Plug-in mounting

A mounting piece and insert-type technology, applied in the field of insert-type mounting pieces, can solve the problems of weak, cumbersome, and easy to loose plane docking, achieve a simple and fast installation process, eliminate stone slab thickness errors, and make stone slabs firm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

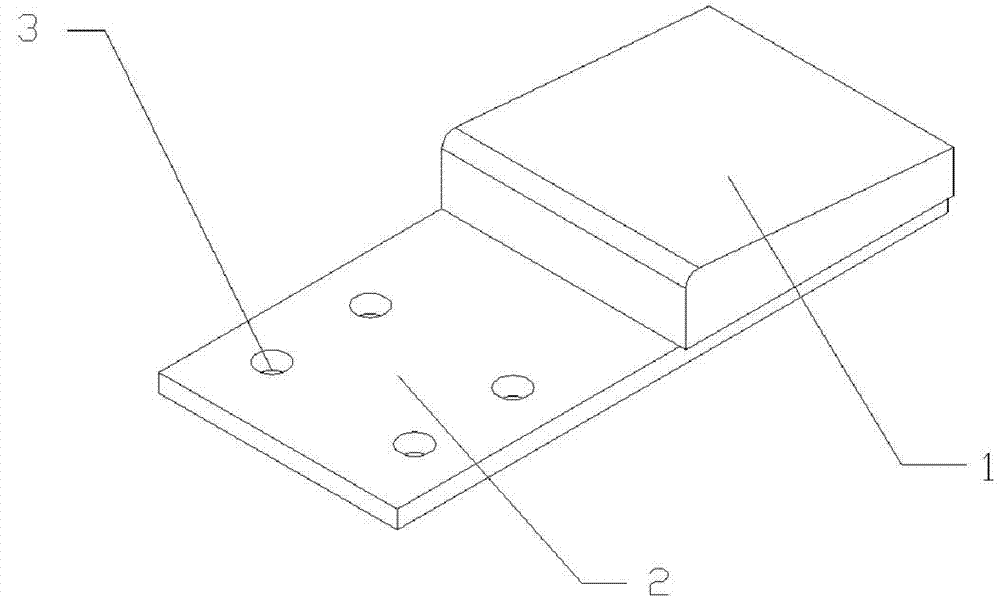

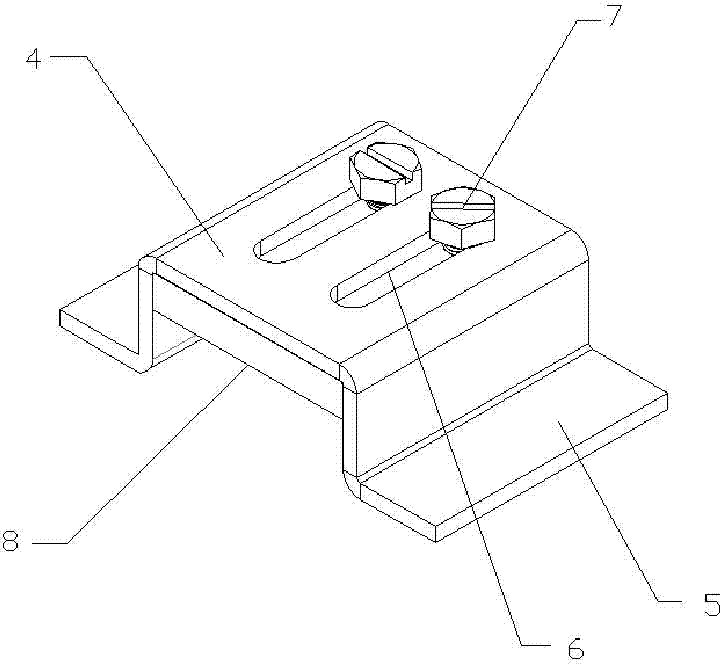

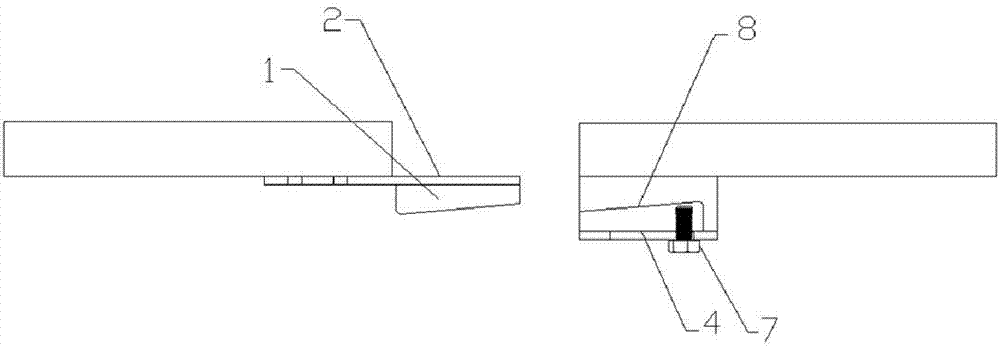

[0011] refer to figure 1 As shown, the insert 8-type mounting part includes an insert device and a slot device, and the insert device includes a base 2 and a wedge-shaped insert 1 arranged on the base 2, and the base 2 is longer than the base 2. The wedge-shaped plug 1; the slot device includes a plug box 4 and a fixed wing 5, the inside of the plug box 4 is provided with an insert 8, the top is provided with an adjustment hole 6 and an adjustment screw 7, and the insert 8 will insert A part of space suitable for the wedge-shaped plug 1 is separated inside the box 4 .

[0012] The 8-insert mounting piece obtained in the present invention can eliminate the thickness error of the stone slab during the installation process, and the stone slab surface is firm after installation and is not easy to loosen; in addition, the installation process during construction is simple and fast, and can achieve seamless connection Effect.

[0013] Preferably, two elongated adjustment holes 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com