Pipeline trepanning process

A pipeline and process technology, applied in the field of pipeline opening technology, can solve the problems of poor test effect and random construction operation, etc., and achieve the effects of convenient realization, convenient and reasonable layout, and simple method steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

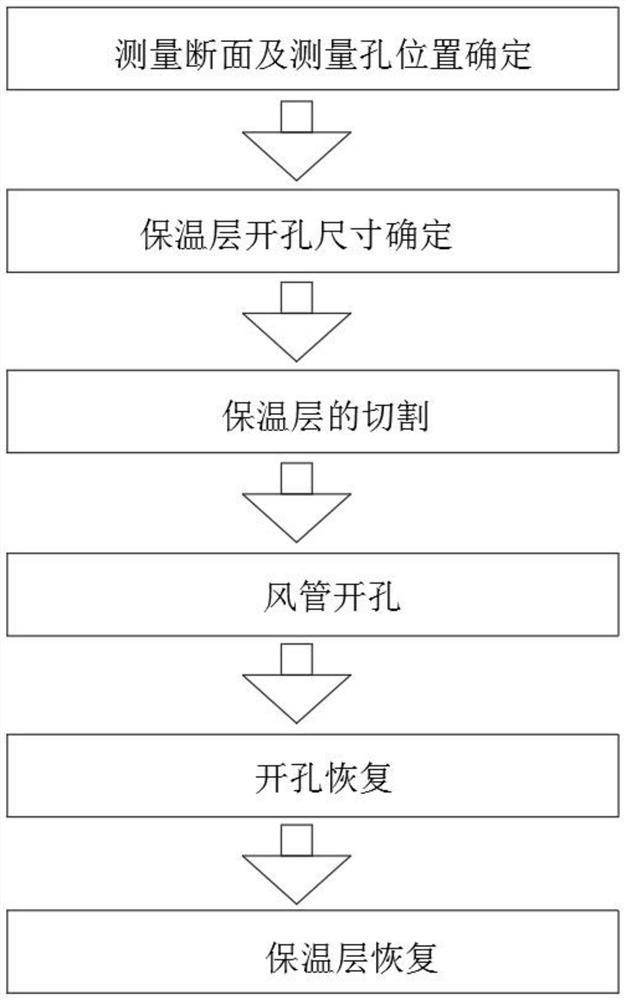

[0029] Such as figure 1 As shown, the pipeline drilling process includes the following steps:

[0030] Step 1. Determining the measurement section and the location of the measurement hole: according to the pre-designed test requirements of the ventilation and air conditioning system to be tested, the number of test sections to be tested on the air duct to be tested, the position of each test section and the location of each test section are determined. The number of measuring holes to be opened and the hole positions of each measuring hole are determined respectively; the test section is the cross-section of the air duct to be tested at its position, and the number of measuring holes is set on each of the test sections. There are multiple measurement holes, and the multiple measurement holes are all located on the same plane to avoid errors affecting subsequent operations. The problem that the local strength of the air duct is reduced and the reinforcement is difficult due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com