Gravity angled-sliding type installation part

A mounting piece and oblique sliding technology, which is applied in the field of gravity oblique sliding type mounting parts, can solve the problems of unreliable plane butt joint, difficult adjustment, cumbersome and other problems, achieve simple and fast installation process, eliminate stone plate thickness error, and make the stone plate surface firm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

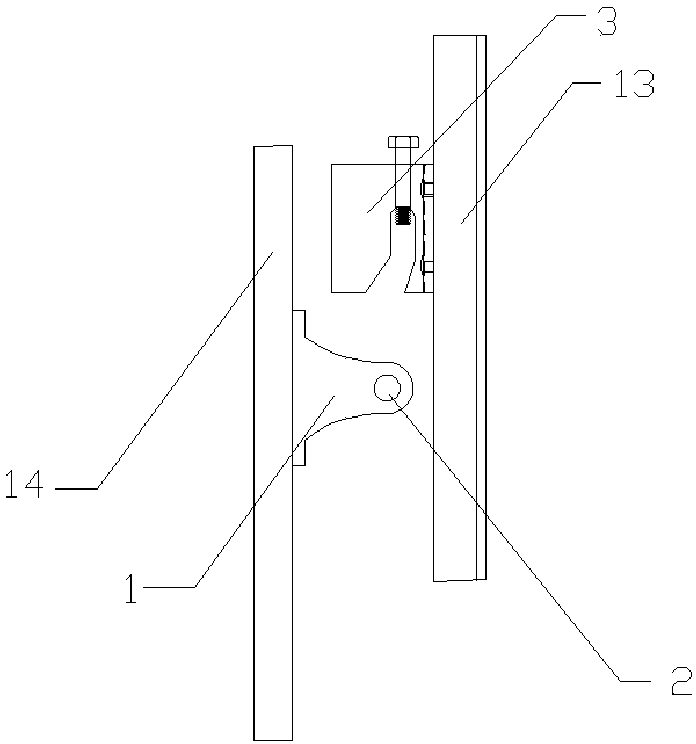

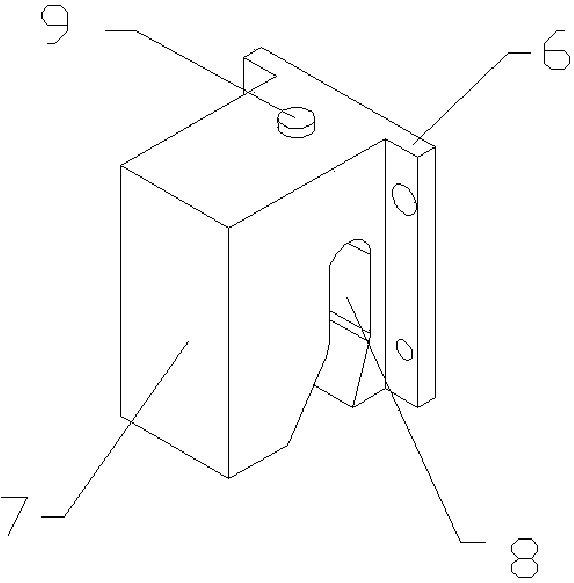

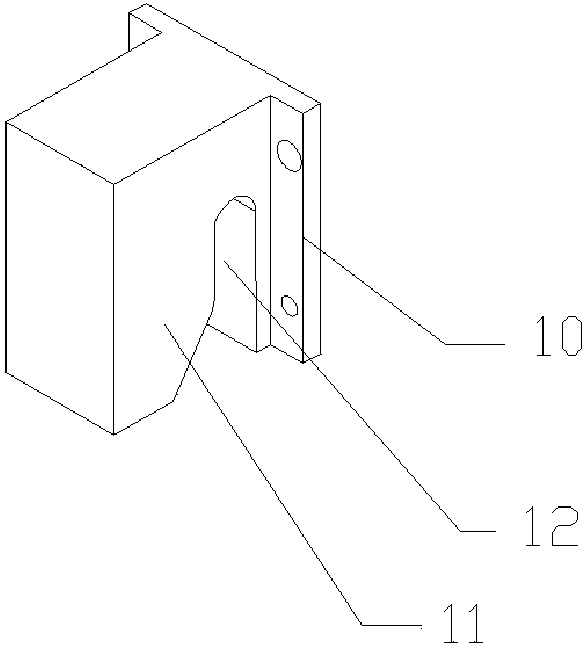

[0008] refer to Figure 1 to Figure 3 As shown, the gravity sliding mounting part includes a support seat 1, a support rod 2, a main hook part 3 and an auxiliary hook part; Insert the socket 5 of the support rod, the support rod 2 can be inserted into the socket. The main hook part 3 is composed of the main fixing seat 6 and the main slider 7 fixedly connected thereto, and the bottom surface of the main slider is upwardly provided with a main chute 8 matching with the support rod; the main chute It is bent or approximately bow-shaped, and the opening of the chute faces away from or deviates from the main fixed seat, and the opening of the chute is in the shape of a bell mouth for the entry of the support rod, and the main slider opposite to the bottom of the main chute is opened. There is an adjustment hole connected with the main chute, and an adjustment screw 9 is arranged in the adjustment hole. In addition, the auxiliary hook member includes an auxiliary fixing seat 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com