Process for preparing narrow-distribution chitosan with controllable molecular weight through microwave-H2O2 combined degradation method

A -H2O2, chitosan technology, applied in the field of preparation of water-soluble chitosan, can solve the problems of complex post-processing, difficult acquisition, purification and immobilization, harsh requirements, etc., and achieves clear molecular weight distribution characteristics, effective control of molecular weight distribution, The effect of saving energy and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 2.00g of chitosan into the reactor, add 30mL of 1% (w / w) acetic acid and stir to dissolve, after standing for 10min, add 6% (w / w) H 2 o 2 30mL was placed in the microwave reactor and equipped with a reflux device, and stirred evenly; set the microwave radiation temperature to 65°C, the radiation anode current to 80mA, and turned on the microwave pulse radiation; start the radiation timing, and control the effective radiation time for 3 minutes. After the reaction, cool to room temperature, adjust the pH to 7~8 with 5% (w / w) sodium hydroxide solution, filter to remove a small amount of residue, precipitate the filtrate with 2.5 times the volume of absolute ethanol, collect the precipitate, and vacuum at 40°C Dry to obtain water-soluble oligomeric chitosan; the measured yield is 55%, the average molecular weight of the product is 7255, and the polydispersity coefficient D is 1.6, which belongs to a narrow distribution product.

