Chain type material bag

A material package and chain type technology, applied in the field of chain material package, can solve the problems of affecting work efficiency, occupying space, increasing costs, etc., and achieve the effects of convenient operation, avoiding adding materials, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

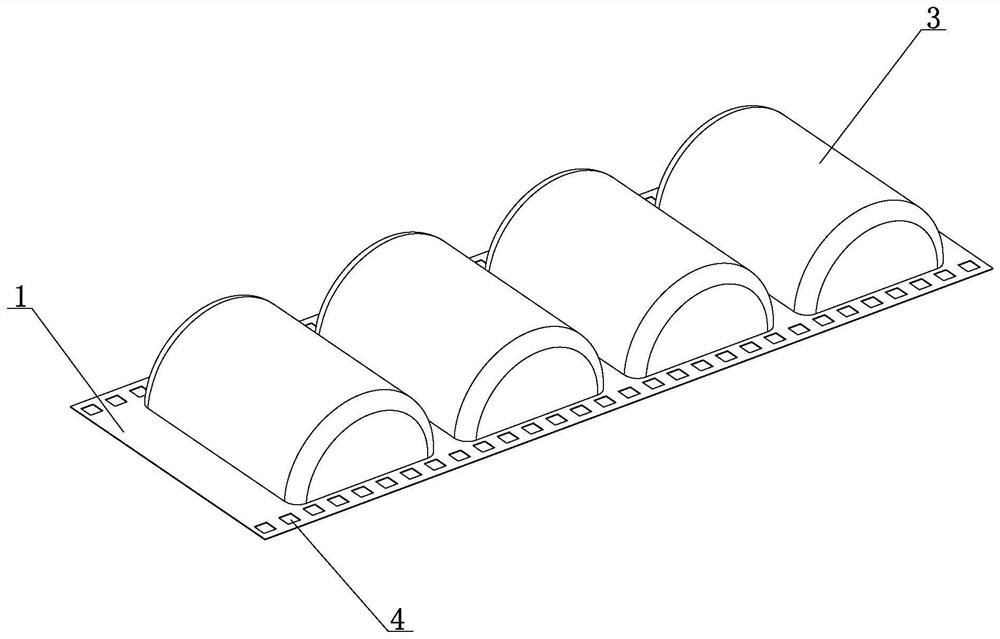

[0025] Such as figure 1 and Figure 5 As shown, the present invention discloses a chain-type material package with the following structure: it includes a base plate 1 and a box body 2; there are multiple box bodies 2 distributed on the base plate 1 at even intervals; the box body 2 is provided with a supply material In the accommodating cavity, transmission parts for transmission connection of the transmission mechanism are evenly distributed on the base plate 1 . Put the various materials that need to be put into the equipment into the box body 2 connected to the substrate 1 in sequence according to the required amount and the order of putting in, and transport them to the delivery position through the transmission mechanism, and break the box body 2 to put in the materials, no need Equipped with too many hoppers and feeding devices, it is not only easy to operate and low in cost, but also avoids the subsequent feeding and cleaning of the silos; the empty box body 2 or the u...

Embodiment 2

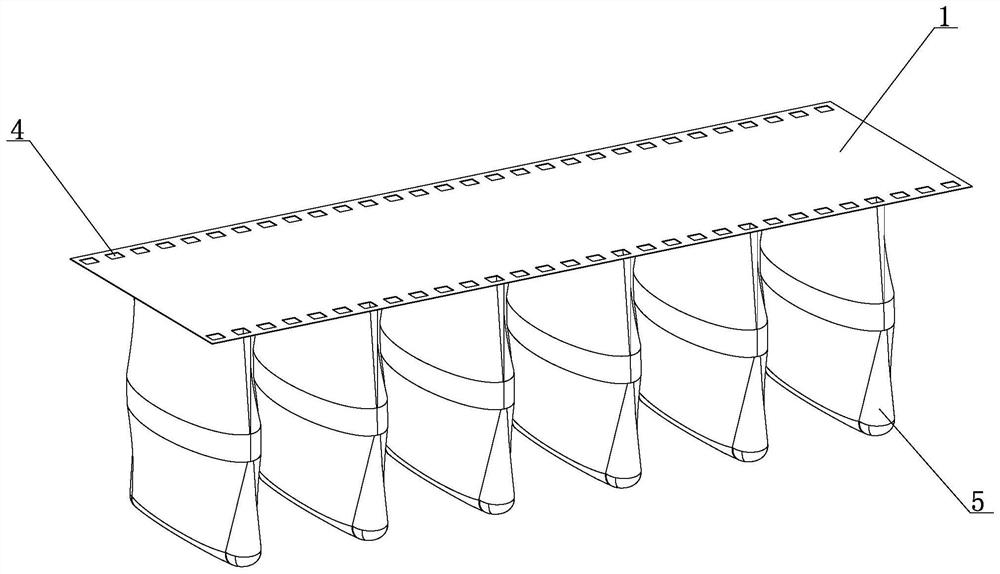

[0029] Such as figure 2 As shown, it is the same as Embodiment 1, the only difference is that the box body 2 is a material bag 5 (such as a transparent plastic bag) made of a flexible material, and the material bag 5 is arranged on the substrate 1 at intervals and is located on the same side of the substrate 1 .

Embodiment 3

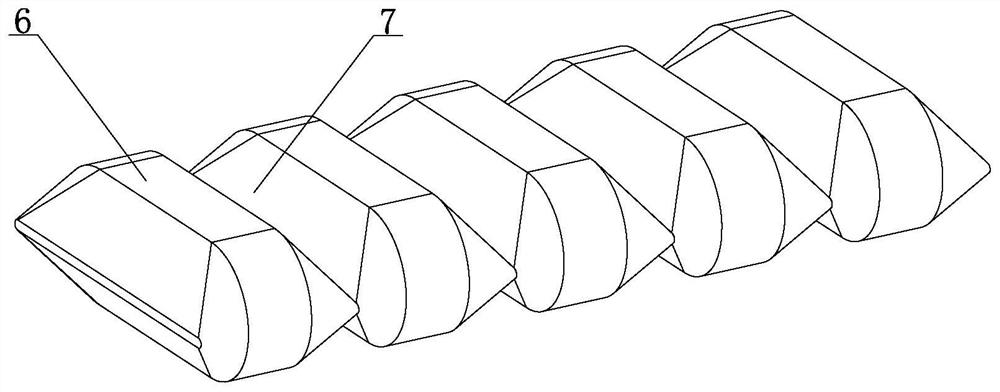

[0031] Such as image 3 As shown, it is the same as Embodiment 1, the only difference is that the box body 2 is a material package 6 made of flexible material, and the material packages 6 are connected in series through the substrate 1; the height of the material package 6 gradually decreases from the middle to both ends, The transmission part is a groove 7 formed between two adjacent material packages 6; the transmission mechanism is two sprockets symmetrically arranged above and below the material package 6, and the protruding teeth of the sprocket are engaged with the groove 7 for transmission. The material bag 6 is filled with gas, and the accommodating cavity of the material bag 6 has a certain air pressure to ensure that the size of the material bag 6 is the same, so that the protruding teeth of the sprocket are inserted into the groove 7 for transmission. The gas can be nitrogen, which has low cost and is not easy to cause material deterioration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com