Tensioning locking and lossless extending device

A technology of tensioning and wedge-shaped sliders, which is applied in the field of concrete components, can solve problems such as damage to concrete, loss of prestress, and loss of elongation, and achieve the effects of simple fabrication, convenient operation, and large-scale construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

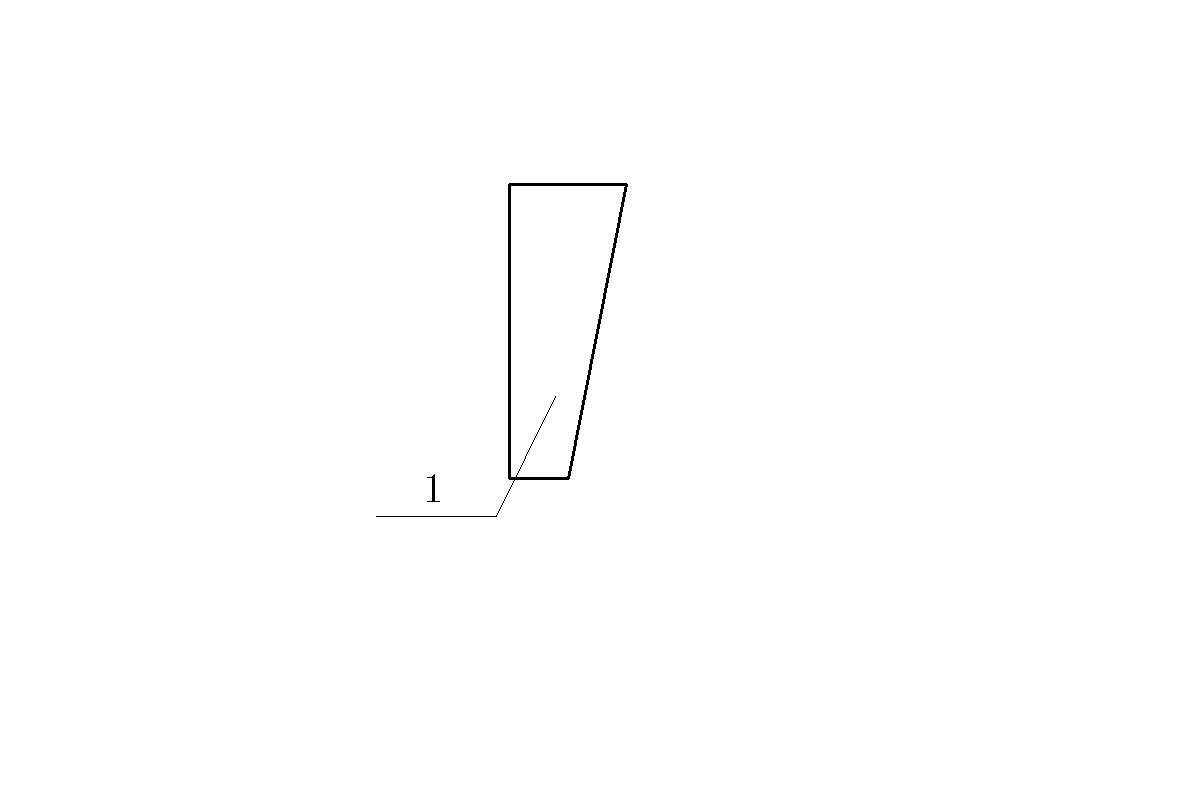

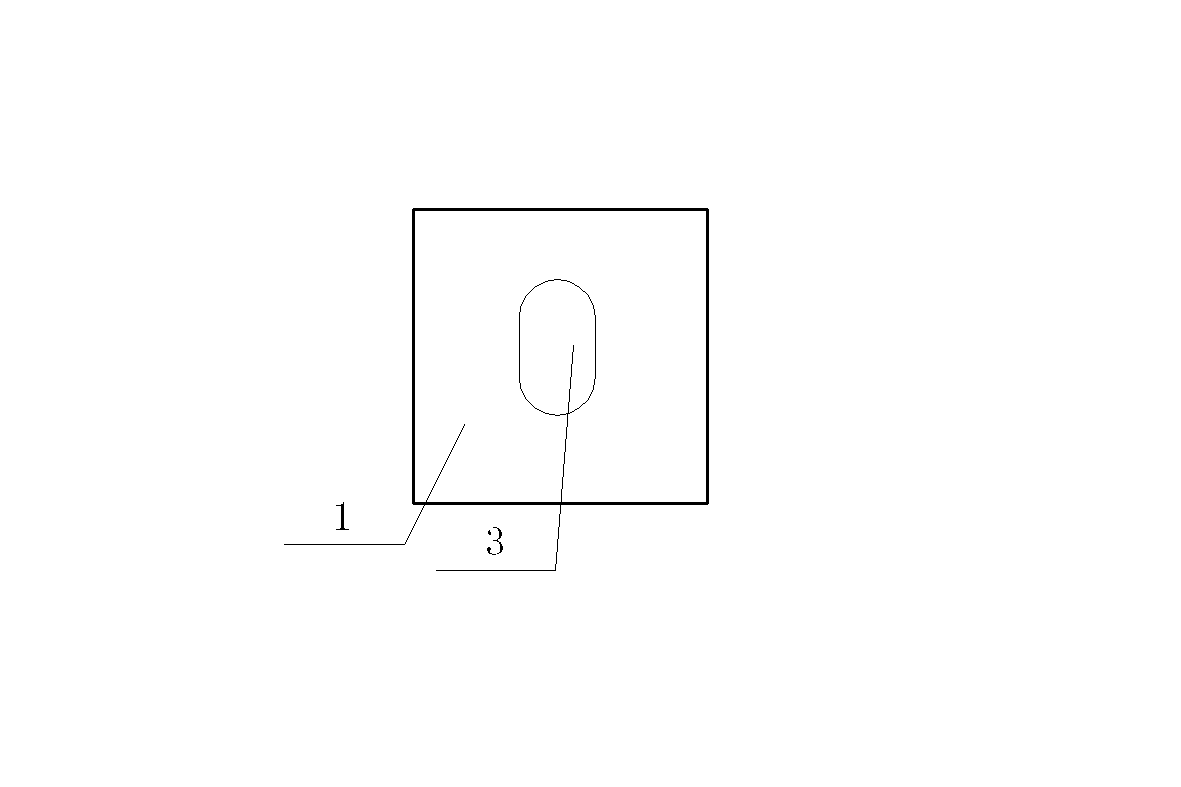

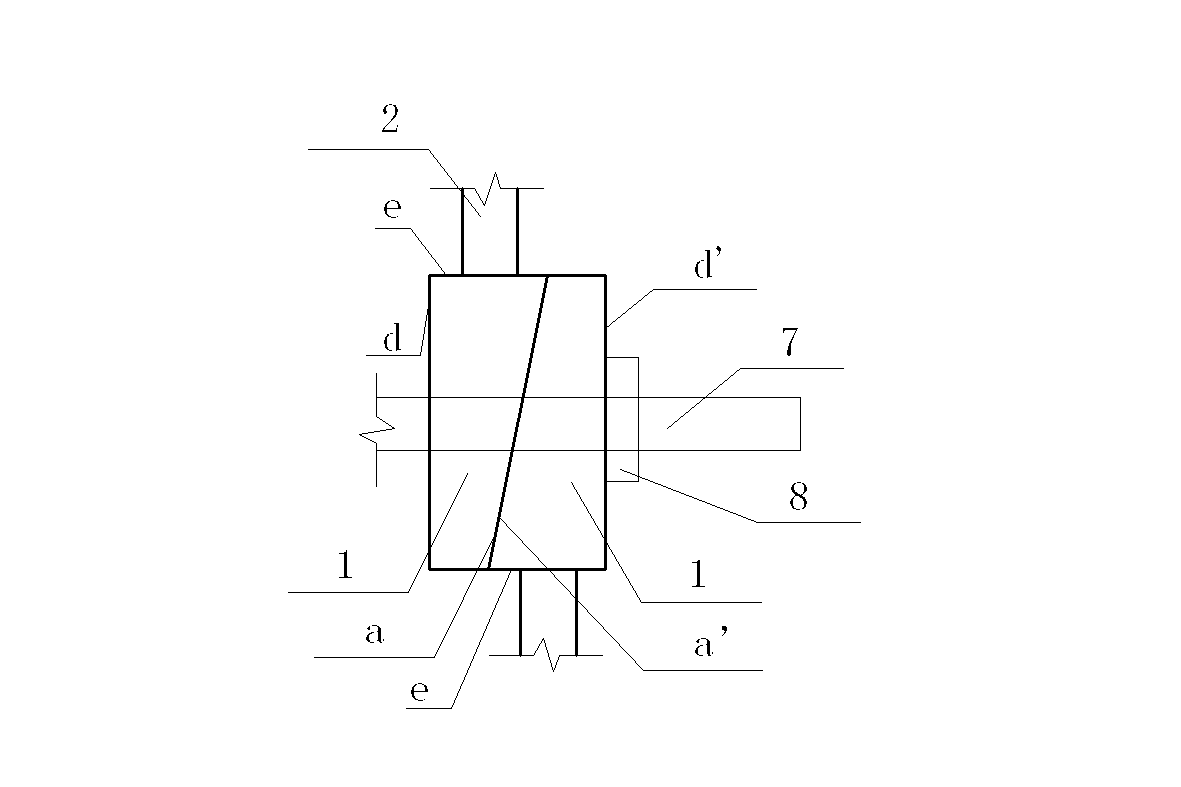

[0020] Embodiment 1: as Figure 1-4 As shown, a tension locking and non-destructive release device includes two wedge-shaped sliders I1 and two jacking bolts 2, and two wedge-shaped sliders I1 are formed with long holes 3, and two wedge-shaped sliders I1 Placed close to each other, the contact surfaces a and a' of the two wedge-shaped sliders I1 are inclined surfaces with complementary inclination angles, and the surfaces opposite to the contact surfaces a and a' of the two wedge-shaped sliders are vertical planes d and d' respectively, and the two wedge-shaped sliders I1 are respectively tightened by