Spring dynamic process device

A process device and dynamic technology, which is applied in the process, decorative art, decorative structure and other directions for producing decorative surface effects, can solve the problems of easy falling off and dynamic, and achieve the effect of obvious dynamic effect and strong three-dimensional effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

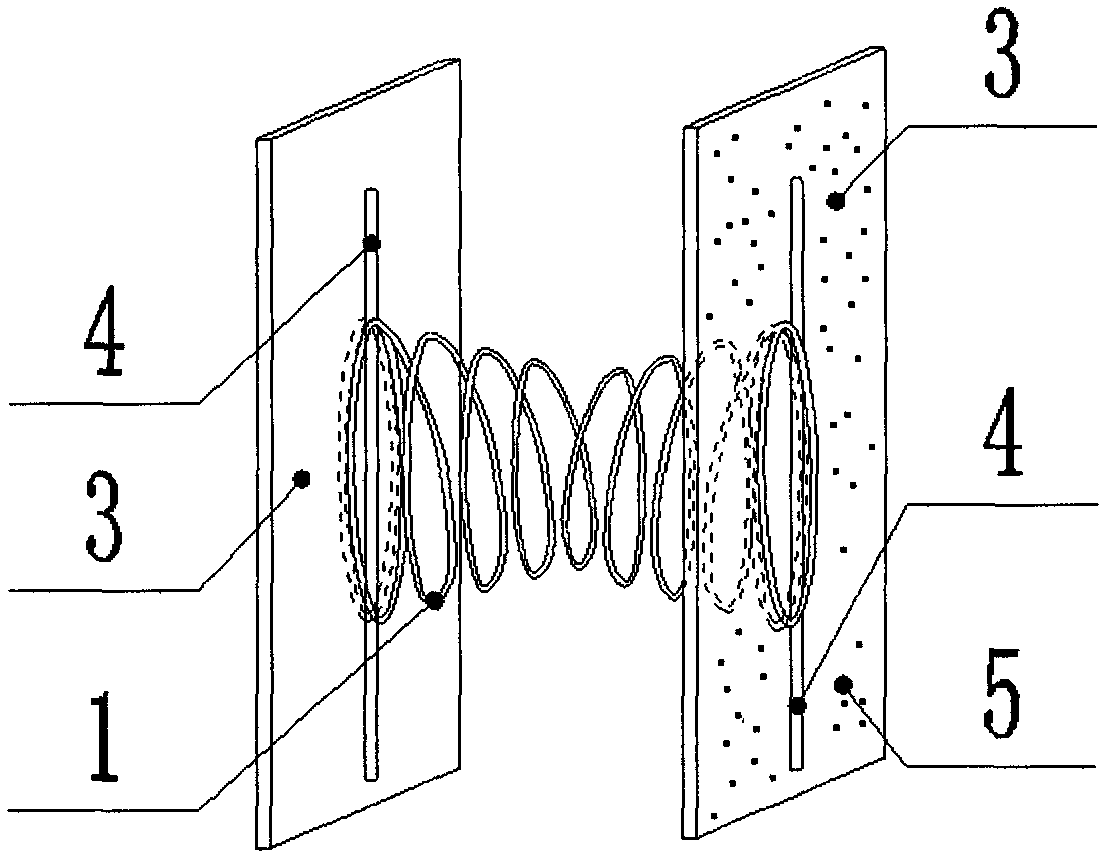

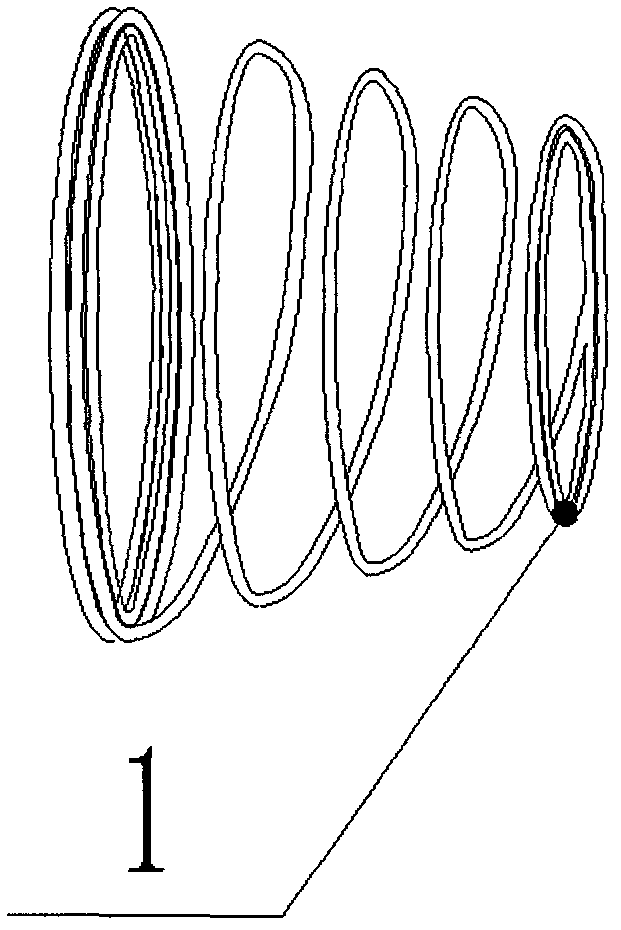

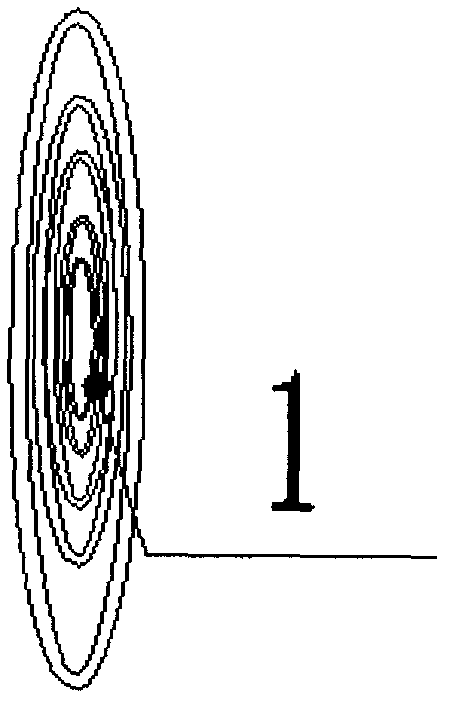

[0030] A spring dynamic process device, including spring 1, square spring mouth 2, spring clasp 3, spring clasp mouth 4, viscose layer 5, sleeve position 6, sleeve mouth 7. The main point is that spring 1 has square spring mouths at both ends 2. The spring clasp 3 has a socket 6 and a socket 7, the square spring socket 2 on the spring 1 is buckled or fitted through the socket 7 on the spring clamp 3 and the spring clamp 3, the square on the spring 1 After the spring port 2 is buckled into the spring buckle 3 through the sleeve port 7, the spring buckle 3 is pasted by brushing a layer of glue 5, and the round spring port on the spring 1 passes through the spring buckle on the spring buckle 3. The opening 4 buckles or sleeves the spring 1 into the spring buckle 3, and the buckled or sleeved spring 1 is stuck between the first layer 8 and the second layer 9 through the adhesive layer 5 on the spring buckle 3. Between the second level 9 and the third level 10. The spring clasp 3 c...

Embodiment 2

[0032] There are patches 11 on the first layer 8 and the second layer 9 and the third layer 10, the patch 11 has a patch spring sleeve 12 and a patch spring sleeve 13, and the patch 11 is pressed on the first layer by high temperature. On the layer 8, the second layer 9 and the third layer 10, the patch 11 can also be adhered to the first layer 8, the second layer 9, and the third layer 10 by glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com