Grouting Anchor Cable and Grouting Method in Deep Surrounding Rock of Roadway

A technology of grouting anchor cables and surrounding rocks, which is applied in the direction of earthwork drilling, bolt installation, mining equipment, etc. It can solve the problems of low efficiency and difficulty in grouting the surrounding rocks in the deep part of the roadway, and achieve the effect of improving efficiency and ensuring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

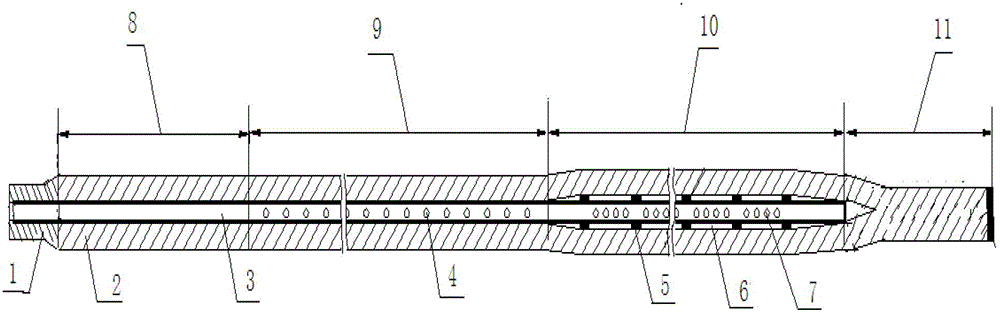

[0012] Such as figure 1 As shown, the roadway deep surrounding rock grouting anchor cable of the present invention includes a grouting anchor cable body with a grouting core pipe 3 in the middle, and the bottom section of the anchor cable body hole is an anchoring agent anchoring section 11 without a grouting core pipe. An anchor head 1 is provided at the orifice end of the anchor cable body; wherein, the grouting core pipe 3 is divided into three sections from the orifice; the grouting core pipe 3 of the first section remains in its original state; High-pressure slurry flow holes 4 are arranged at regular intervals around the body of the slurry core pipe 3; a metal sleeve 5 is placed on the body of the third section of the grouting core pipe 3 at intervals, and the metal sleeve 5 anchors the The cable steel strand 2 is propped up, so that there is an interval gap section 6 between the anchor cable strand 2 and the grouting core pipe 3, and the grouting core pipe 3 pipe body o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com