Constant-force gate valve

A gate valve and constant force technology, which is applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of shortening the service life of gate valves, the cone is easy to wear, and the opening size cannot be controlled, so as to prolong the service life and reduce the closing force , Open and close the effect of small force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

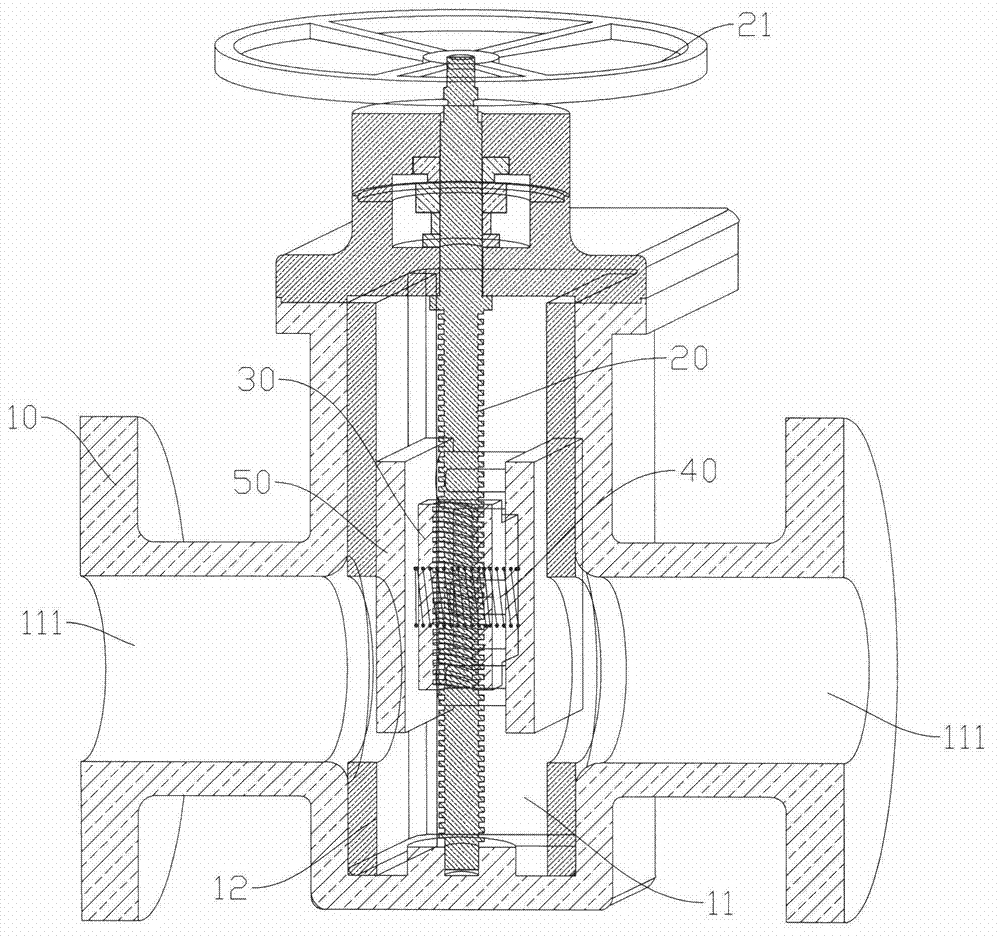

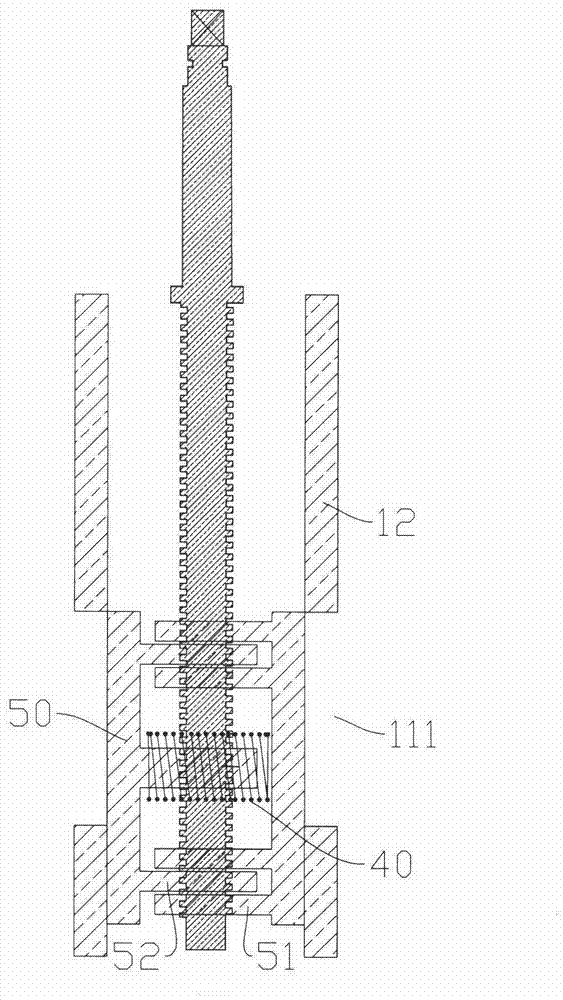

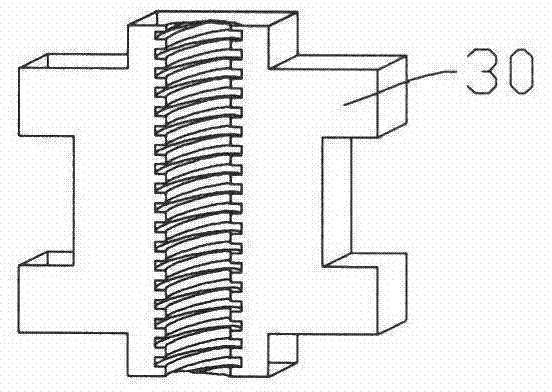

[0015] Examples, see Figure 1 to Figure 3 Shown: constant force gate valve, including valve body 10. The valve body 10 is provided with an inner chamber 11 , and the left and right ends of the inner chamber 11 are connected with water ports 111 . That is, the two water ports 111 are used to flow in and out the liquid medium. Both left and right sides of the inner cavity 11 are provided with sealing surfaces 12 . Certainly, the sealing surface 12 can be integrally formed with the valve body 10 , or can be fixed in the inner cavity 11 by means of screws or the like. The inner cavity 11 is pivotally connected with a valve stem 20, and the valve stem 20 is connected with a power device. That is, under the action of the power device, the valve stem 20 can rotate. At the same time, non-rotatable seals 50 are provided on the left and right sides of the inner cavity 11 , and the outer surfaces of the two seals 50 match the two sealing surfaces 12 respectively. The so-called matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com