Filter tip with gaps and patterns

A filter rod and gap technology, which is applied in the field of gap pattern filter rods, can solve the problems of complex manufacturing process, high cost, and large waste, and achieve good anti-counterfeiting effect and novel and unique appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

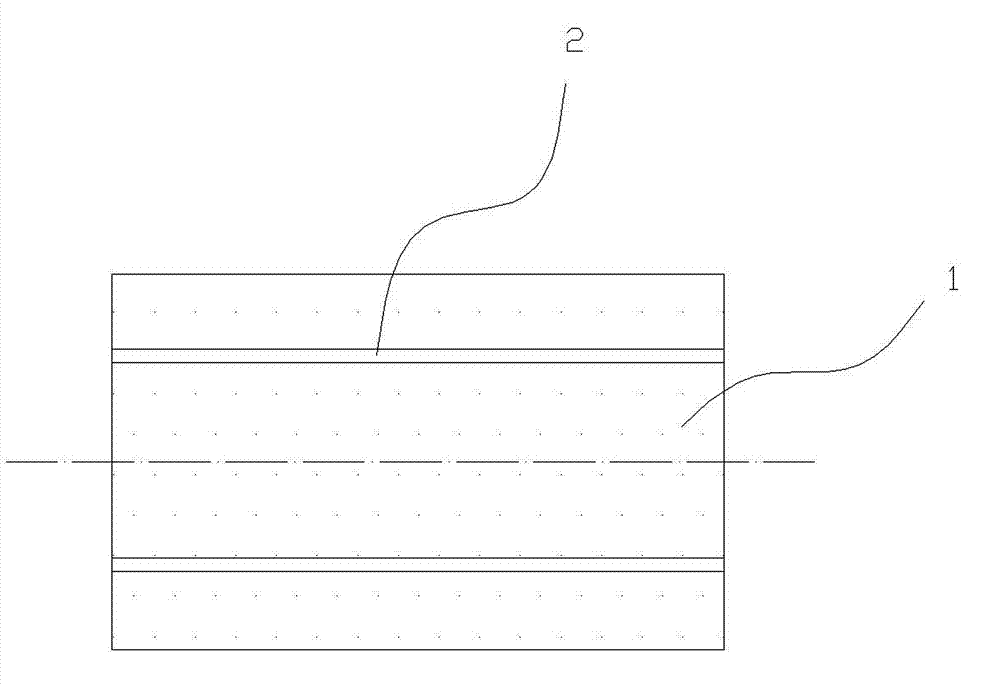

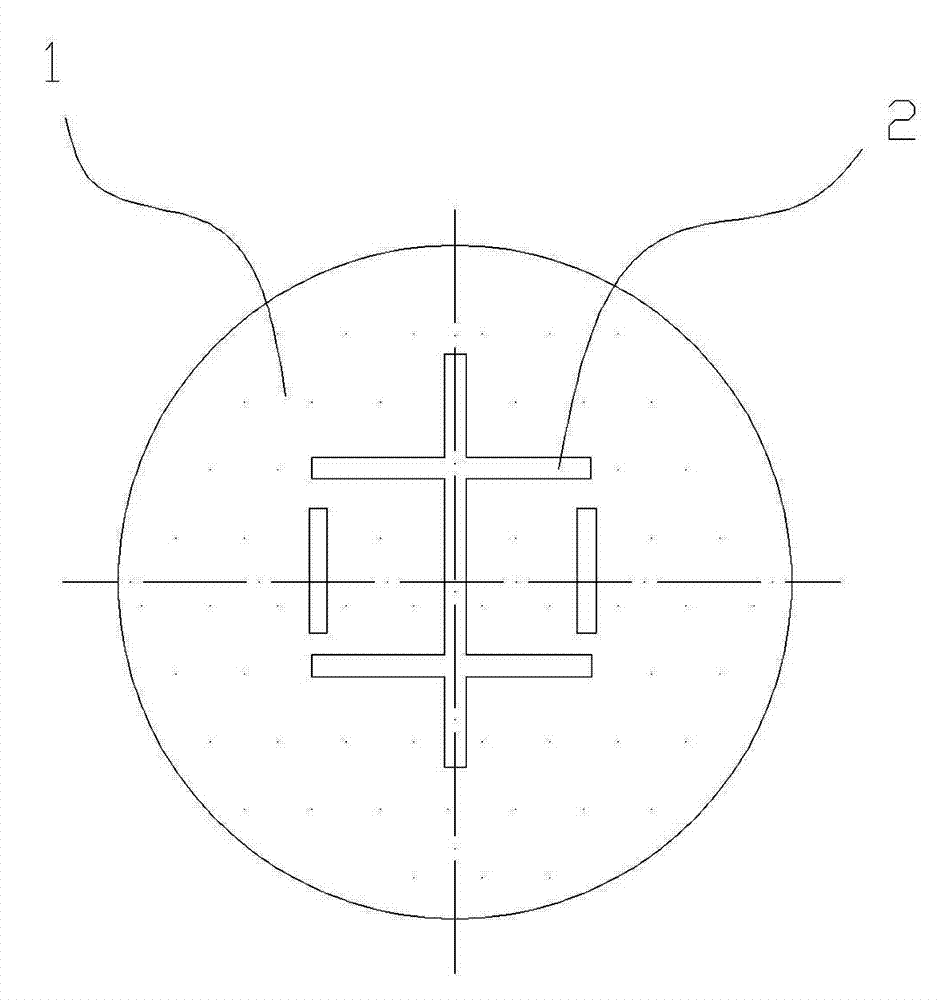

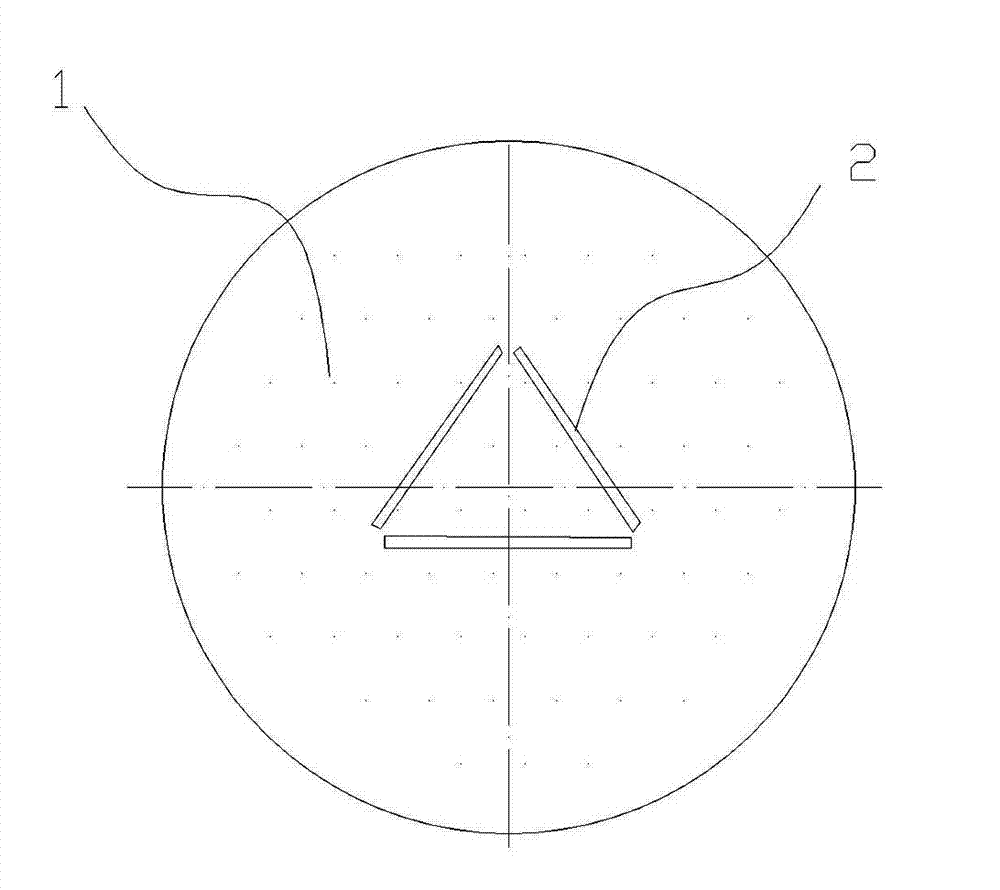

[0017] Such as figure 1 As shown, the present invention provides a gap pattern filter rod, in which a group of gaps 2 are formed in the axial direction in the tow mandrel 1 , and the gaps form a certain pattern on the end surface of the tow mandrel 1 . The graph can be as in figure 2 The Chinese character graphics shown can also be as image 3 Set the shape as shown in the triangle and so on.

Embodiment 2

[0019] Such as Figure 4 As shown, the tow mandrel 1 with a gap pattern of a certain length specification is arranged together with the filter rod 3 of a certain length specification, and then they are wrapped with molding paper 4 to form a composite filter tip with a gap pattern Great. The composite filter rod not only has a good defocusing effect, but also has a good aesthetic effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com