Base plate pre-alignment pose measuring method

A pose measurement and pre-alignment technology, applied in the direction of measuring devices, instruments, electrical components, etc., can solve the problem of low reproduction accuracy and achieve high reproduction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

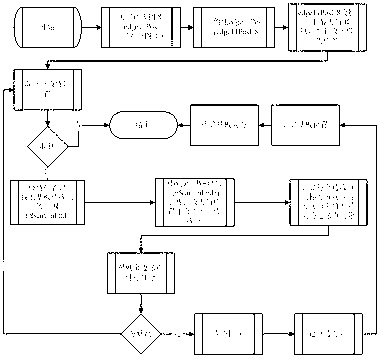

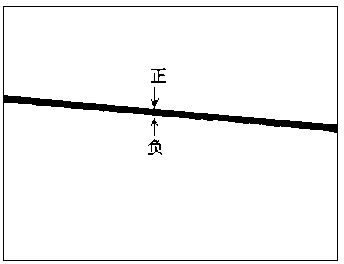

[0036] Use CCD or other image sensors to obtain the image of the substrate under test, refer to figure 2 As shown in , the convolution operation is performed through the vertical difference operator, and the resulting image is named edge. On the edge map, the gray value of most areas is 0 (or very small). in such as figure 1 There are some pixels whose gray level is greater than or less than 0 at the positive and negative positions. Ignore (set to 0) the part less than 0, that is, exclude the edge points from bright to dark from top to bottom, and only keep the points whose difference value is greater than 0, thus excluding the influence of negative edge points, and get the image edge11Pos ,Such as image 3 shown.

[0037] Horizontally project the edge11Pos image after binarization. Since photolithography will not be performed within 5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com