Railway passenger train body

A rail passenger car and car body technology, applied in railway car body parts, transportation and packaging, etc., can solve the problems of wasting manpower, large passenger flow, and inability to use, and achieve the effect of improving safety and ensuring train running speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The "longitudinal" mentioned in this article refers to the running direction of the rail passenger car, and the "transverse" refers to the vertical and "longitudinal" directions in the horizontal plane. Generally speaking, "longitudinal" refers to the length direction of the rail passenger car, and "horizontal" refers to the width direction of the rail passenger car.

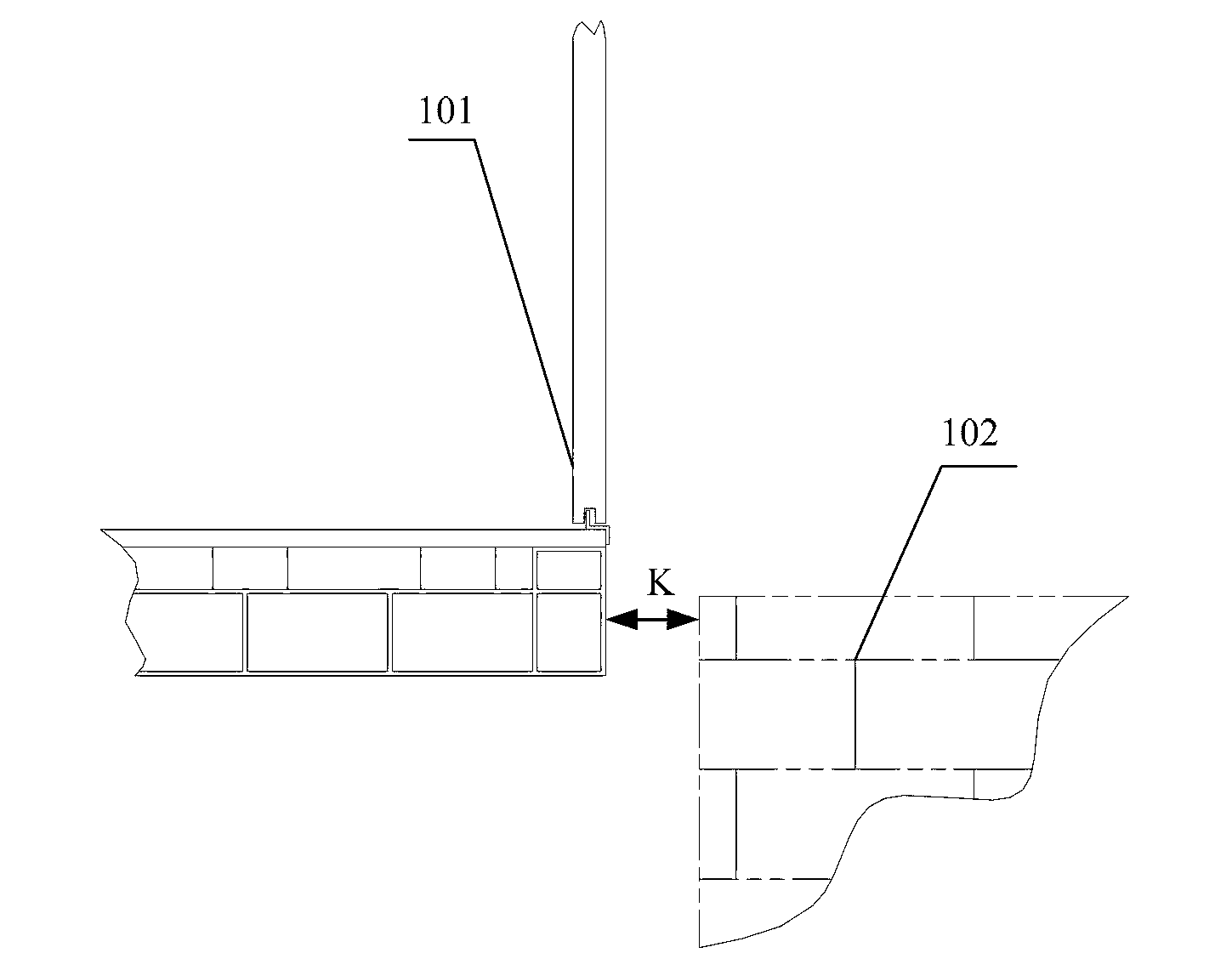

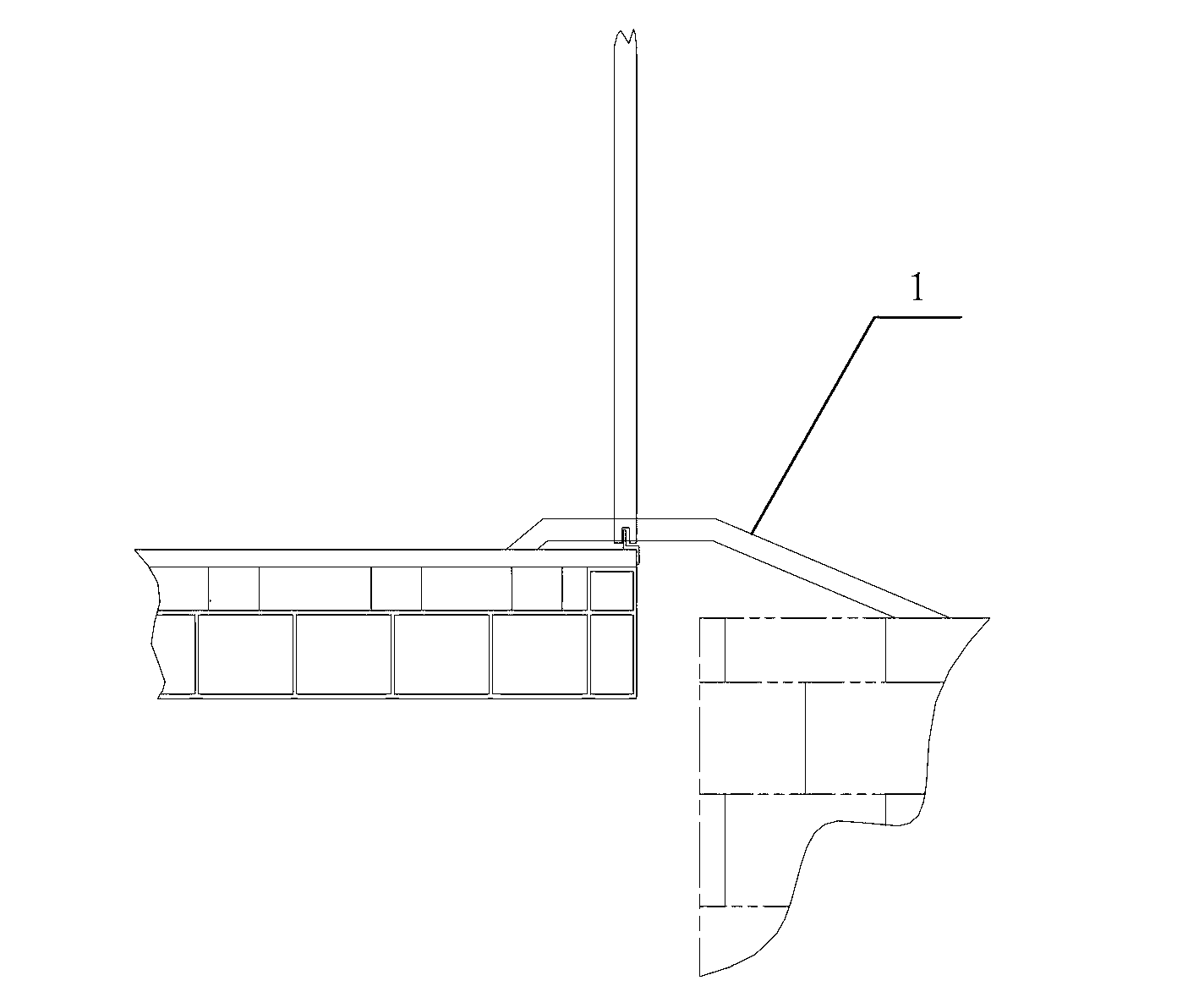

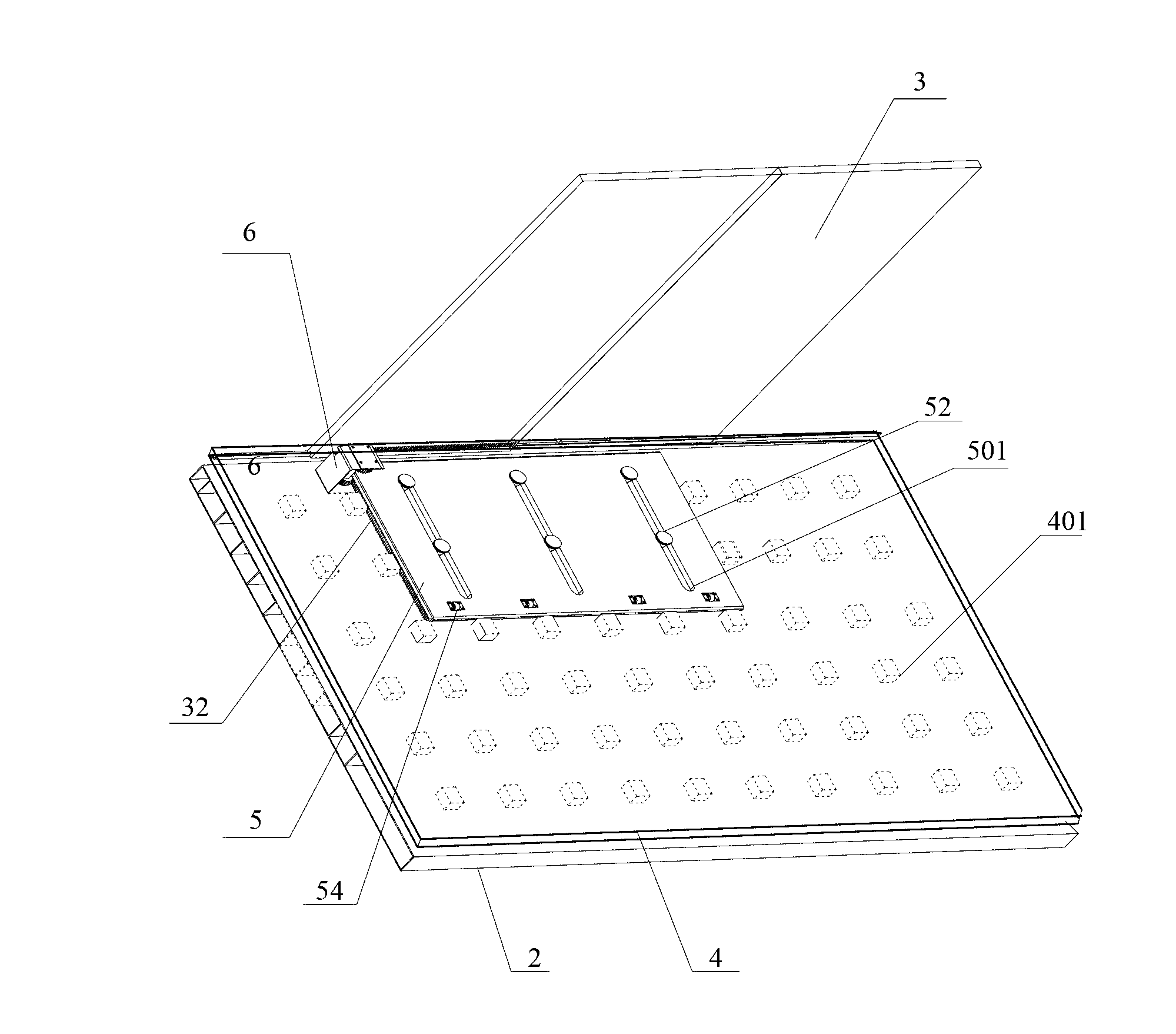

[0020] The invention provides a rail passenger car body, please refer to Figure 2-6 , Figure 8 and Figure 10 , comprising: a car body floor 2 extending longitudinally and car body side walls (not shown) fixedly arranged on both sides of the car body floor 2, at least one side wall of the car body on at least one side is provided with at least one door for passengers to get on and off The passage port is provided with a sliding door 3 that can be opened by pushing and pulling; the car body floor 2 is covered with an interior trim floor 4, and a first gap is formed between the interior trim floor 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com