Shield receiving forward-shift construction method of boulder group open excavation and embedment mutation space

It is a technology of open-cut and buried-construction method, which is applied in excavation, foundation structure engineering, earthwork drilling and mining, etc. It can solve the problems of inability to carry out shield tunneling, reception and forward movement, etc., so as to eliminate the risk of downtime, facilitate construction, and reduce construction costs. The effect of digging depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

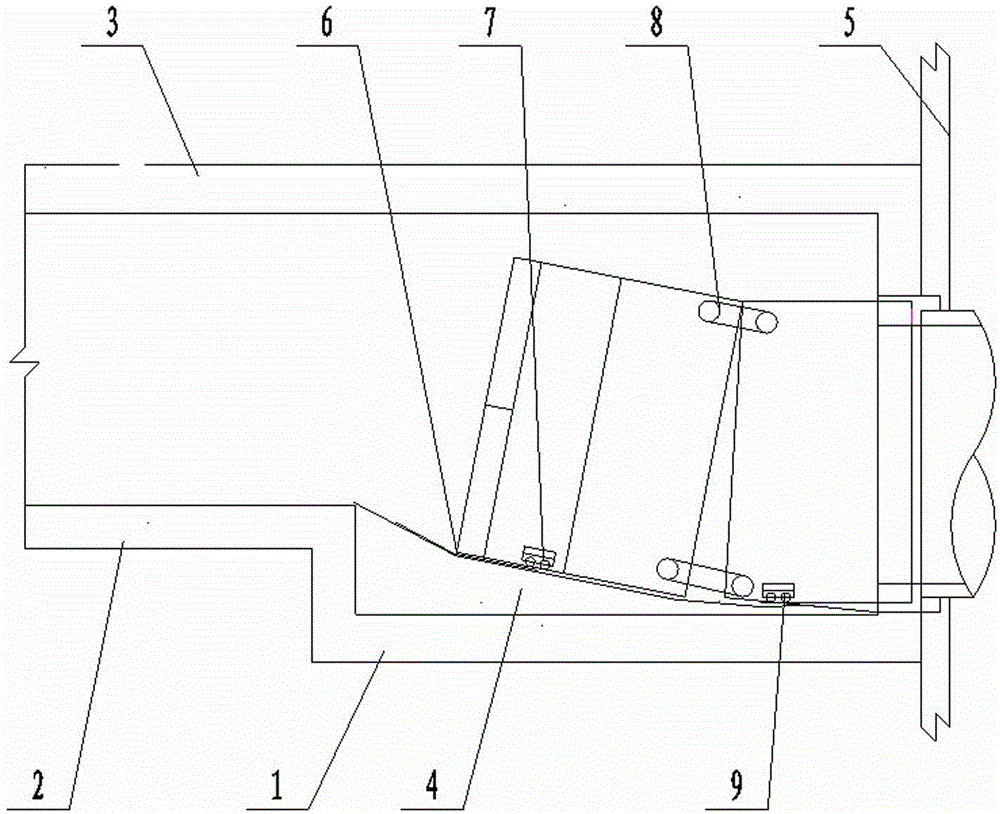

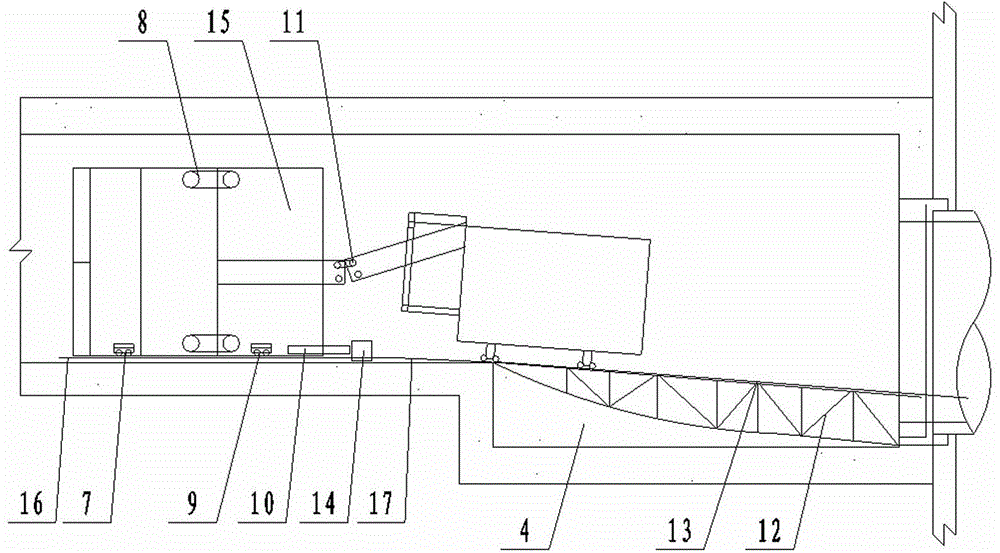

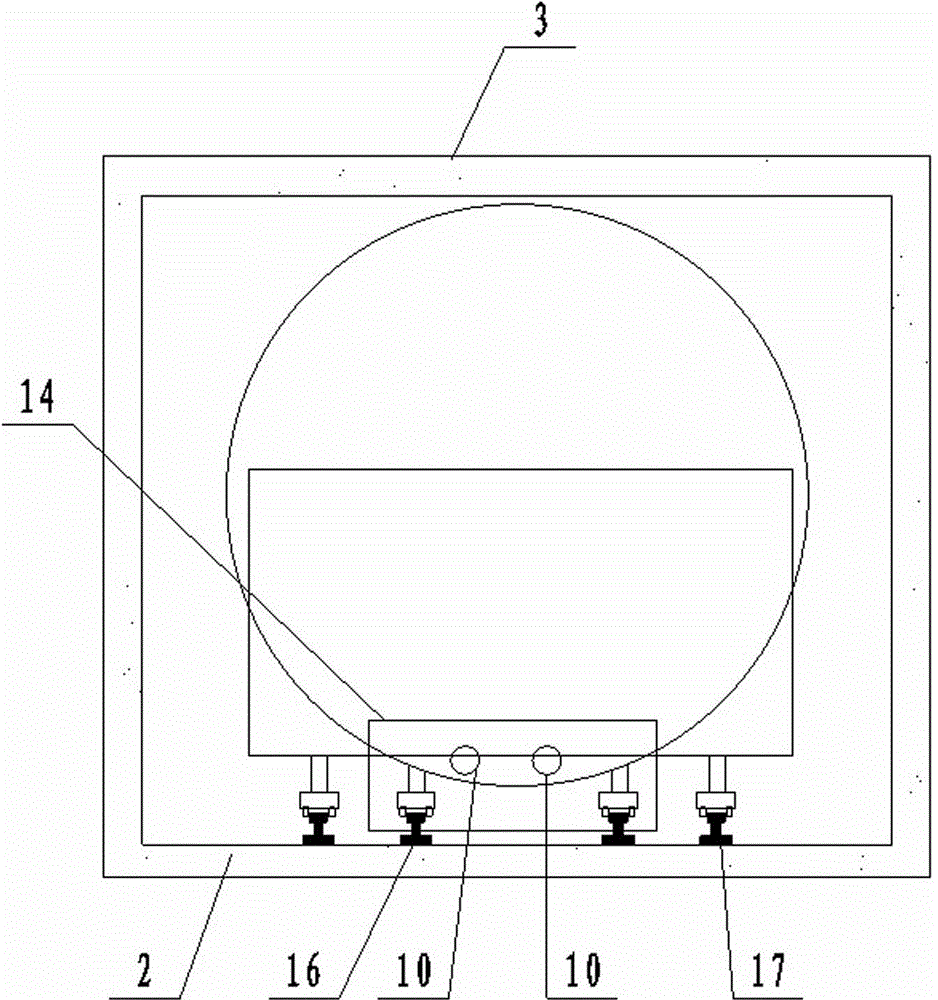

[0051] The shield section between Furong Square Station and Wuyi Square Station on Changsha Metro Line 2 Line 7 is a complex karst stratum. The 100 meters connected to Wuyi Square Station is a karst trench, and there are a large number of boulder groups, especially excavated through the station. It was revealed that the boulders were large, with irregular distribution and high density. After the detailed geological survey, the 100-meter-long section with a large number of boulders was changed to open excavation and buried construction. After receiving the shield, it was moved forward by empty push Hoist out at the reserved hoisting opening at Wuyi Square Station.

[0052] Since the bottom plate of the open excavation and buried section is 1.6 meters higher than the receiving bottom plate of the shield machine, it is impossible to carry out the traditional movement before the shield machine receiving. By backfilling the receiving shaft with concrete to form a transitional surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com