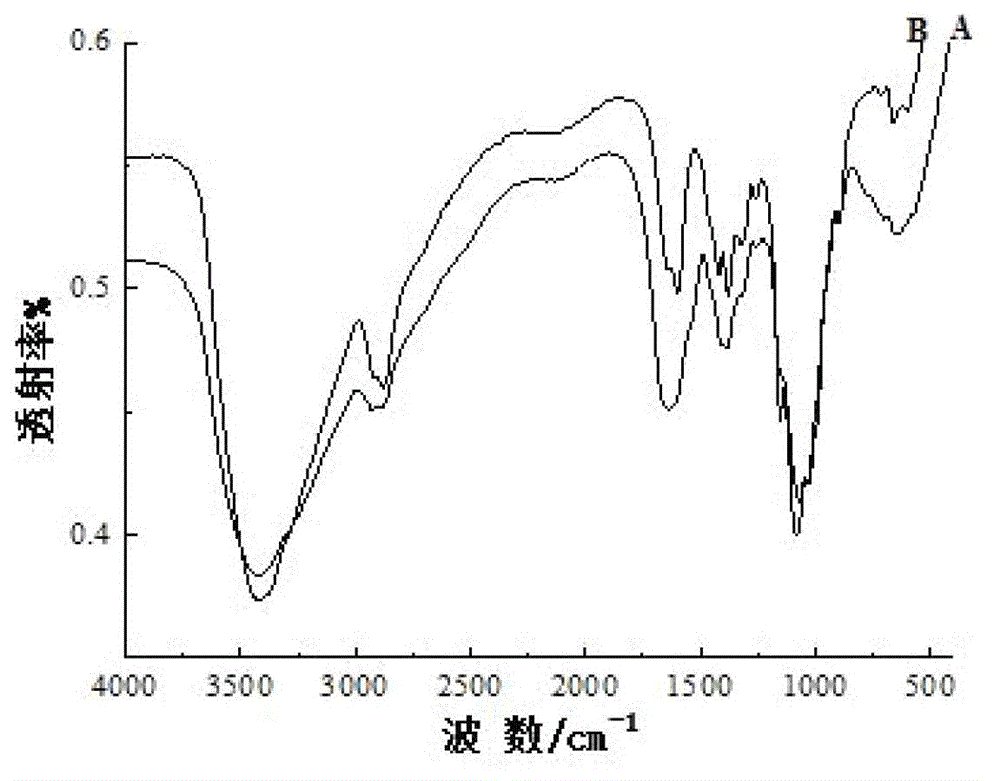

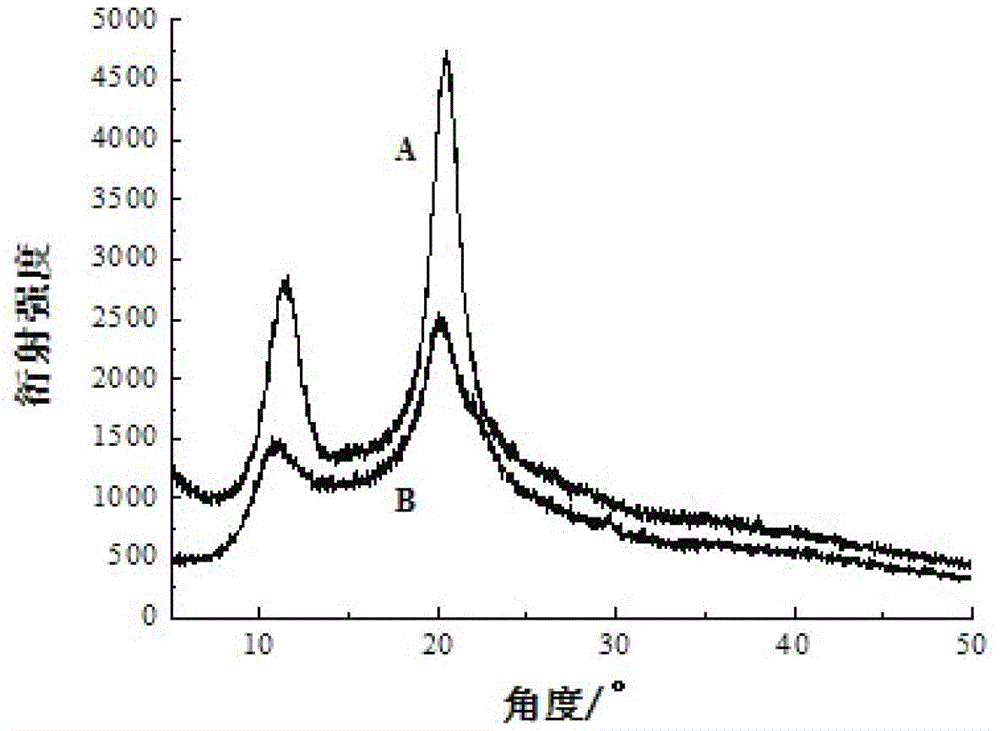

[0026] The infrared spectrograms of ...

Embodiment 2

[0034] Weigh 2.00g of chitosan into the reactor, add 30mL of 1% (w / w) acetic acid and stir to dissolve, then add 2% (w / w) H 2 o 2 30mL was placed in a microwave reactor and equipped with a reflux device, and stirred evenly; set the microwave radiation temperature to 50°C, the radiation anode current to 40mA, and turned on microwave pulse radiation; control the effective radiation time for 3 minutes. After the reaction, cool to room temperature, adjust the pH to 7~8 with 5% (w / w) sodium hydroxide solution, remove a small amount of residue by filtration, precipitate the filtrate with 2 times the volume of absolute ethanol, collect the precipitate and dry it under vacuum at 40°C , to obtain water-soluble oligomeric chitosan; the measured yield was 49%, the average molecular weight of the product was 18229, and the polydispersity coefficient D was 1.8, which belonged to narrow distribution products.

[0035] The preparation process of this example was repeated at least five times...

Embodiment 3

[0038] The steps are the same as in Example 2, except that the effective radiation time is controlled for 5 minutes to obtain water-soluble chitosan oligosaccharides; the measured yield is 52%, the average molecular weight of the product is 6560, and the polydispersity coefficient D is 1.8, which belongs to a narrow distribution product .

[0039] The preparation process of this example was repeated at least five times, and the measured yields were all about 52%, the average molecular weight of the products was 6560-8407, and the polydispersity coefficient D was between 1.8-2.0, all of which were narrowly distributed products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com