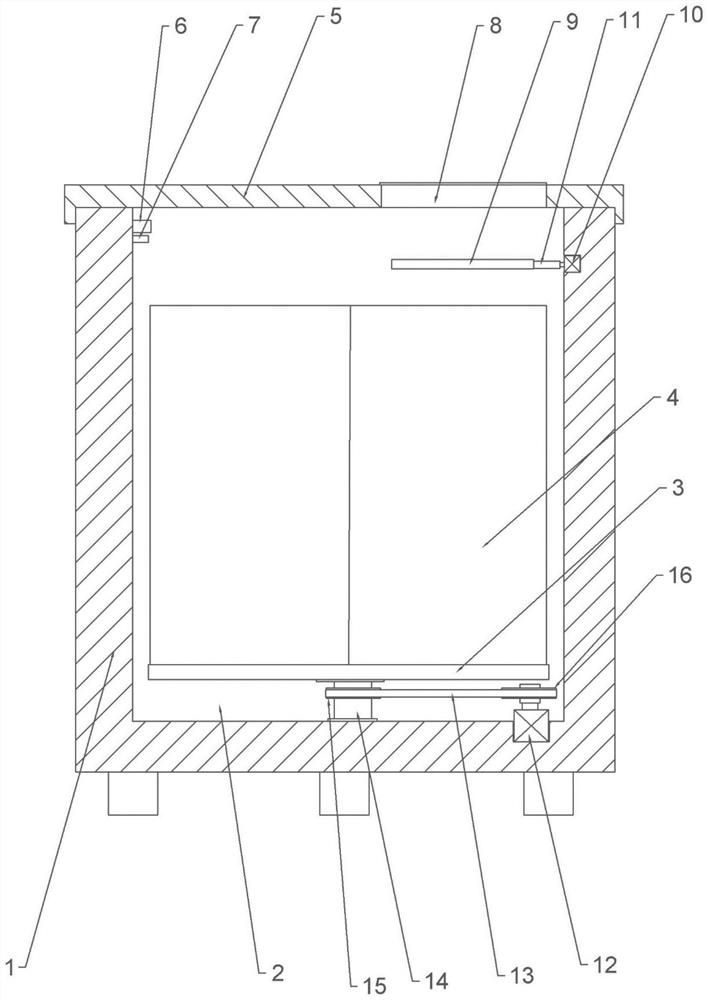

Examples

Embodiment 2

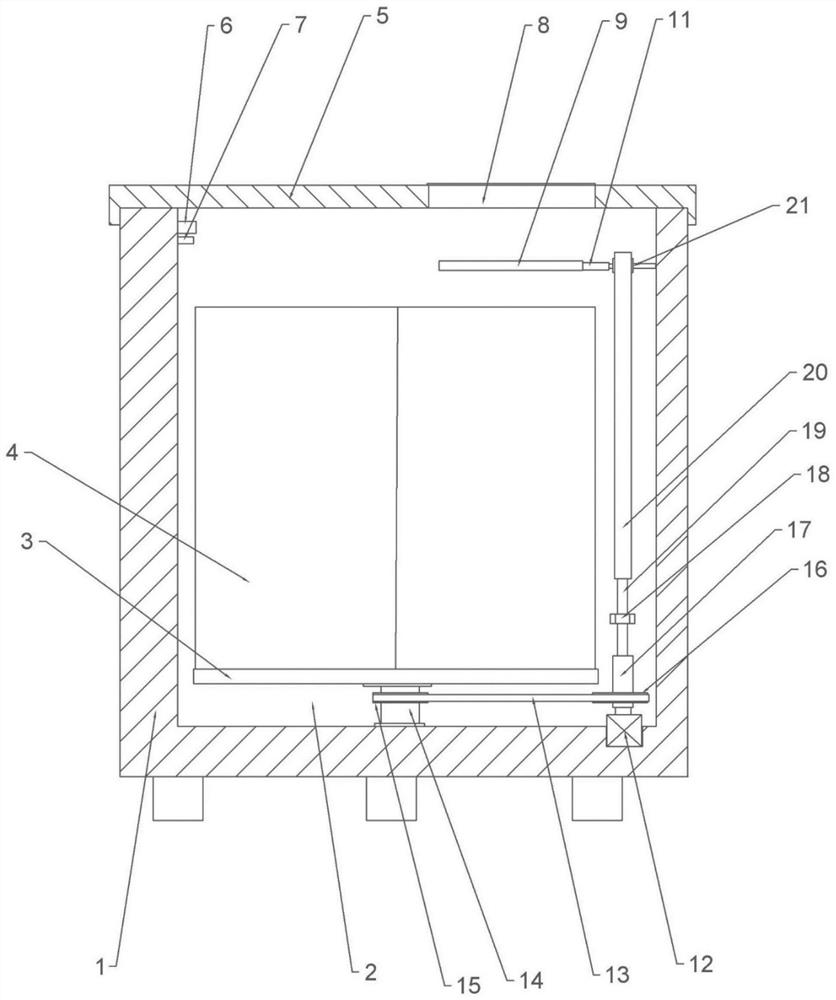

[0031] Such as figure 2As shown, the difference between this embodiment and Embodiment 1 is that this embodiment also includes a transmission part, which includes a screw 19 , a threaded part, a rack 20 and a gear 21 , and the threaded part in this embodiment is a nut 18 . One end of the screw rod 19 is a polished rod, and the lower end of the rack 20 is rotationally connected with the end of the polished rod of the screw rod 19. The connection method is the prior art, known to those skilled in the art, and will not be repeated here. The screw rod 19 passes through the nut 18 and is threadedly engaged with the nut 18 , and the nut 18 is welded to the inner wall of the housing 1 . There is a cavity on the top of the rotating shaft 17, and a protrusion is welded on the side wall of the cavity. The side wall of the screw rod 19 is provided with a sliding groove, and the screw rod 19 extends into the cavity and can slide and fit with the cavity; the protrusion snaps into the sli...

Embodiment 3

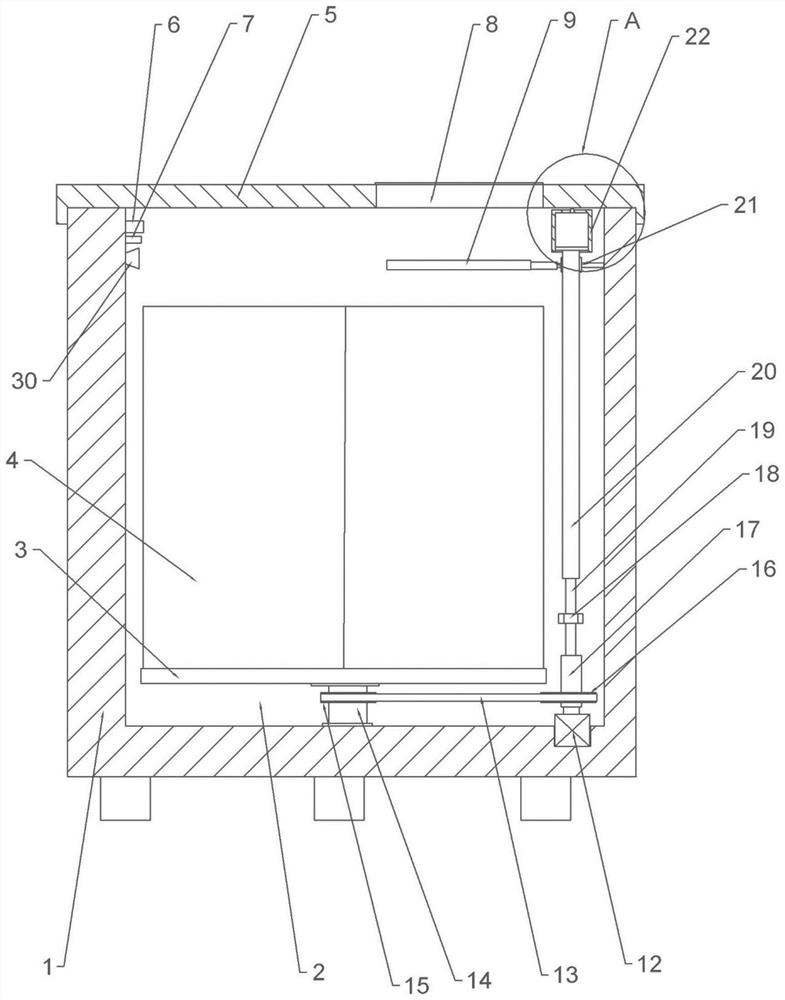

[0036] Such as image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that a disinfection structure is also provided in this embodiment. The disinfection structure includes a cylinder body 22 , a connecting pipe (not shown in the figure) and a nozzle 30 , the nozzle 30 is clamped on the side wall of the recovery cavity 2 and the nozzle 30 is located above the recovery bucket 4 . The number of shower heads 30 can be