Packaging carton packaging operation adhesive tape box sealing device

A carton and adhesive tape technology, applied in the field of tape sealing device for packing cartons, can solve the problems of inconvenient multiple sets of boxes, adjustment of packing and sealing operations, etc., and achieve the effects of easy disassembly and replacement, convenient use and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

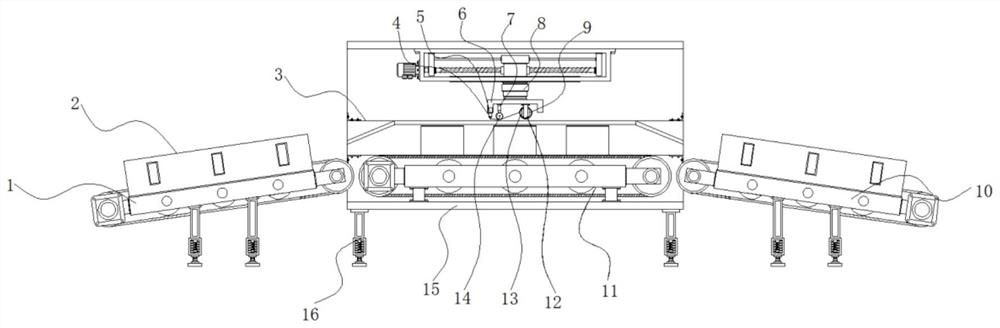

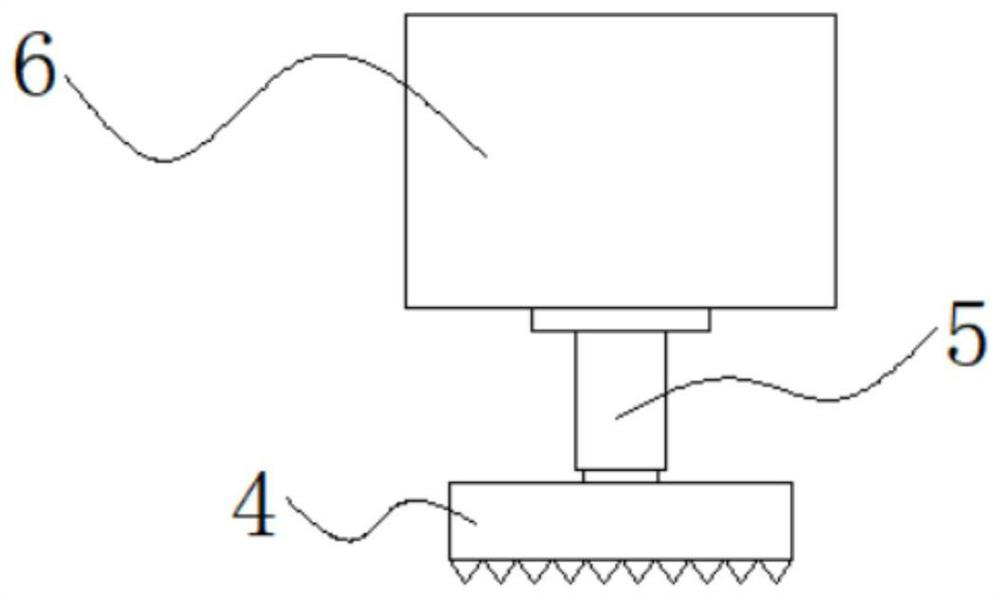

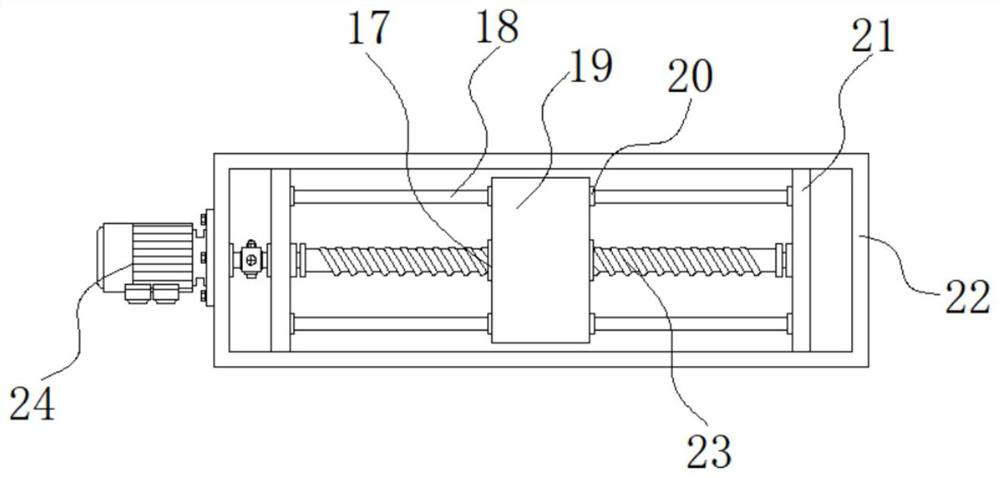

[0037] Example 1: See Figure 1-8 , a kind of tape sealing device for packing cartons, including a casing 15, four corners of the bottom of the casing 15 are respectively fixedly connected with supporting legs 16, one side of the casing 15 is provided with a feeding conveyor belt 1, and the other side of the casing 15 The side is provided with a blanking conveyor belt 10, the top ends of the loading conveyor belt 1 and the blanking conveyor belt 10 are respectively provided with a protective limit structure 2, and a folding structure 3 is arranged horizontally at the middle position inside the shell 15, and the top of the shell 15 is A cylinder 8 is provided at the middle position of the cylinder, the model of the cylinder 8 can be MPT, and the bottom end of the cylinder 8 is fixedly connected with the installation frame 6, and the inside of the bottom end side of the installation frame 6 is fixedly connected with the first electric push rod 5, the The model of the first elect...

Embodiment 2

