Integral linear drainage ditch

An integrated, drainage ditch technology, applied in the field of drainage ditch, can solve problems such as easy separation, and achieve the effects of improving the ability to resist lateral impact, protecting driving safety, and having strong bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

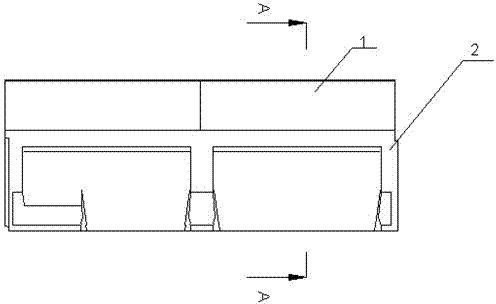

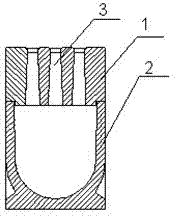

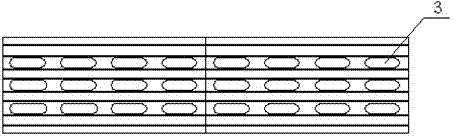

[0019] Embodiment: An integrated linear drainage ditch, including a ditch body 1 and a cover plate 2. A number of drainage holes 3 are formed on the cover plate 2. The cover plate 2 covers the upper end of the opening side of the ditch body 1. The cover plate 2 and the ditch body 1 The one-piece structure is formed by fixing and bonding with glue, and the ditch body 1 and the cover plate 2 have an integrated structure. During the high-speed driving of the vehicle, there is no displacement or springboard phenomenon of the cover plate 2, and it is safe to use and has no noise.

[0020] Based on the actual use direction, the opening side of the groove body 1 forms a stepped groove that expands outward in the width direction, and the lower end of the cover plate 2 forms a protrusion that shrinks in width, and the protrusion at the lower end of the cover plate 2 is just inserted into the The upper end of the ditch body 1 is open in the groove, and the stepped surface formed by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com