the tightening bolts 2, and the tightening bolts 2 are supported on the plane e of the wedge-shaped slider I1, and the plane e is a relatively wide plane perpendicular to the length direction of the elongated hole 3.

Embodiment 2

[0021] Embodiment 2: as Figure 5-10 As shown, a tension locking and non-destructive release device includes three wedge-shaped sliders and a jacking bolt 2, and the three wedge-shaped sliders are placed side by side in sequence. The three wedge-shaped sliders are divided into two types, of which One side of the wedge-shaped slider II5 located at both ends is a slope, and the opposite side of the slope is a vertical plane, on which a round hole 4 is formed, and both sides of the wedge-shaped slider III6 in the center are slopes, and a long hole is formed on it. Bar hole 3; the contact surfaces a, a', b, b' of the adjacent wedge-shaped sliders are inclined surfaces with complementary inclination angles, and the centered wedge-shaped slider III6 is tightened by the tightening bolt 2, which is pressed against the wedge-shaped slider. On the plane f of the block III6, the plane f is a relatively wide plane perpendicular to the length direction of the long hole 3 .

Embodiment 3

[0022] Embodiment 3: as Figure 11 , 12 As shown, a tension locking and non-destructive release device includes four wedge-shaped sliders and two jacking bolts 2, and each wedge-shaped slider is placed side by side in sequence. Embodiment 3, the inside of the wedge-shaped slider II5 positioned at both ends is a slope, and the outside is a vertical plane, on which a round hole 4 is formed; the two sides of the wedge-shaped slider III6 located in the middle are slopes, and the sides are formed on it. There are elongated holes 3, and the contact surfaces a, a', b, b', c, c' of the adjacent wedge-shaped sliders are inclined surfaces with complementary inclination angles, and the two tightening bolts 2 respectively push against the two wedge-shaped sliders in the middle. On the plane f of the block III6, the plane f is a relatively wide plane perpendicular to the length direction of the long hole 3 .

[0023] There are two stages in use, the first stage is the tension locking sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com