Atomization device and nozzle thereof

A technology of atomization device and nozzle, which is applied in the direction of injection device, liquid injection device, nebulizer for treatment, etc. It can solve the problems of inconvenient to carry and use, larger size, large power consumption, etc., and achieve the purpose of improving the fog The effect of chemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Existing nozzles have too much resistance and require a high-power air pump, which not only causes noise interference, consumes a lot of power, but also increases in size, making it inconvenient to carry and use.

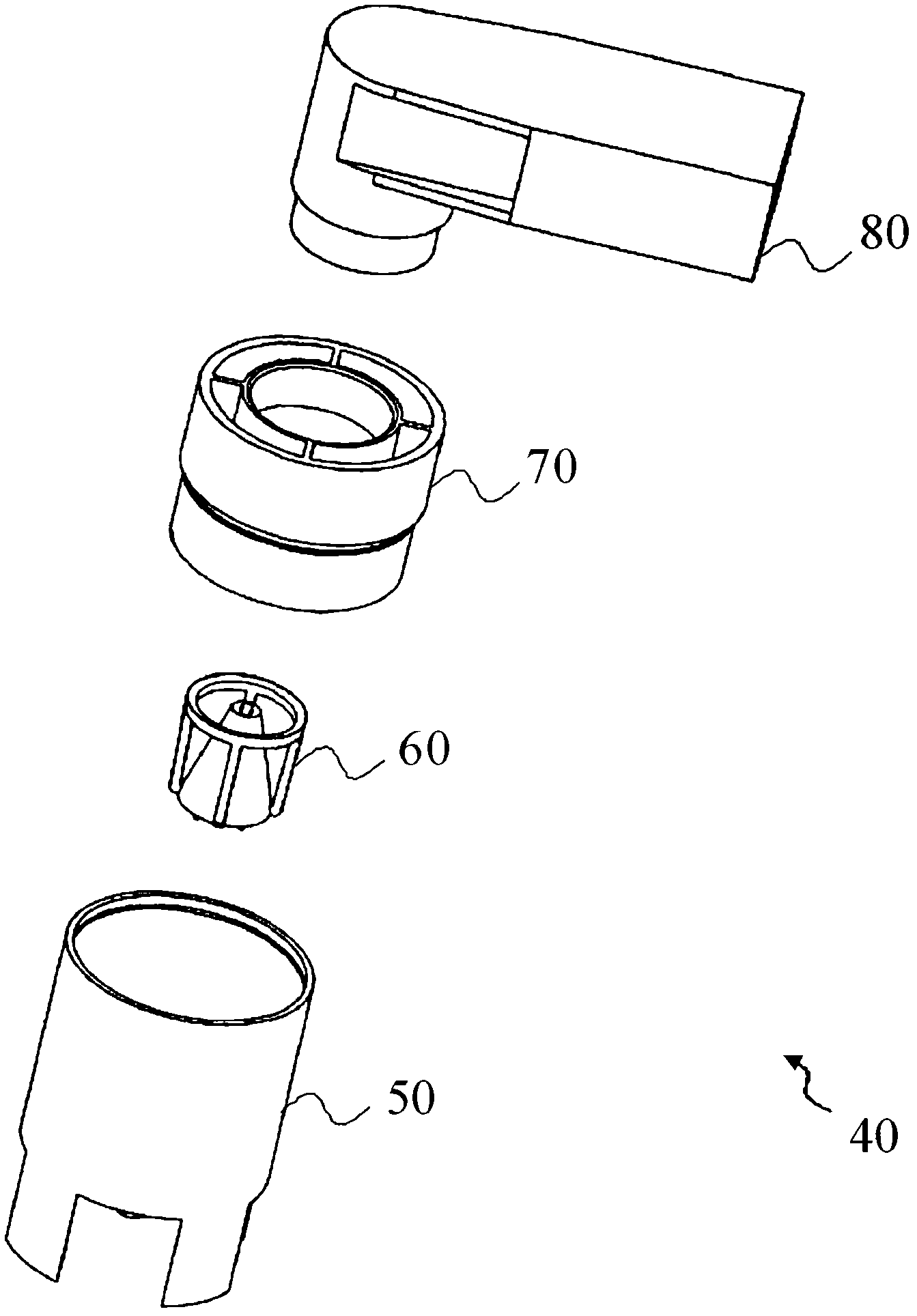

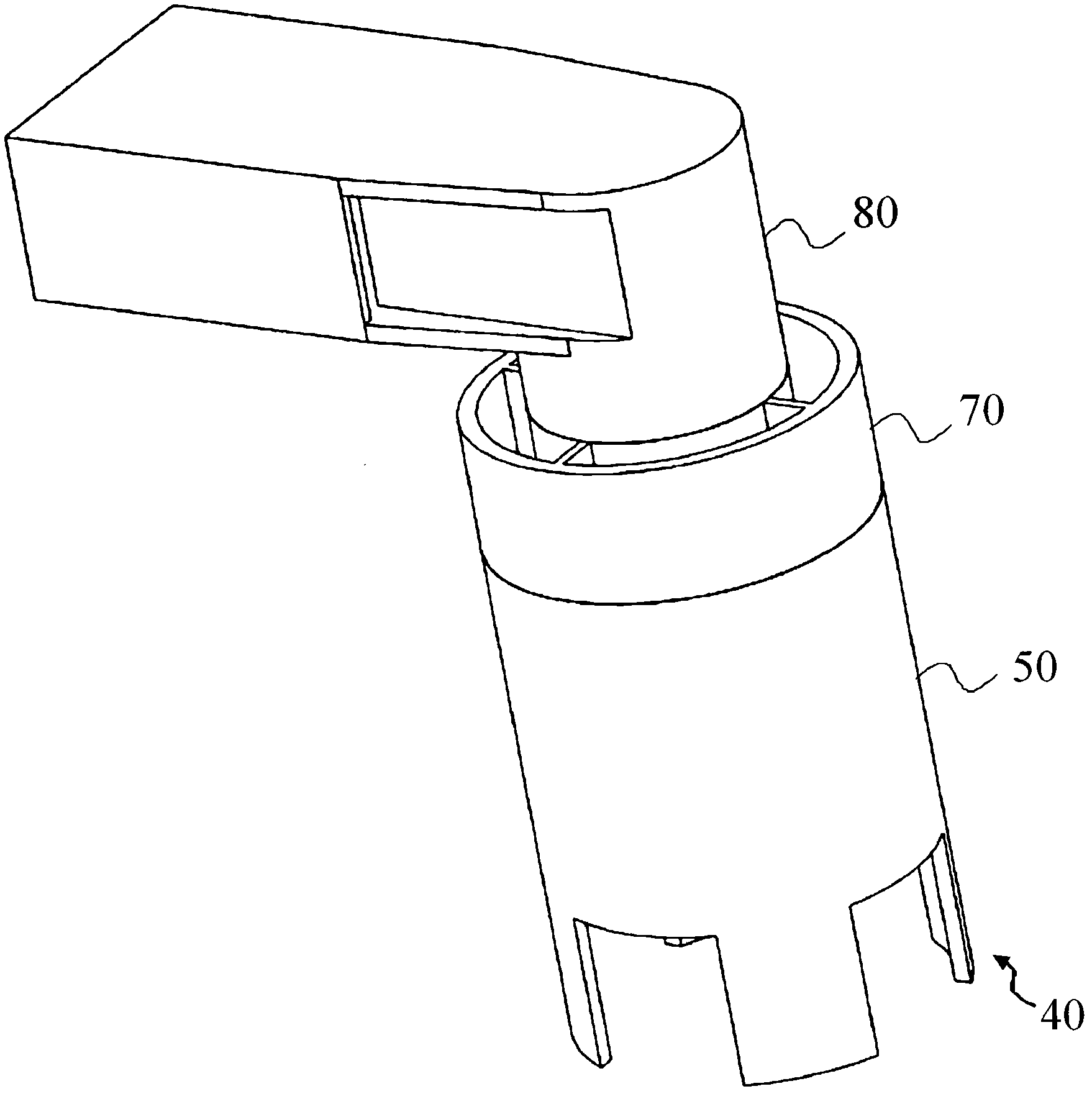

[0047] In contrast, embodiments of the present invention provide an atomizing device and a nozzle thereof. Generally speaking, if the resistance of the nozzle is concentrated in some structures, the overall resistance will increase. The embodiments of the present invention balance the resistance and atomization efficiency of each part of the nozzle, and the atomization function of the nozzle can be driven by a low-power air pump. The nozzle seat is equipped with an air inlet opening. When the gas is ejected from the outlet end, the gas in the inlet opening will be diverted to the air outlet end, which can reduce the resistance. In addition, a blocker with a protruding curved surface is arranged in front of the gas outlet, wherein the protruding curved surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com