[0041] Embodiment 2: The protective limit structure 2 is composed of an outer guard plate 201, an inner sleeve 202, a limit block 203, a movable rod 204, a swivel 205, a fixed frame 206, a rotating rod 207 and a fixed seat 208. The outer guard plate 201 is respectively Fixedly connected to the top ends of the feeding conveyor belt 1 and the protective limit structure 2, the two sides and the middle position inside the outer guard plate 201 are respectively fixedly connected with a fixed seat 208, and one end of the fixed seat 208 is fixedly connected with an inner sleeve respectively. 202, one end of the inner sleeve 202 is movably connected with a swivel 205 respectively, and the inside of the swivel 205 is respectively provided with a movable rod 204, and one end of the movable rod 204 runs through the inside of the swivel 205 and extends to one end of the inner sleeve 202, the inner sleeve One end of 202 is respectively fixedly connected to the limit block 203, and the other...

Embodiment 3

[0044] Embodiment 3: The folding structure 3 is composed of an outer cover 301, a fixing chamber 302, an inner groove 303 and an arc block 304. The outer cover 301 is fixedly connected to the bottom of both sides inside the shell 15 in a horizontal direction, and the middle position of the inner top of the outer cover 301 is fixed in a horizontal direction. There is a fixed chamber 302, and the inside of the fixed chamber 302 is provided with a shaping groove 305 horizontally, and an inner groove 303 is arranged horizontally at the middle position inside the top of the fixed chamber 302, and the two ends of the top inside the outer cover 301 are respectively fixedly connected with arc-shaped blocks 304 ;

[0045] The top of the shaping groove 305 communicates with the inside of the inner groove 303, and the arc block 304 is an inclined plane block;

[0046] Specifically, such as figure 1 , Figure 5 and Image 6 As shown, when the carton after preliminary packaging and seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com