Automated integrated type test system

An inspection system and integrated technology, applied in conveyor objects, conveyors, mechanical conveyors, etc., can solve the problems of inability to cooperate with other units in the hospital, wasting manpower, prolonging time, etc., to achieve high-efficiency interpretation and operation instructions, increase Overall inspection efficiency, the effect of accelerated inspection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Other technical contents, features and functions of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the drawings.

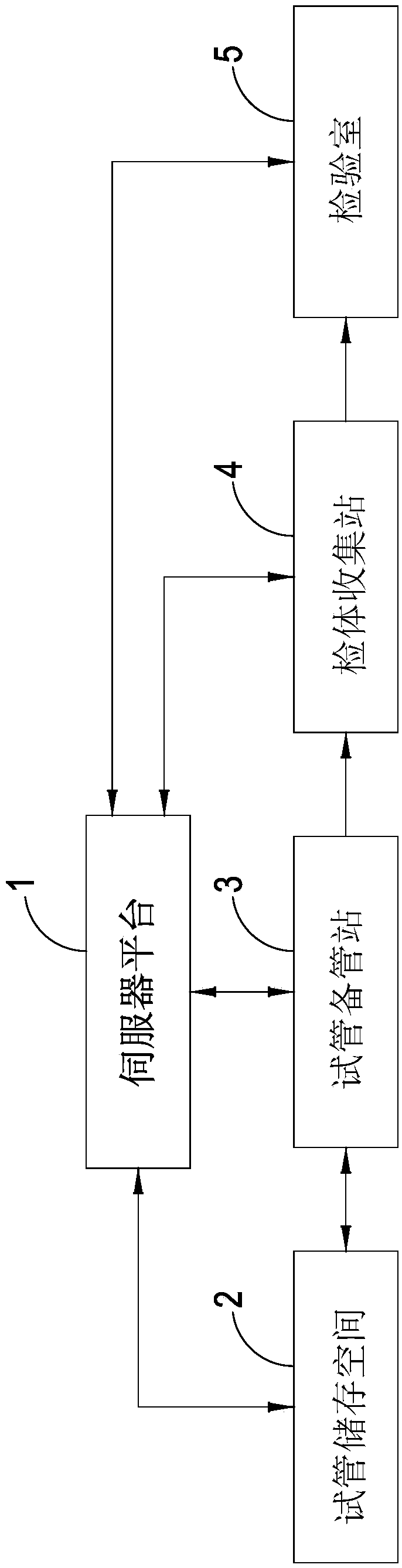

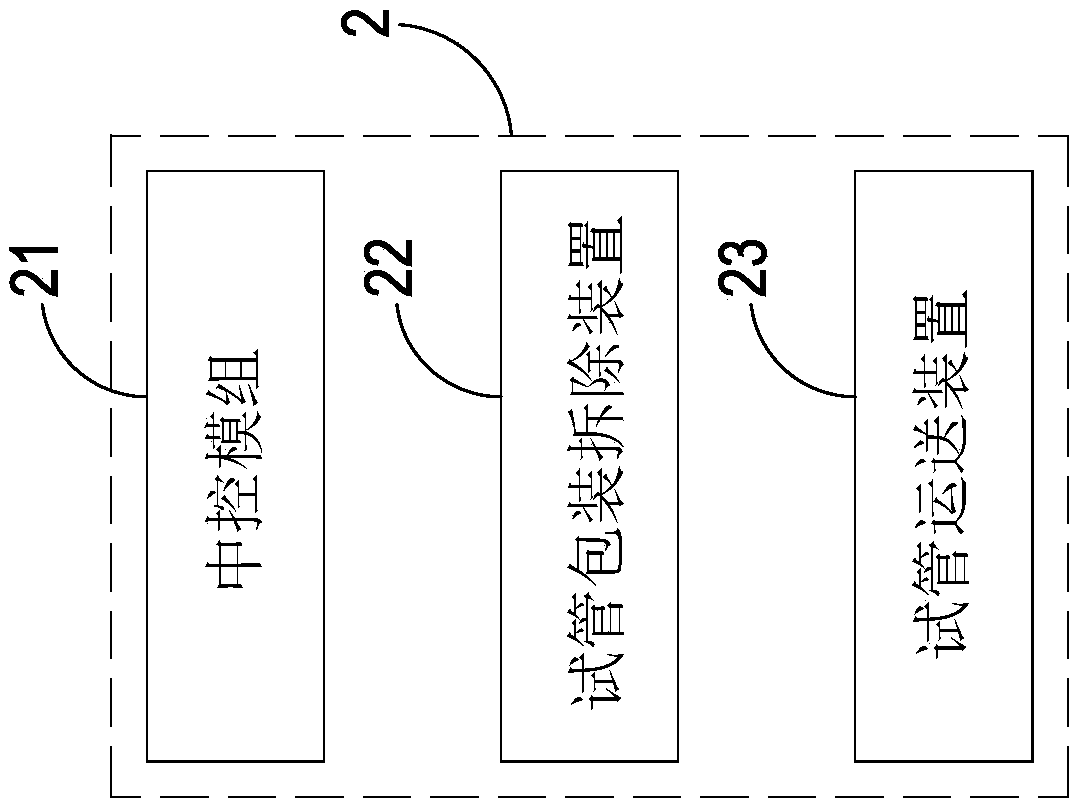

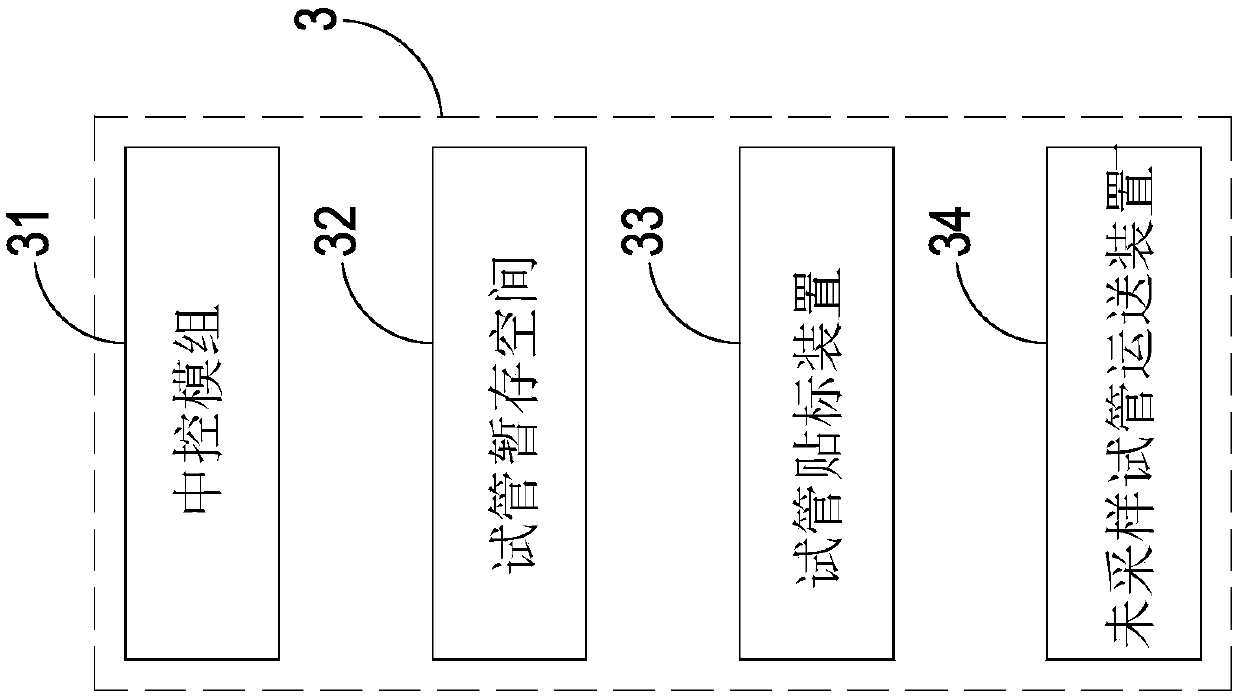

[0058] see figure 1, is a schematic diagram of the overall structure of the automated integrated inspection system of the present invention. It can be seen from the figure that the automated integrated inspection system includes a server platform 1, a test tube storage space 2, at least one test tube preparation station 3, at least one inspection Body collection station 4, at least one inspection room 5, wherein the server platform 1 can be used to centrally integrate and control the operation of the overall system, in addition to record any data generated by the operation of the automated integrated inspection system , and the test tube storage space 2 is designed to allow various unsampled test tubes and blood-drawing devices to be stored in fixed positions. Since the unsamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com