Tail portion folding device of plastic bag automatic folding strapping machine

A folding device, a technology of plastic bags, applied in packaging, paper product packaging, transportation and packaging, etc., can solve the problems of not easy to fold, not square, easy to rebound, etc., and achieve the effect of simplified working procedures, simple structure, and reduced rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

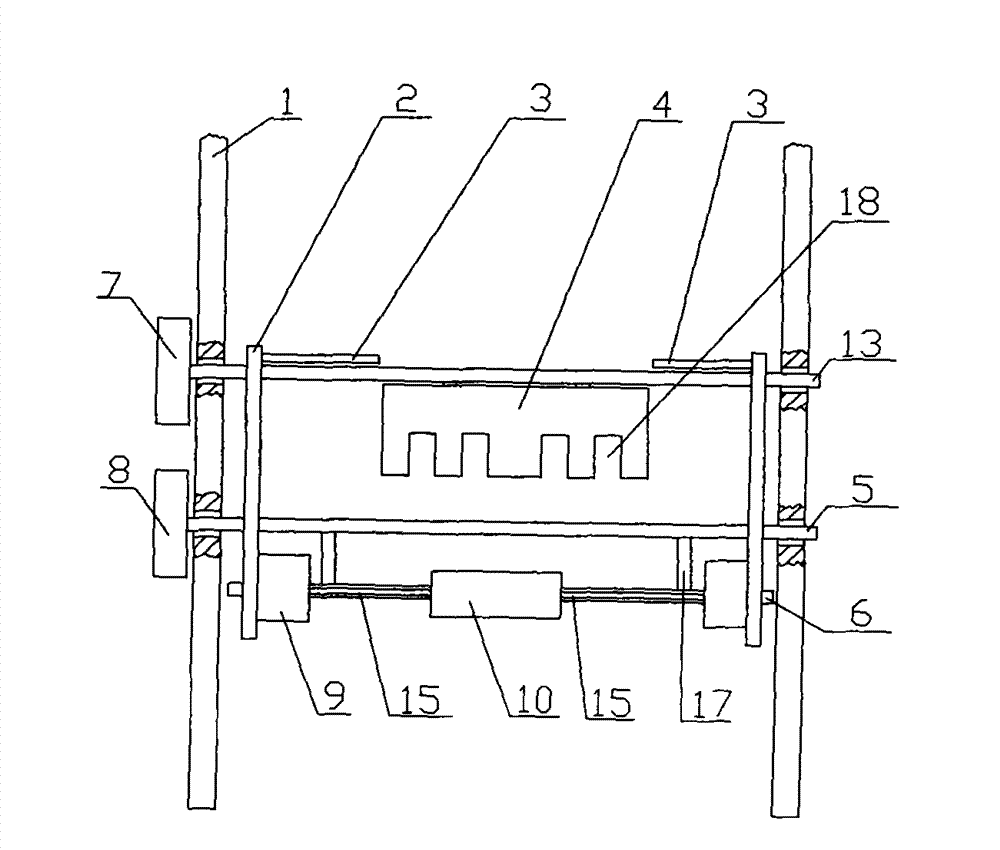

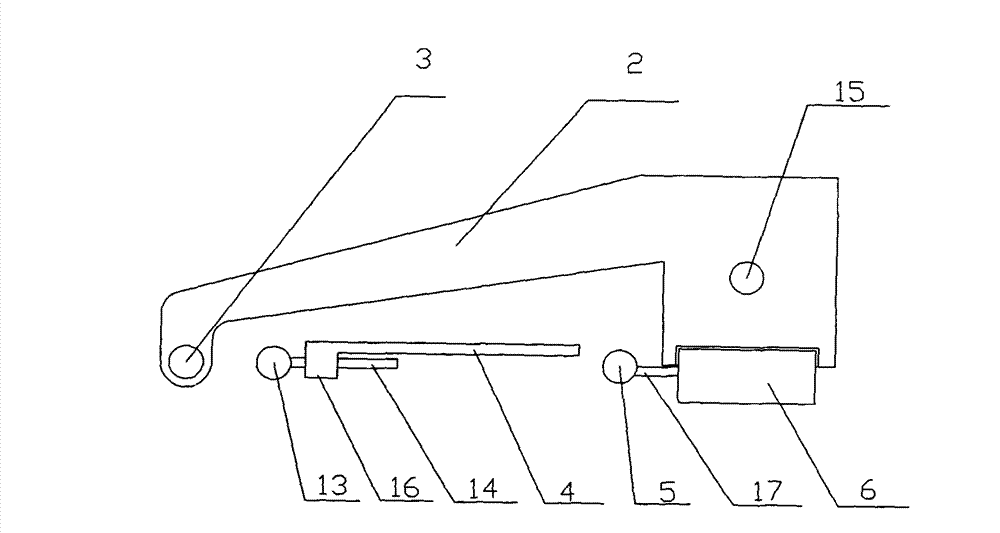

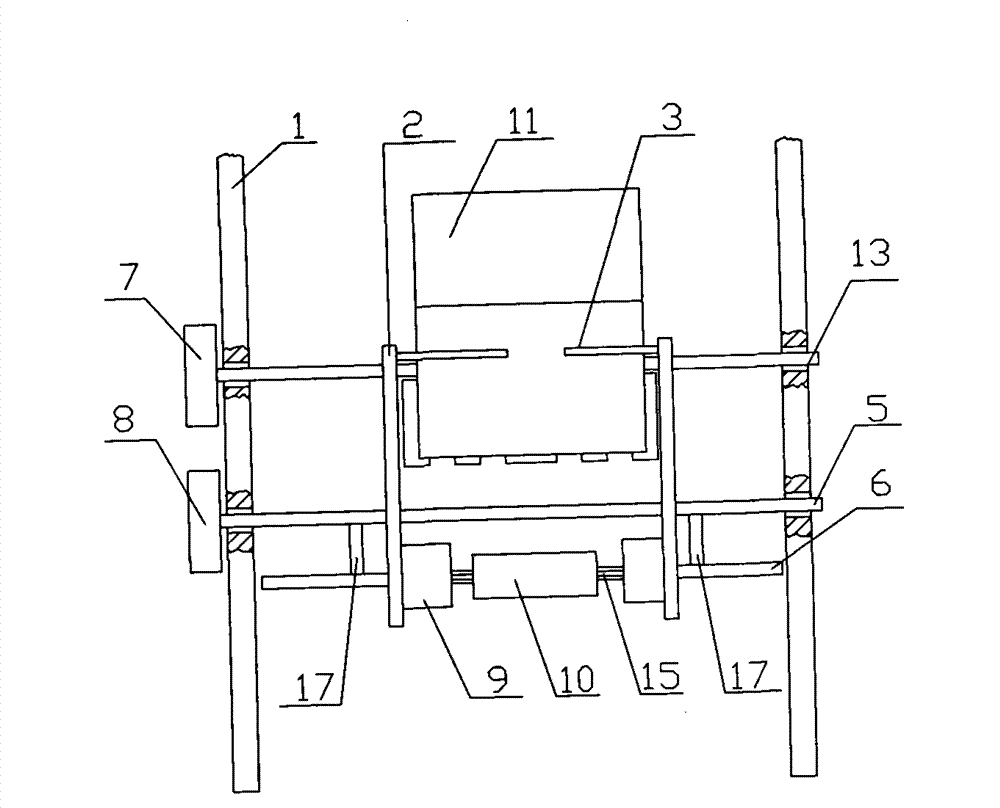

[0017] Attached below figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Figure 6 , attached Figure 7 , to further illustrate the present invention. A kind of tail folding device of the automatic folding and binding machine for plastic bags described in this embodiment includes a frame 1, on which a turning plate rotating shaft 13 is horizontally installed, and is installed on the frame corresponding to one end of the turning plate rotating shaft The swinging cylinder 7 of the turning plate is connected with the rotating shaft 13 of the turning plate. When the cylinder 7 of the turning plate is working, it can drive the swinging plate 4 to swing back and forth 180 degrees; Axle 14, turn over plate 4 is installed on the slide shaft 14 by its sliding sleeve 16, make turn over plate 4 can freely slide back and forth on slide shaft 14, turn over plate cylinder 12 is installed on the back side of turn over plate 4, when tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com