Multi-knuckle-arm retracting mechanism and engineering machinery vehicle

A telescopic mechanism and articulated arm technology, applied in cranes, fire rescue and other directions, can solve problems such as reducing the stability of the telescopic oil cylinder and the stability of the telescopic mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

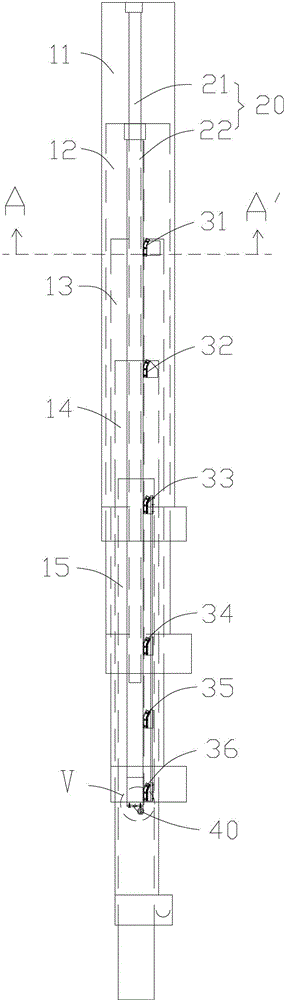

[0031] see figure 1 , is a structural schematic diagram of an embodiment of the multi-section boom telescoping mechanism of the present invention.

[0032] The multi-section arm telescoping mechanism of this embodiment includes but is not limited to at least the first section arm 11, the second section arm 12 and the third section arm 13 which are arranged in sequence, which can be used for engineering machinery vehicles such as fire trucks or cranes. , Construction machinery and equipment, not limited here.

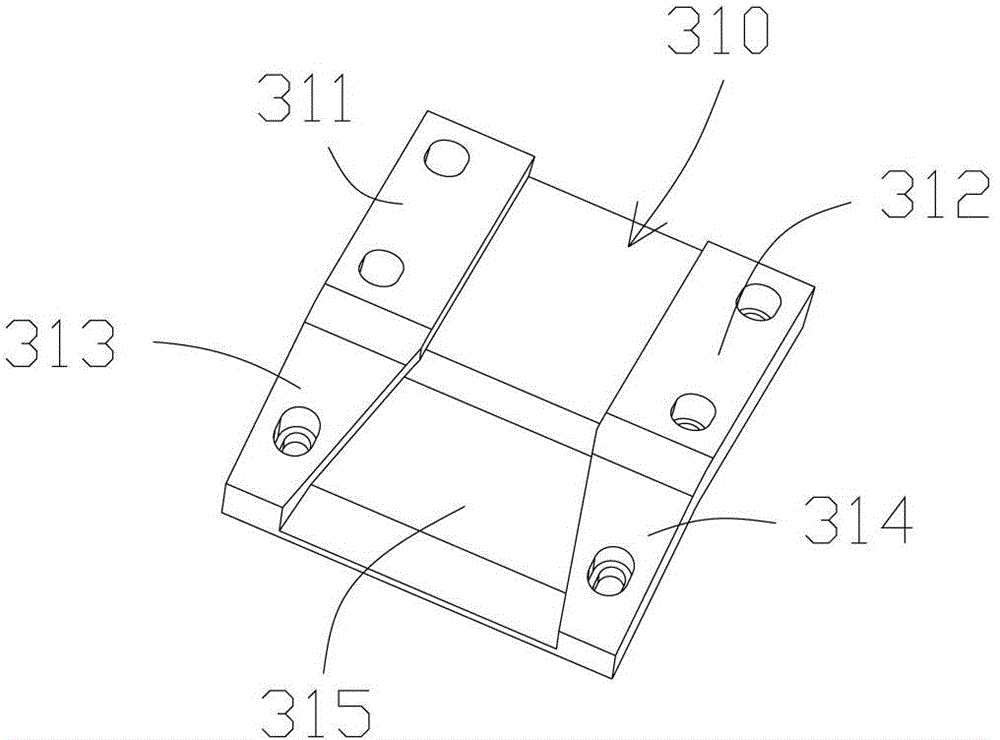

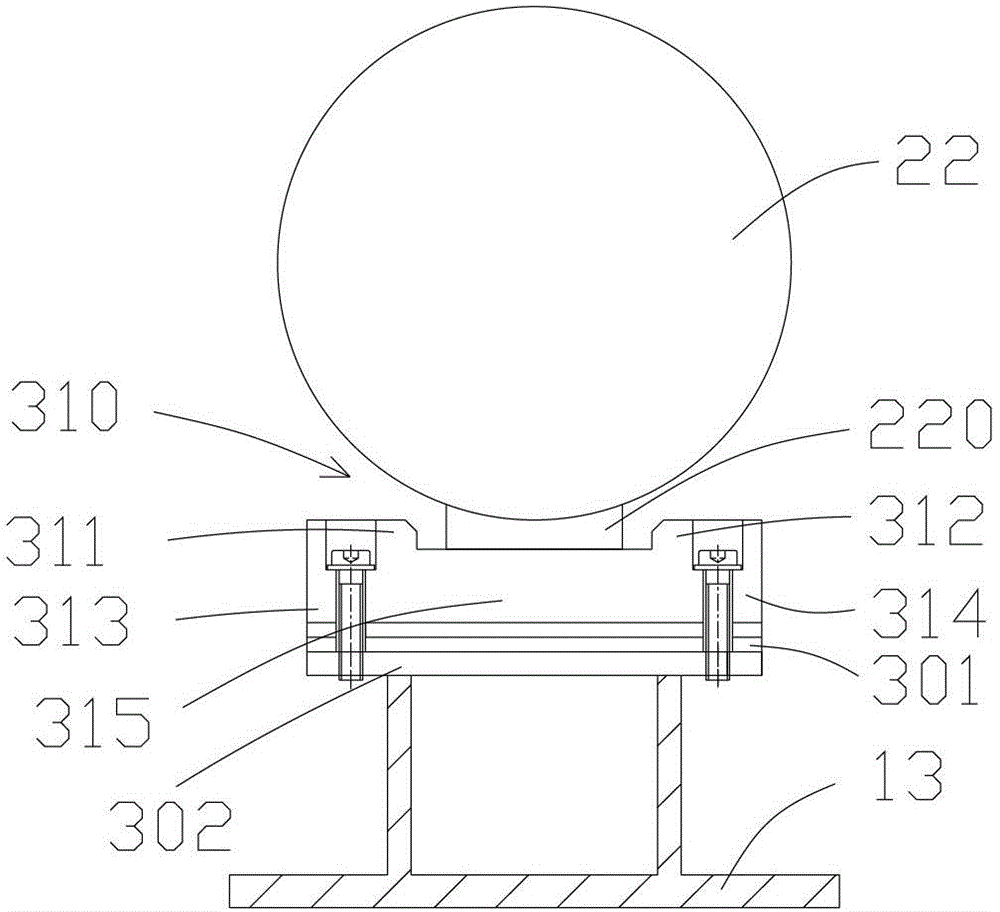

[0033] In this embodiment, the multi-section boom telescopic mechanism may also include a telescopic oil cylinder 20 and a supporting device. The telescopic oil cylinder 20 includes a piston rod 21 and a cylinder body 22. The telescopic oil cylinder 20 is installed in the multi-section arm of the multi-section arm telescopic mechanism. When installing, the piston rod 21 is fixedly connected with the first section arm 11, and the cylinder body 22 is connected with the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com