multiple ( image 3 only one of them is shown). The cylinder body 22 is welded on the upper part of the side wall of the recovery chamber 2, the cylinder body 22 is a liquid storage chamber 23, the liquid storage chamber 23 is filled with disinfectant and the liquid storage chamber 23 is sealed and slidingly connected with a piston 24, the lower end of the piston 24 is connected to the rack 20 upper ends are clamped. The upper end of the cylinder body 22 is provided with a liquid outlet 25, and the two ends of the communicati...

Embodiment 4

[0039] Such as Figure 5 and Figure 6 As shown, the difference between the present embodiment and the third embodiment is that the present embodiment also includes a suction pump (not shown in the figure), a suction pipe 33, a baffle plate 28, a connecting rod 29 and a casing 32, the casing 32 covers are arranged on the lower end of the receiving plate 9 and form a relatively sealed area with the receiving plate 9. The lower end of the casing 32 is connected with the suction pipe 33, and the suction pipe 33 is connected with the suction pump. The connection methods are all in the prior art. This will not be repeated here. A plurality of suction ports 26 are evenly opened on the upper end surface of the receiving plate 9, and the suction ports 26 pass through the receiving plate 9, and a cylinder 31 is fixed on the lower end of the receiving plate 9 by screws, and the output shaft of the cylinder 31 is clamped with one end of the connecting rod 29 , the other end of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com