Pulse width modulation (PWM) hysteresis control method based on ripple

A hysteresis control and ripple technology, applied in the field of DC switching power supply control, can solve problems such as difficult control circuit design, complex compensation circuit design and debugging, and reduced dynamic characteristics, so as to achieve good load disturbance resistance and dynamic characteristics, eliminate Phase delay problem, the effect of reducing the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

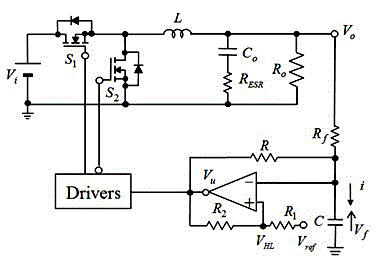

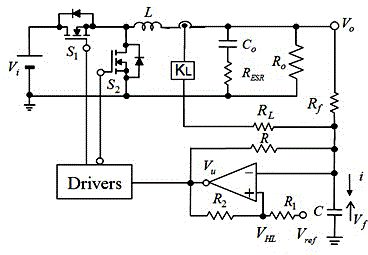

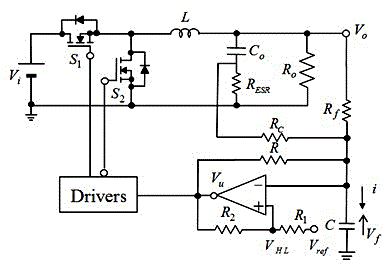

[0026] Such as figure 1 Shown is the traditional hysteresis control method diagram, V o Is the output voltage; Io is the load current; R o for the load; R f and R Adjust resistors for feedback; V i is the input voltage; S 1 , S 2 MOSFET is the switching tube; L is the filter inductance; C is the capacitance; V f for capacitance C voltage on C o is the filter capacitor; R ESR is the parasitic resistance of the filter capacitor, V ESR is the parasitic resistance of the filter capacitor R ESR on the voltage; V L and V H The hysteresis comparator threshold voltage (low level, high level) is in the figure V HL , V ref is the reference voltage;R 1 ,R 2 Adjust resistors for upper and lower thresholds. The positive and negative ends of the input DC power supply are connected in series with two MOSFET switch tubes S 1 and S 2 , the driver is connected to two MOSFET switch tubes S 1 and S 2 Control pole, the series connection point of two MOSF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com